Automatic tidying machine

A strip material and automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem that the machine cannot realize automatic feeding and discharging, and consumes a lot of manpower, and achieves novel structure, simple feeding and guarantee. The effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

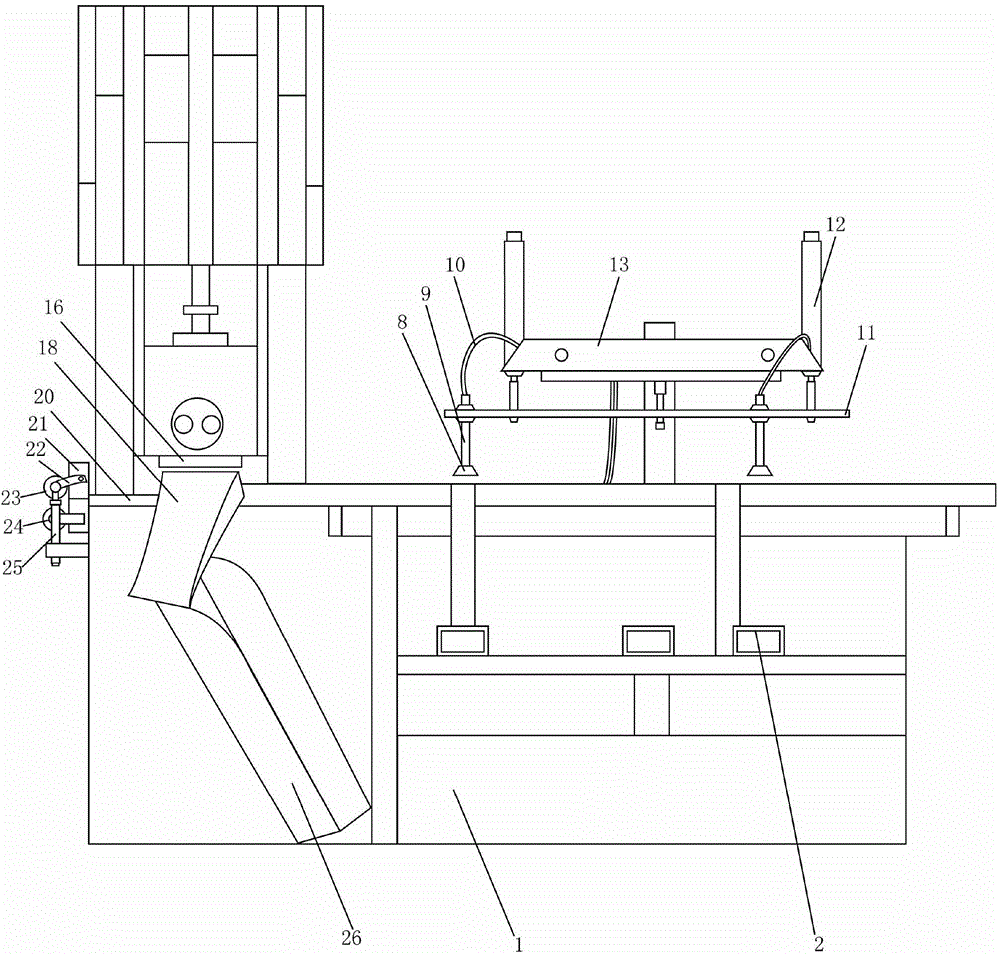

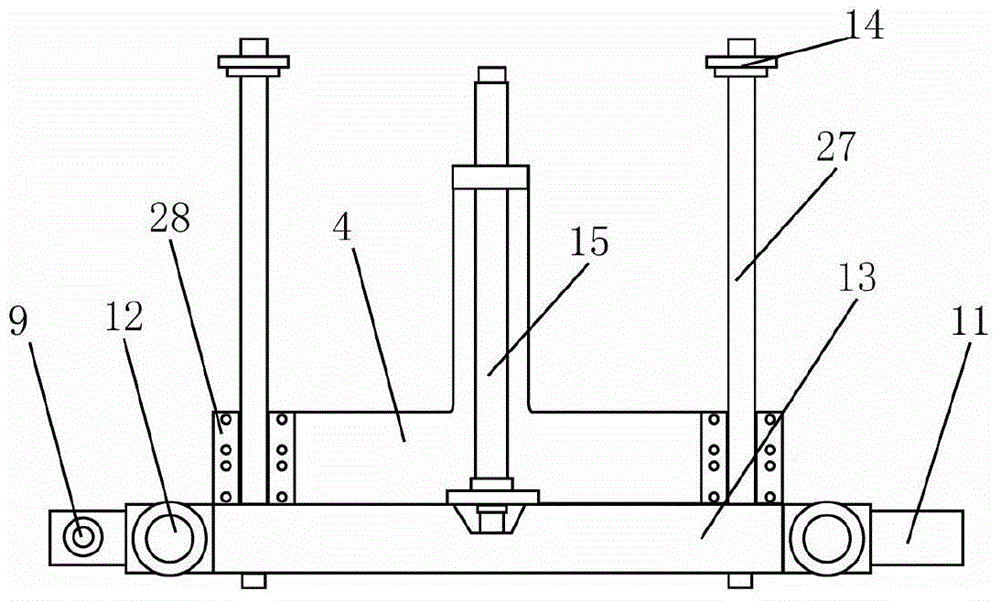

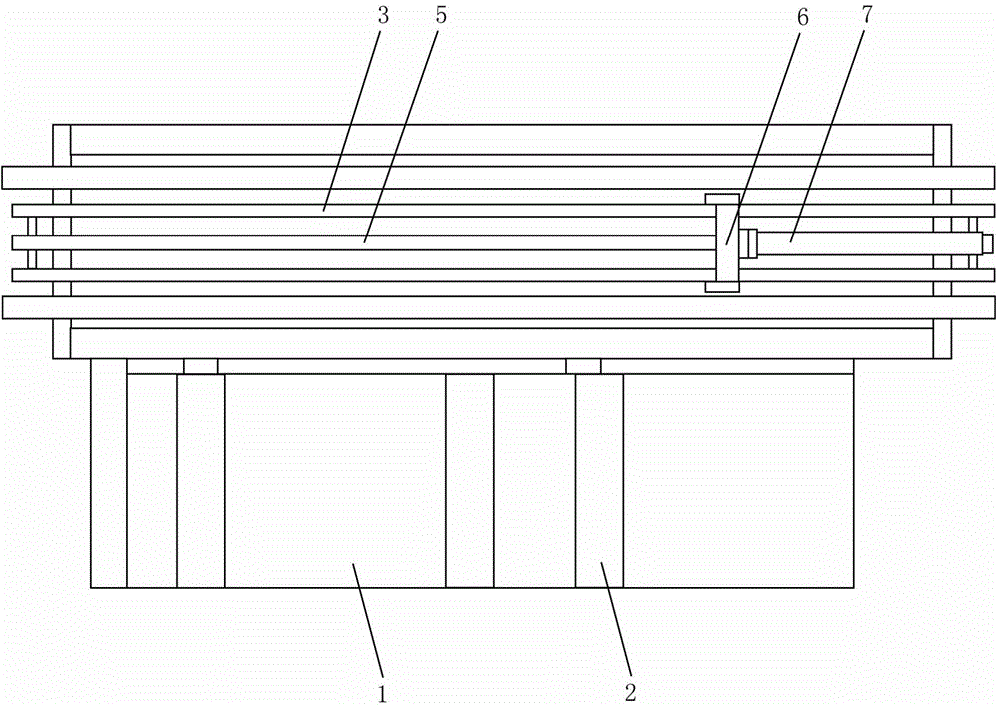

[0031] Such as Figure 1-5 As shown, an automatic strip machine includes a frame 1, a tank cover bracket 2, a screw nut slide rail 3, a fixed frame push plate 4, a lead screw 5, a lead screw nut 6, a lead screw nut cylinder 7, and a suction cup 8. Air pipe 10, connecting piece fixing plate 11, connecting piece fixing plate cylinder 12, connecting piece fixing plate cylinder fixing frame 13, fixing frame pushing plate 4, fixing frame pushing cylinder 15, stamping upper mold 16, stamping lower mold 17, finished product Discharge guide cylinder 18, air blowing pipe 19, waste guide rail 20, movable discharge roller fixing plate 21, movable discharge roller connecting plate 22, movable discharge roller 23, fixed discharge roller 24, movable discharge roller cylinder 25, tank The cover bracket 2, the lead screw nut slide rail 3, and the fixing frame push plate 4 are installed on the frame 1, the lead screw nut slide rail 3 is located on one side of the tank cover bracket 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com