Grain wetting method in sauce fragrance baijiu brewing technology

A Maotai-flavor liquor and process technology, applied in the preparation of alcoholic beverages, can solve the problems of short standing time, inability to achieve gelatinization, and difficulty in achieving the effect of moistening grains, and achieve simple process, increase water absorption, and promote pasteurization. effect of chemical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

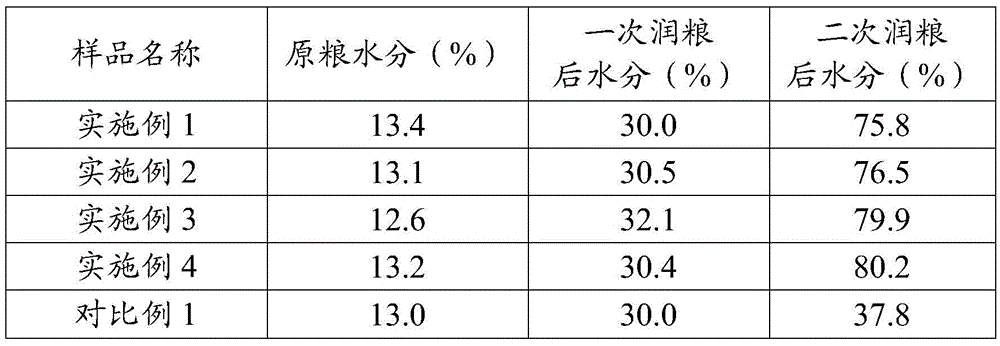

Examples

Embodiment 1

[0036] A grain moistening method in the brewing process of Maotai-flavor liquor, comprising the steps of:

[0037] (1) Prepare tools and grain raw materials; the grain raw materials use sorghum granules as the main brewing raw materials; every 900kg-1000kg of grain raw materials is a pile;

[0038] (2) When the temperature of the grain moistening water is not lower than 95°C, the first grain moistening is started; the grain raw materials are carried out in batches for the first grain moistening, and the quality of each batch of grain raw materials is 80-100kg. The grain moistening grain raw materials are piled into a conical pile shape, and the top of the obtained grain pile is dug into a funnel-shaped nest-shaped grain moistening water inlet with a downward depression, and the grain moistening water with a quality of 40%-60% of the grain raw material mass to be moistened is poured Enter the grain moistening water inlet, and then push the surrounding grain raw materials into t...

Embodiment 2

[0042] A grain moistening method in the brewing process of Maotai-flavor liquor, comprising the steps of:

[0043] (1) Prepare tools and grain raw materials; the grain raw materials use sorghum granules as the main brewing raw materials; every 1000kg-1100kg of grain raw materials is a pile;

[0044] (2) When the temperature of the moistening grain water is not lower than 95°C, start the first moistening of the grain; carry out the first moistening of the grain raw materials in batches. The grain moistening grain raw materials are piled into a conical pile shape, and the top of the obtained grain pile is dug into a funnel-shaped nest-shaped grain moistening water inlet with a downward depression, and the grain moistening water with a quality of 60%-80% of the grain raw material mass to be moistened is poured Enter the grain moistening water inlet, and then push the surrounding grain raw materials into the grain moistening water inlet and start to stir, and after stirring evenly...

Embodiment 3

[0048] A grain moistening method in the brewing process of Maotai-flavor liquor, comprising the steps of:

[0049] (1) Prepare tools and grain raw materials; the grain raw materials use sorghum granules as the main brewing raw materials; every 950kg-1000kg of grain raw materials is a pile;

[0050] (2) When the temperature of the grain moistening water is not lower than 95°C, the grain moistening starts for the first time; the grain raw materials are carried out in batches for the first moistening grain, and the quality of each batch of grain raw materials is 90-100kg, and one batch is taken to wait The grain moistening grain raw materials are piled into a cone-shaped pile, and the top of the obtained grain pile is dug into a funnel-shaped nest-shaped grain moistening water inlet with a downward depression, and the grain moistening water with a quality of 50%-70% of the grain raw material mass to be moistened is poured Enter the grain moistening water inlet, and then push the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com