Optical element reflectivity measurement instrument

A technology of optical components and reflectivity, which is applied in the field of instrument science, can solve the problems of measuring the size of optical components, failing to meet accuracy requirements, and unable to meet the requirements of online measurement of reflectivity of optical components, etc., and achieve the effect of simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

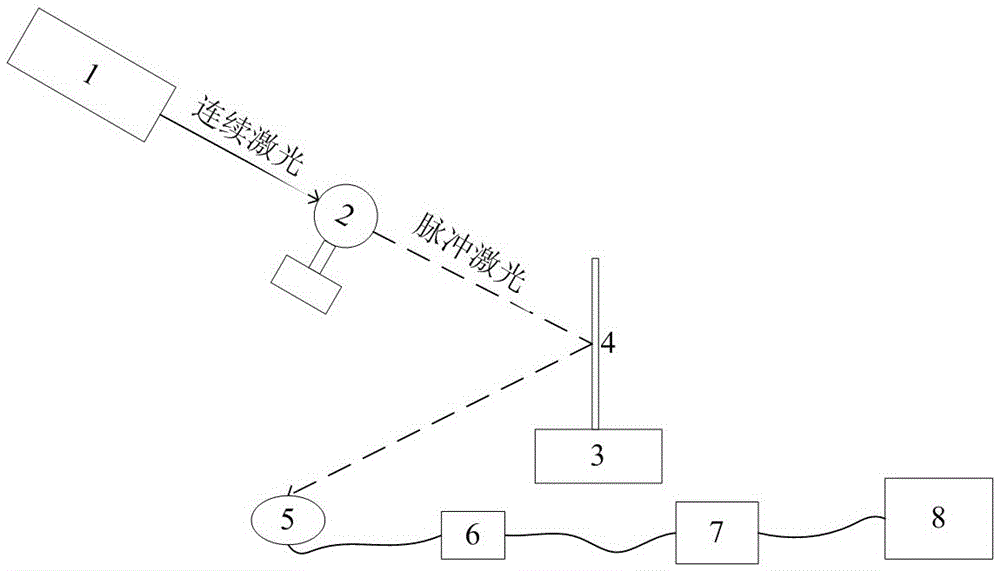

[0024] see figure 1 , the optical element reflectivity measuring instrument of the present invention comprises a laser 1, a light chopper 2, a sample loading platform 3, an optical standard sheet 4, a photodiode 5, a preamplifier 6, a lock-in amplifier 7 and a computer 8;

[0025] The laser light output by the laser 1 is modulated by the optical chopper 2 to become pulsed light, and the pulsed light is directly irradiated on the optical standard plate 4 or the optical element to be measured placed on the sample loading table 3, and the optical standard plate 4 or The reflected light reflected by the optical element to be tested is received by the photodiode 5 and converted into an electrical signal, and the electrical signal is respectively amplified by the preamplifier 6 and the lock-in amplifier 7 to output a DC voltage proportional to the intensity of the reflected light, and the DC voltage is obtained by the computer 8 receive and display.

[0026] The output laser of des...

Embodiment 2

[0031] Embodiment 2 is basically the same as Embodiment 1, the main difference being that an optical standard sheet 4 with a reflectance of 3.5% is replaced to measure the reflectance R of the optical element to be tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com