Minimal quantity lubrication grinding equipment coupled with electric card inner cooling grinding wheel and electrostatic technology

A micro-lubrication and electric card technology, which is applied in the field of grinding and processing, can solve the problems of wasting energy and low power utilization efficiency, and achieve the effects of reducing efficiency, improving processing efficiency and quality, and improving removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

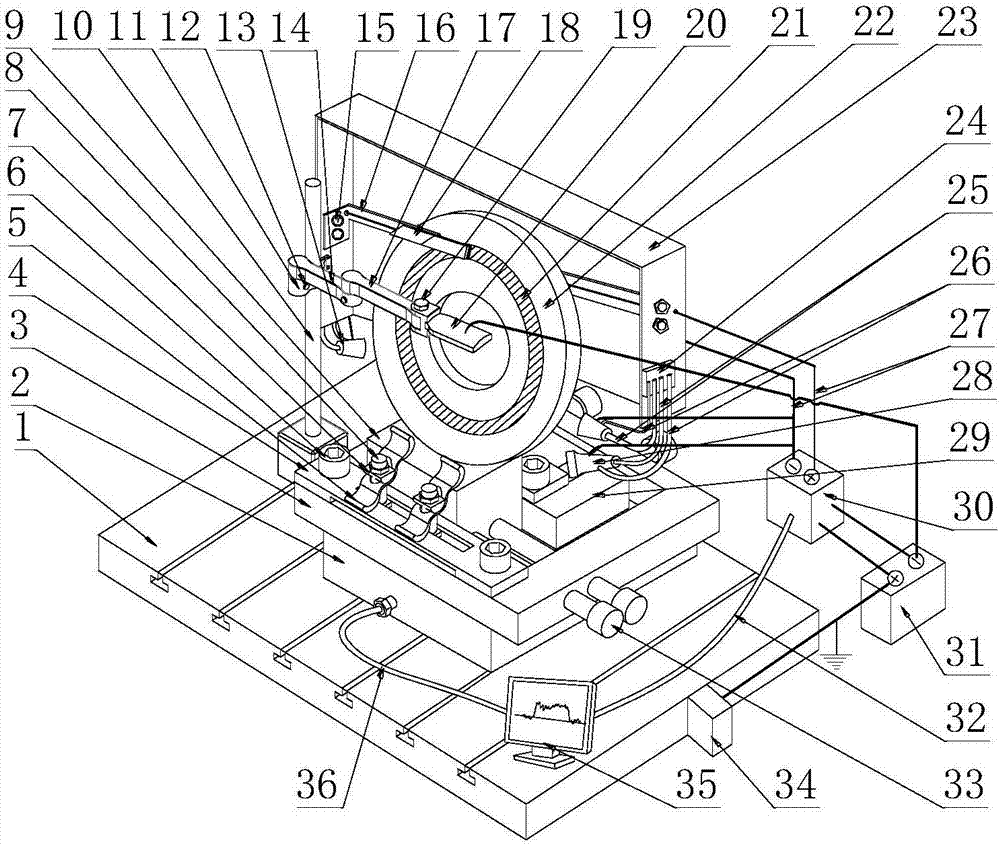

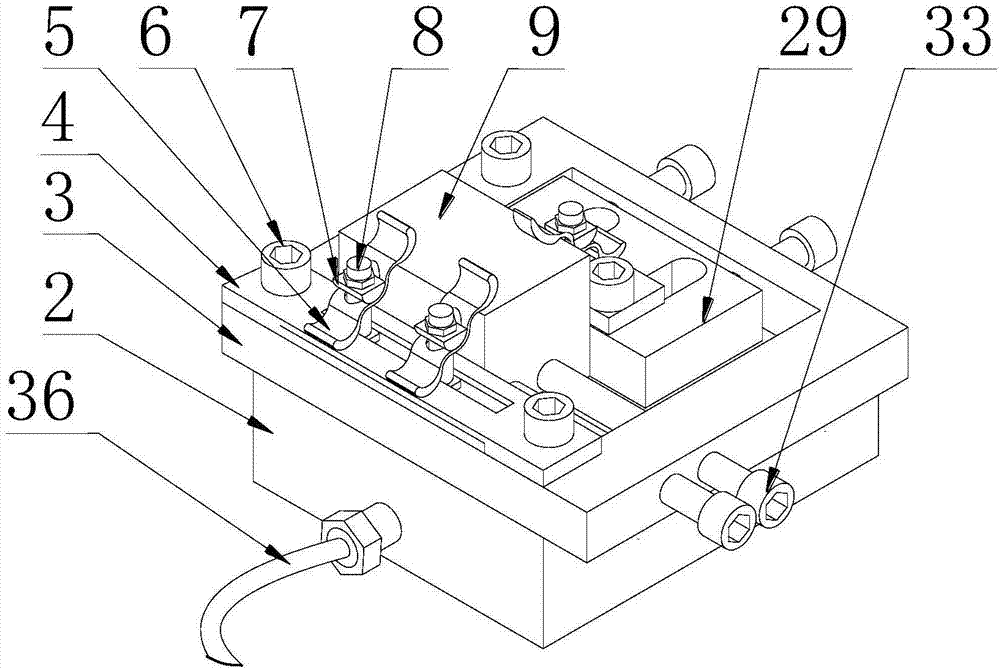

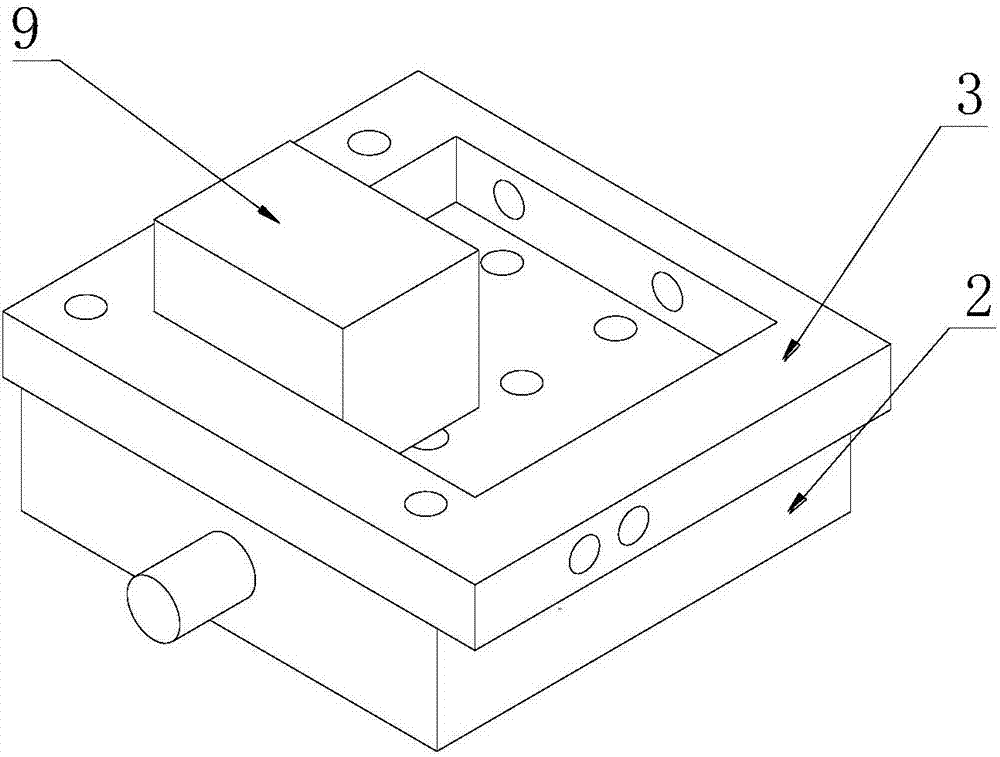

[0065] Such asfigure 1 As shown, the electric card grinding wheel 22 is to make the electric card material into nano or micron powder, which is added to the bond of the grinding wheel, and the amount of the added electric card material powder is not to affect the overall organization and structure of the grinding wheel. As a standard, the purpose is to maintain the overall performance of the electric card grinding wheel in the grinding process; it applies an external electric field through the brush 18 with Sn / Ag electrodes connected to the brush base 16; The power signal conversion device 30 is connected with the power generating device 31 to provide voltage; the brush base 16 is fixed on the grinding wheel cover 23 by the brush fixing bolt 15, wherein the positive pole and the negative pole of the electric brush 18 are respectively connected to the surfaces on both sides of the electric card grinding wheel 22 and The brush platinum sheet 21 contacts. The electrostatic atomiz...

Embodiment 2

[0082] The difference between this embodiment and the first embodiment is that the structure of the oil mist charging electrode is different.

[0083] Figure 12 It is an embodiment of the oil mist charging electrode 39, which is circular in shape and has a plurality of electrodes evenly distributed inside.

Embodiment 3

[0085] The difference between this embodiment and the first embodiment is that the structure of the oil mist charging electrode is different.

[0086] Figure 13 It is an embodiment of the oil mist charging electrode 39, which is elliptical in shape as a whole, and a plurality of electrodes are evenly distributed inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com