A wood planer for processing wood products

A wood planer and wood product technology, which is applied in the field of wood planers for wood product processing, can solve the problems of surface treatment smoothness and cleanliness of planed wood, time-consuming and manpower-consuming, complicated mechanical mechanisms, etc., and achieve the goal of planing Good wood effect, high degree of automation, and simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

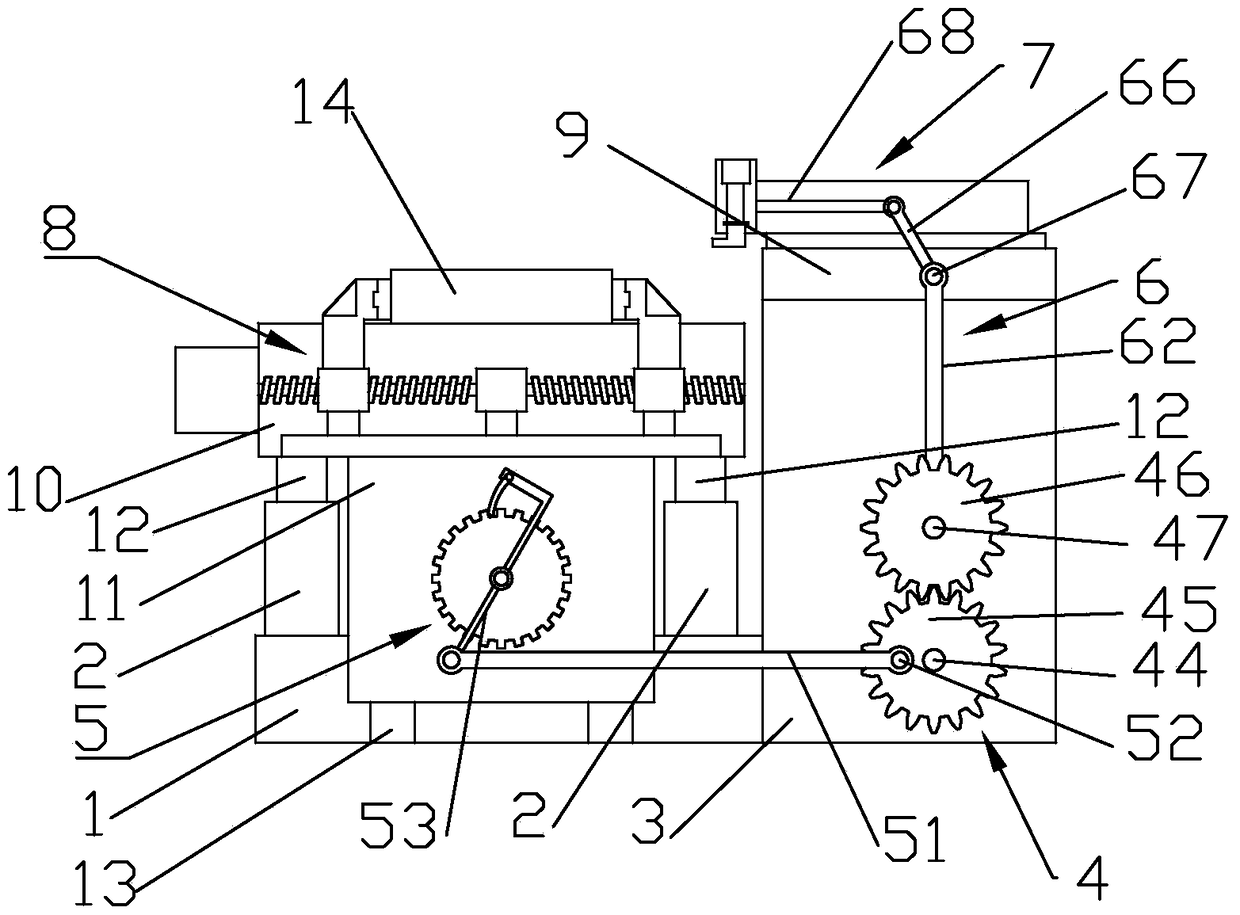

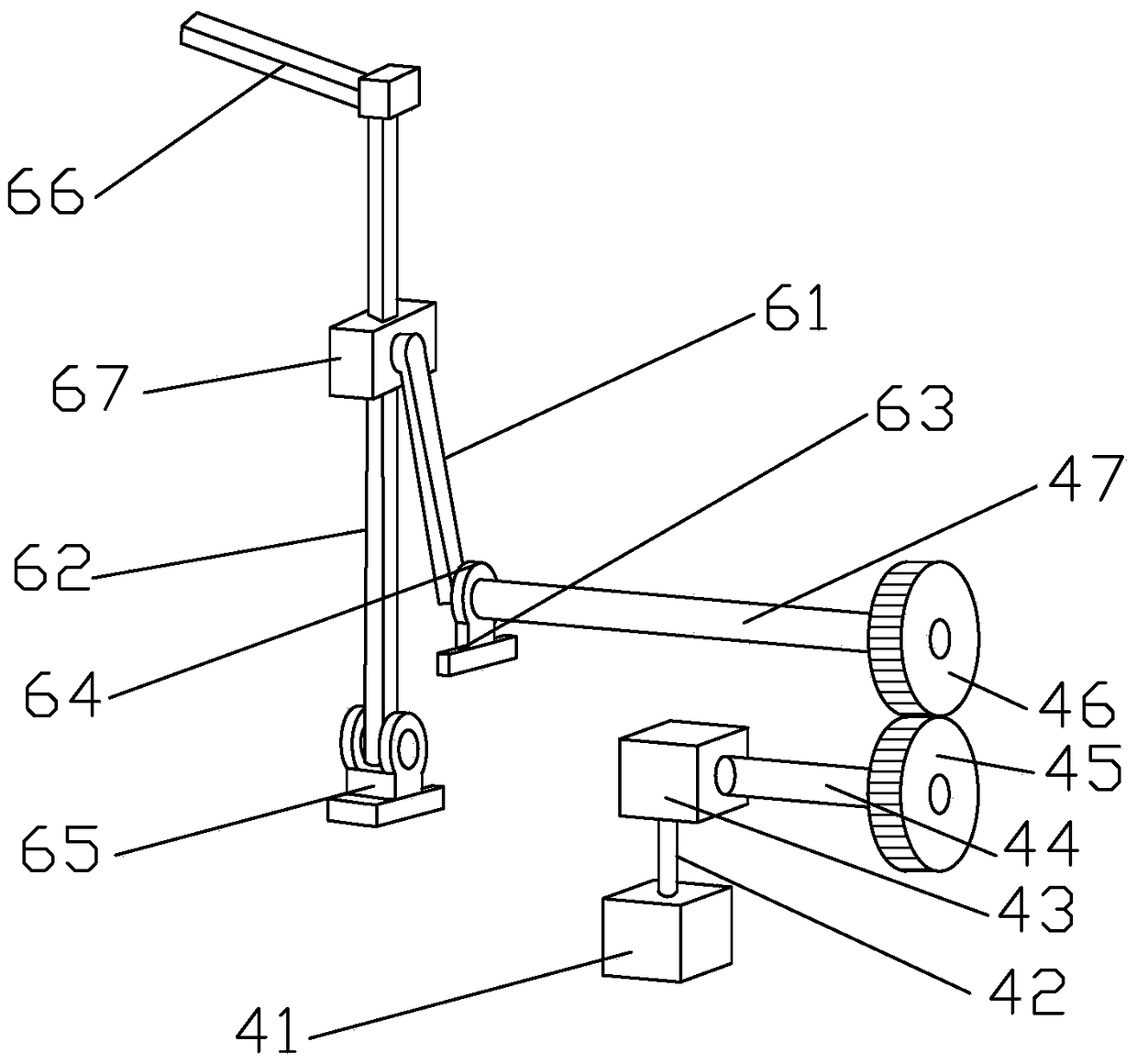

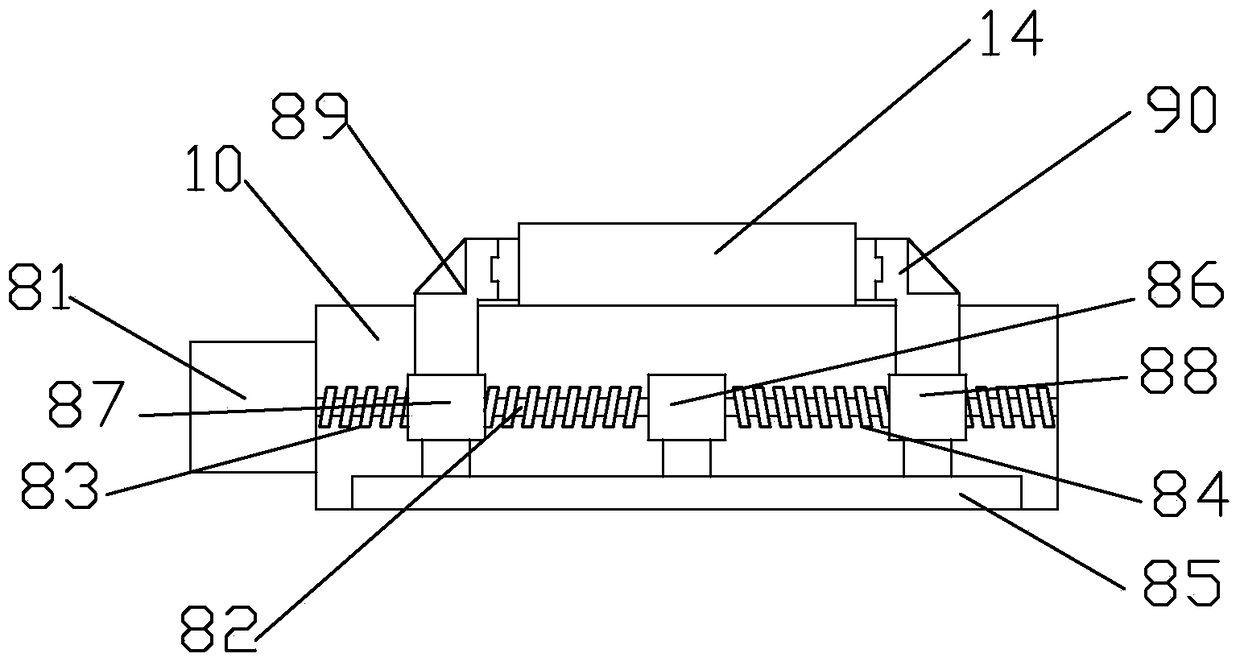

[0029] like Figure 1 to Figure 5 As shown, a wood planer for wood product processing includes a frame 1, a processing platform 2 and a knife seat 9, the processing platform 2 is horizontally installed on the frame 1, and the knife seat 9 is arranged on one side of the processing platform 2, and the knife Seat 9 is provided with planer wood component 7. The planer assembly 7 includes a planer head 71, a moving guide rail 72, a planer 73 and a planer lifting mechanism. The planer head 71 is installed on the moving guide rail 72, and the moving guide rail 72 is fixed on the tool holder 9. The planer lifting mechanism is installed on the planer. On the wood machine head 71, the planer lifting mechanism connects the planer 73, and the below of the knife seat 9 is provided with a transmission chamber 3. The planer lifting mechanism comprises a lifting cylinder 74 and a lifting piston rod 75, and the lifting cylinder 74 is installed on the planer head 71, and the lifting cylinder 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com