Method for machining internal thread of blind hole without tool withdrawal groove

An internal thread machining and thread machining technology, which is applied in the field of internal thread machining of blind holes without undercut grooves, can solve the problems of unstable quality, tool consumption, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

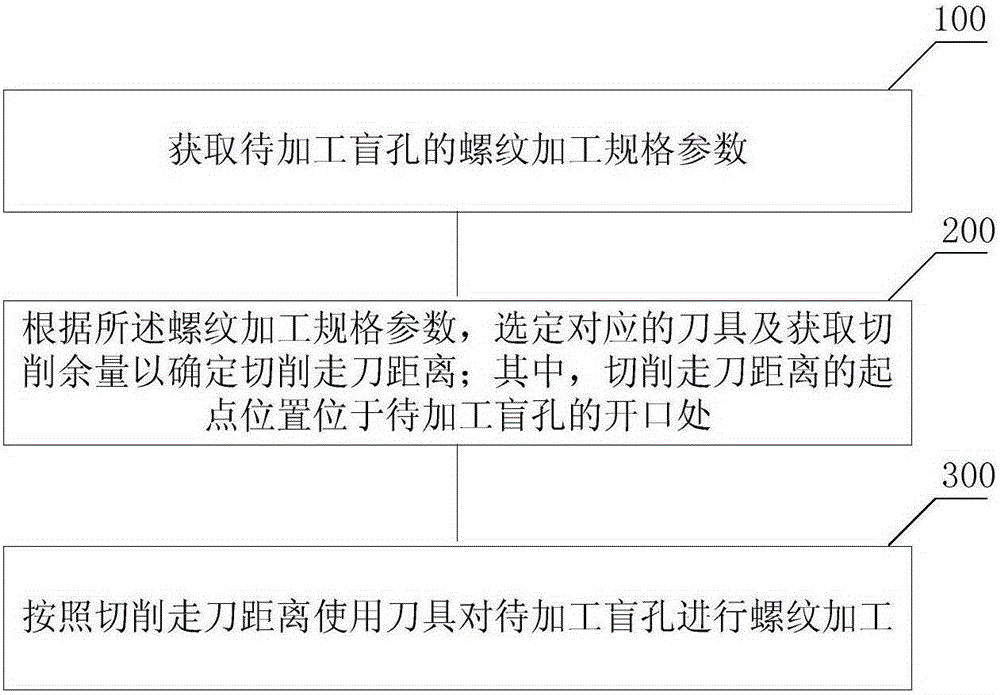

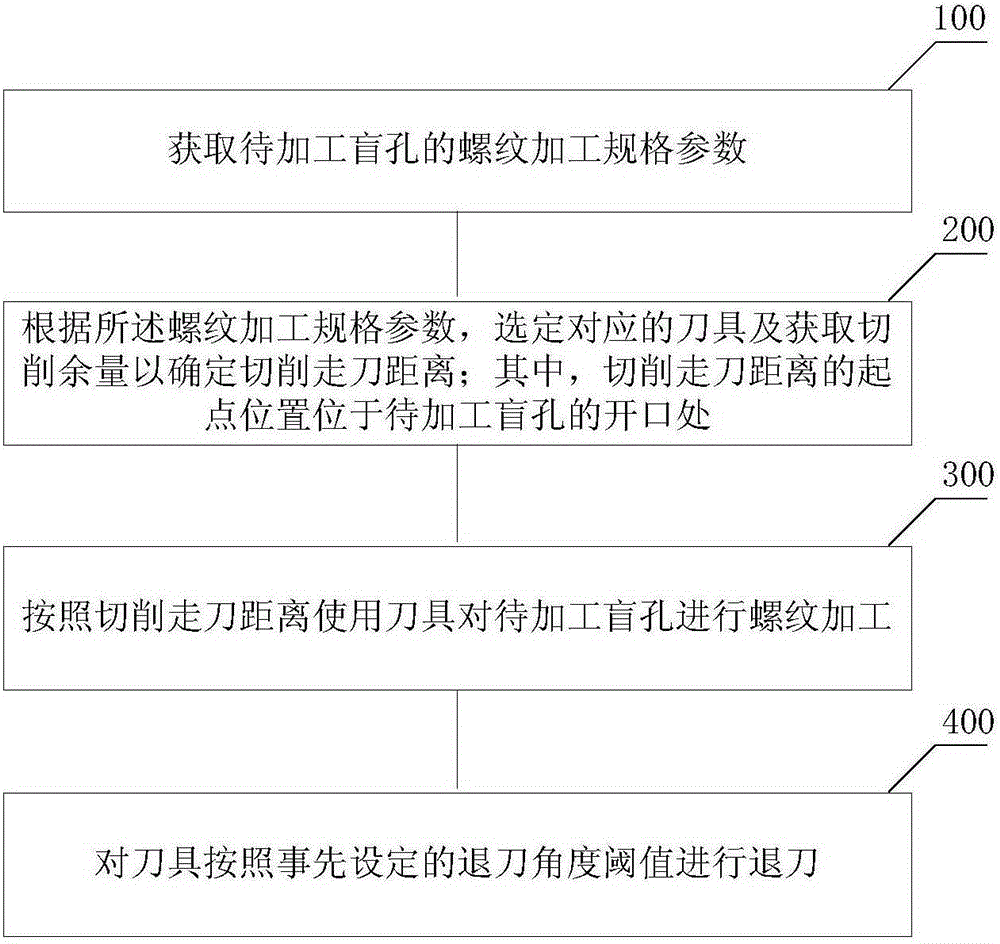

[0044] refer to figure 1 , a preferred embodiment of the present invention provides a method for machining an internal thread of a blind hole without an undercut, comprising the steps of:

[0045] Step S100 , obtaining the thread processing specification parameters of the blind hole to be processed.

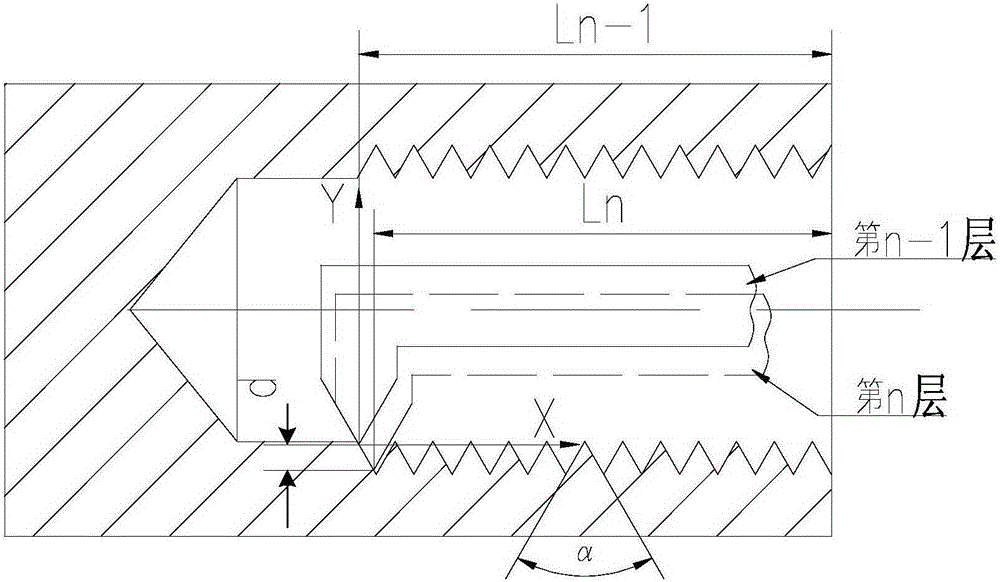

[0046] The CNC machine tool obtains the artificially input thread processing specification coefficient of the blind hole to be processed through the human-computer interaction interface. The thread processing specification parameters include the thread specification size, thread material, and thread profile angle. The size of the thread includes the nominal diameter of the thread, tooth depth, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com