Heat-resisting rubber composite material and preparing technology thereof

A composite material and heat-resistant rubber technology, which is applied in the preparation process of heat-resistant rubber composite materials and the field of heat-resistant rubber composite materials, can solve the problems of poor wear resistance, hardness and tear resistance, and low temperature, and achieve tear resistance Strong cracking, simple preparation process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

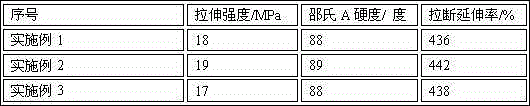

Embodiment 1

[0017] A heat-resistant rubber composite material, which is composed of the following raw materials in parts by weight: 86 parts of EPDM rubber, 15 parts of 1,3-butadiene, 5 parts of polybutylacrylate, 8 parts of zinc oxide, 3 parts of magnesium oxide, 1 part of stearic acid, 1 part of anti-aging agent, 30 parts of plasticizer, 3 parts of dicumyl peroxide, 50 parts of carbon black, 2 parts of hollow glass microspheres, and 0.5 part of sulfur.

[0018] In this embodiment, the anti-aging agent is specifically 2-thiobenzimidazole.

[0019] A preparation process for a heat-resistant rubber composite material, comprising the following steps:

[0020] (1) Mix EPDM rubber and 1,3-butadiene, keep stirring at 80°C for 5-9 minutes to obtain material a;

[0021] (2) Mix the above-mentioned material a with polybutyl acrylate, heat to 87°C, keep stirring for 7 minutes, and obtain material b;

[0022] (3) Put the above material b into a flat vulcanizing machine for vulcanization, and add ...

Embodiment 2

[0026] A heat-resistant rubber composite material, which is composed of the following raw materials in parts by weight: 88 parts of EPDM rubber, 20 parts of 1,3-butadiene, 7 parts of polybutylacrylate, 10 parts of zinc oxide, 4 parts of magnesium oxide, 2 parts of stearic acid, 3 parts of anti-aging agent, 32 parts of plasticizer, 5 parts of dicumyl peroxide, 60 parts of carbon black, 3 parts of hollow glass microspheres, and 1 part of sulfur.

[0027] In this embodiment, the anti-aging agent is specifically 2-thiobenzimidazole.

[0028] A preparation process for a heat-resistant rubber composite material, comprising the following steps:

[0029] (1) Mix EPDM rubber and 1,3-butadiene, heat and stir at 80°C for 8 minutes to obtain material a;

[0030] (2) Mix the above material a with polybutyl acrylate, heat to 90°C, keep stirring for 7 minutes to obtain material b;

[0031] (3) Put the above material b into a flat vulcanizing machine for vulcanization, and add zinc oxide, m...

Embodiment 3

[0035] A heat-resistant rubber composite material, which is composed of the following raw materials in parts by weight: 97 parts of EPDM rubber, 25 parts of 1,3-butadiene, 10 parts of polybutylacrylate, 15 parts of zinc oxide, 7 parts of magnesium oxide, 3 parts of stearic acid, 3 parts of anti-aging agent, 35 parts of plasticizer, 7 parts of dicumyl peroxide, 65 parts of carbon black, 5 parts of hollow glass microspheres, and 2 parts of sulfur.

[0036] In this embodiment, the anti-aging agent is specifically 2-thiobenzimidazole.

[0037] A preparation process for a heat-resistant rubber composite material, comprising the following steps:

[0038] (1) Mix EPDM rubber and 1,3-butadiene, keep stirring at 85°C for 5-9 minutes to obtain material a;

[0039] (2) Mix the above-mentioned material a with polybutyl acrylate, heat to 90°C, keep stirring for 8 minutes, and obtain material b;

[0040] (3) Put the above material b into a flat vulcanizing machine for vulcanization, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com