Liquid crystal display panel

A liquid crystal display panel, symmetry plane technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as abnormal display and uneven thickness of substrates, and achieve the effects of ensuring uniformity, reducing costs, and improving display performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

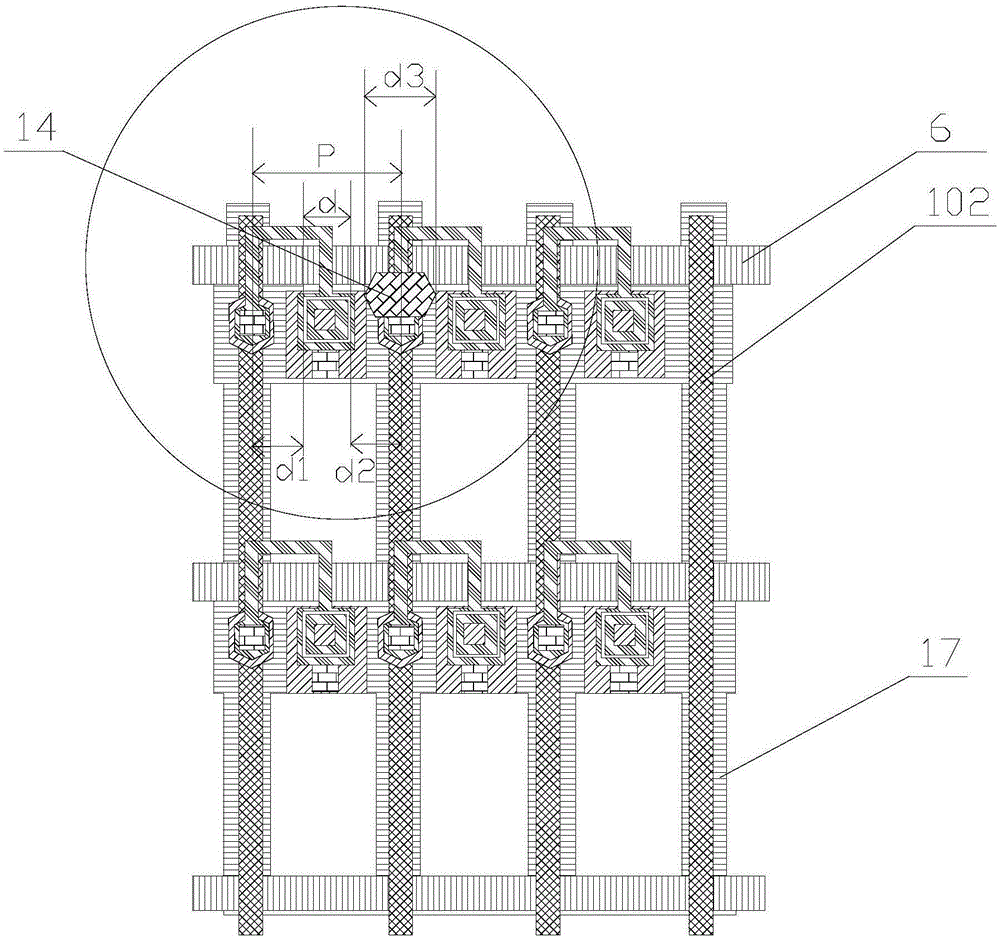

[0030] figure 2 A top view of a partial structure of a liquid crystal display panel in the prior art is shown. figure 2 It clearly shows that the array substrate of the liquid crystal display panel in the prior art includes a pixel unit 30 ( figure 2not marked). Each pixel unit 30 includes: a scanning line 6 extending along a first direction (ie, the left-right direction in the figure), a data line 102 extending along a second direction different from the first direction (ie, the up-down direction in the figure), and a selected pixel electrode (not shown in the figure); and a thin film transistor arranged between the data line 102 and the pixel electrode in a functionally connected manner. A black matrix 17 is provided at a position corresponding to the scan line 6 and the data line 102 for blocking light leakage. The pixel electrode may be disposed in an area surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com