Solid particles capable of releasing metasilicic acid and preparing method thereof

A technology of solid particles and metasilicate, applied in medical preparations containing active ingredients, pharmaceutical formulas, applications, etc., can solve the problems of not being able to provide metasilicate, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

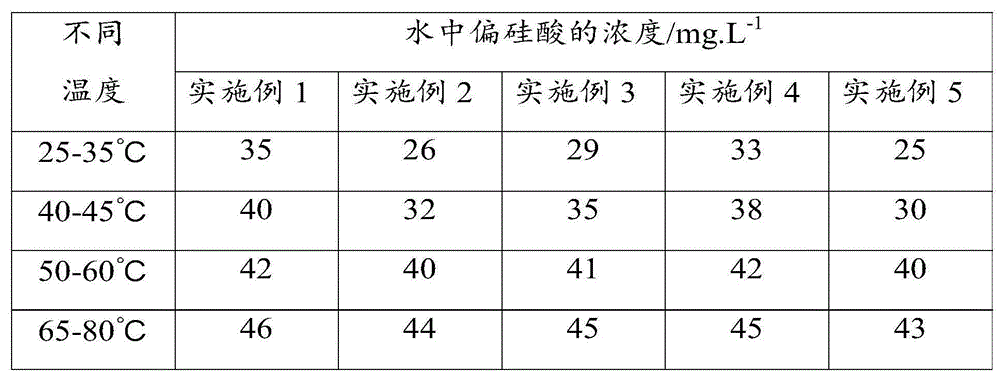

Examples

Embodiment 1

[0041] A solid particle that can release metasilicic acid, the inner layer is water-soluble silicon crystal, and the outer layer is medical stone powder. Wherein, the particle size of the water-soluble silicon crystal used in the inner layer is 8 mm, and the thickness of the outer layer of medical stone powder is 5 mm.

[0042] Its preparation method comprises the following steps:

[0043] Wet the water-soluble silicon crystals with water, immediately put them into the medical stone powder and stir continuously, so that the surface of the water-soluble silicon crystals is evenly adsorbed on the medical stone powder, and then take out the water-soluble silicon crystals with the medical stone powder adsorbed Air-dry in a cool place to get the first particles.

[0044] The medical stone powder is added to the first granular matter for granulation while spraying water mist, so that the medical stone powder is continuously adsorbed on the surface of the first granular matter, and th...

Embodiment 2

[0047] This embodiment provides a solid particle capable of releasing metasilicic acid, the inner layer is water-soluble silicon crystals, and the outer layer is medical stone powder. Wherein, the particle size of the water-soluble silicon crystal used in the inner layer is 4 mm, and the thickness of the outer layer of medical stone powder is 6 mm.

[0048] The preparation method that present embodiment adopts has done following improvement on the basis of embodiment 1:

[0049] Before calcining the second particles, the obtained second particles are air-dried in a cool environment. By air-drying this step, more than 70% of the water contained in the second particle can be removed, so as to avoid the medical stone powder caused by the uneven evaporation of water between the layers of medical stone powder adsorbed by the second particle during the calcination process. The outer layer is cracked.

[0050] After the second particles are air-dried, a three-stage calcination meth...

Embodiment 3

[0056] This embodiment provides a solid particle capable of releasing metasilicic acid, the inner layer is water-soluble silicon crystals, and the outer layer is medical stone powder. In addition, the particle size of the water-soluble silicon crystals in the inner layer is 5 mm, and the medical stone powder in the outer layer has a thickness of 5 mm.

[0057] Its preparation method has carried out following improvement on the basis of embodiment 1:

[0058] In the process of preparing the first particles, since the water-soluble silicon crystals are easily soluble in water and form metasilicate in water after being dissolved in water, it is equivalent to that the water-soluble silicon crystals can "release" metasilicate in water. Therefore, in this step, although adding water can wet the surface of the water-soluble silicon crystals and make the surface easy to be stained with medical stone powder, adding too much water will dissolve the water-soluble silicon crystals used, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com