Adjustable material fluidization machine

A fluidizer and adjustable technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of poor fluidization effect, inconvenient use, non-adjustment, etc., to achieve small footprint and improve work efficiency. Efficiency, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

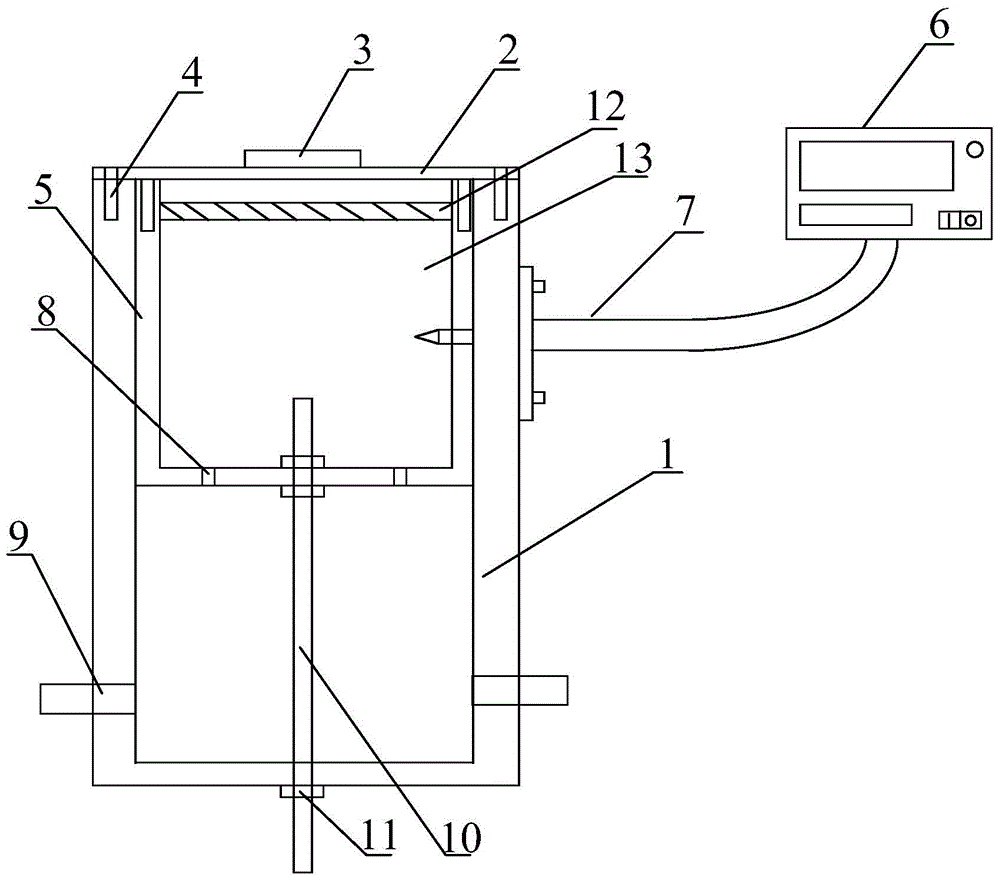

[0025] as attached figure 1 to attach image 3 shown

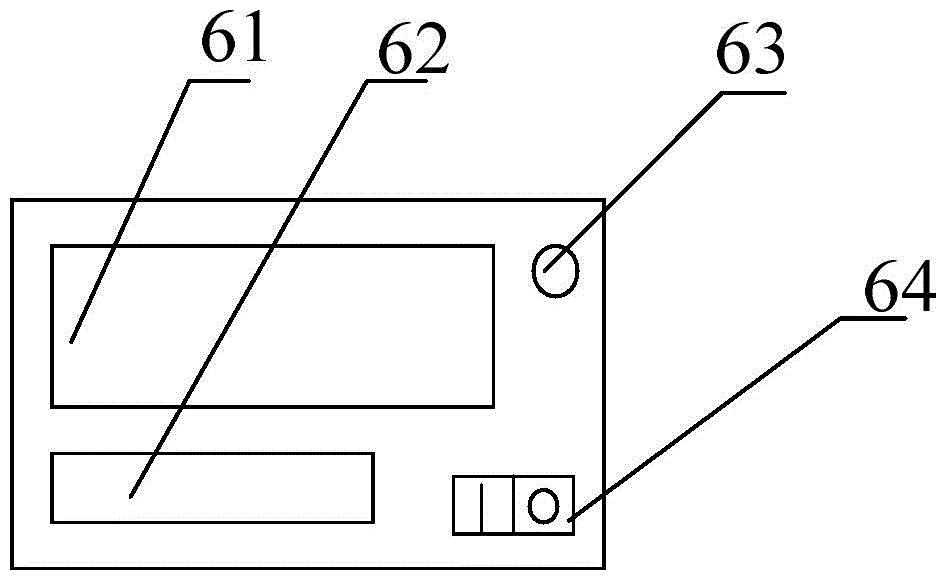

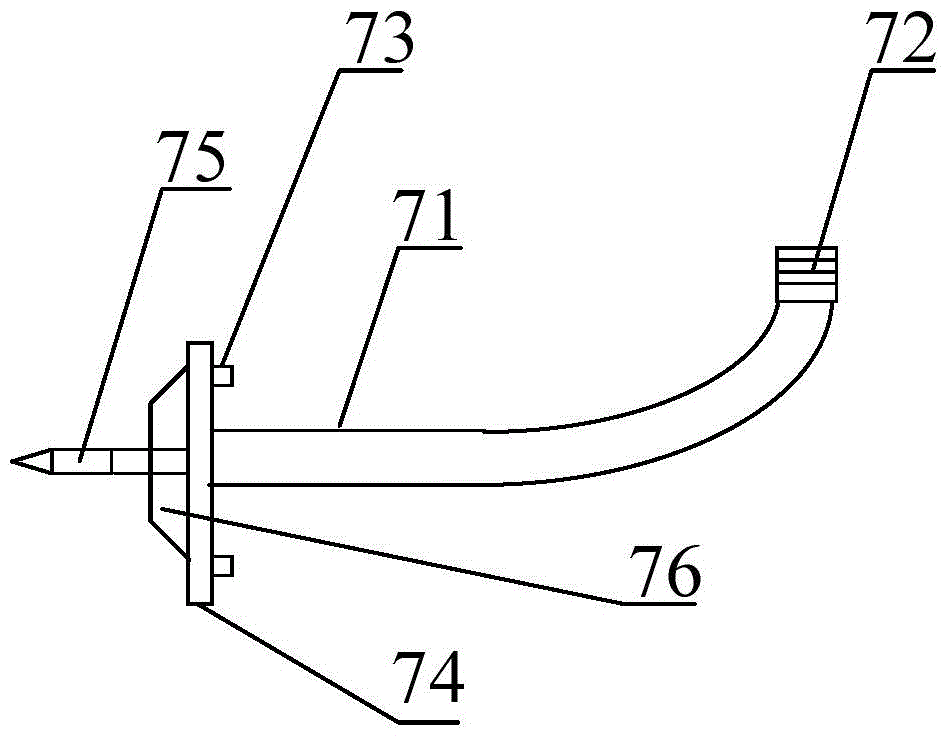

[0026] The invention provides an adjustable material fluidizer, which includes a cylinder barrel 1, a cover body 2, a handle 3, a fastening screw 4, a piston 5, an intelligent control device 6, a sensor connection structure 7, a vent hole 8, and an air intake pipe 9. Lead screw 10, lock nut 11, gasification plate 12 and gasification chamber 13, the cover 2 is installed on the upper part of the cylinder barrel 1 through fastening screws 4; the handle 3 is welded on the upper part of the cover 2 surface; the piston 5 is arranged at the lower part of the inner cover body 2 of the cylinder barrel 1; the gasification plate 12 is fixed inside the piston 5; the gasification plate 12 and the bottom of the piston 5 form a gasification chamber 13; The lower part of the gasification chamber 13 is provided with a vent hole 8; the screw 10 is installed at the central axis position of the bottom of the piston 5, and passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com