Polyaniline/iron oxide nano composite resistance-type material sensor, and preparation method thereof

An iron oxide nanometer and composite resistor technology, applied in the field of sensors, can solve the problems of difficult development and application of flexible optoelectronic devices, the sensitivity of gas sensors is not particularly high, and the combination of nanomaterials and substrates is not good enough, so as to promote bonding and promote charge transfer. , the effect of convenient steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the method of the present invention comprises the following steps:

[0033] 1. prepare the mixed solution of ferric chloride and polyvinyl butyral, i.e. spinning solution, the concentration of said ferric chloride is 50mg / mL, and the concentration of polyvinyl butyral is 30mg / mL; Ferric oxide can be any metal salt that can be dissolved in the spinning solution solvent and has good compatibility with spinning aids, including but not limited to ferric chloride and ferric nitrate; polyvinyl butyral can be any One or more spinnable polymers, including but not limited to polyvinyl butyral, polyvinylidene fluoride, polyvinyl chloride, polyvinyl alcohol;

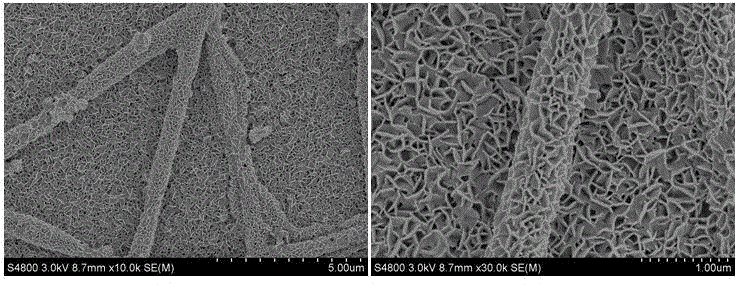

[0034]② Deposit the electrospinning solution in step ① in the form of nanofibers on the ceramic substrate under the electrospinning conditions of flow rate of 0.3mL / h; receiving distance of 15cm; spinning voltage of 8kV; receiving time of 3min; The ceramic substrate can be a flexible material or a ...

Embodiment 2

[0039] 1. prepare the mixed solution of ferric nitrate and polyvinyl butyral, i.e. spinning solution, the concentration of described ferric nitrate is 10mg / mL, and the concentration of polyvinyl butyral is 100mg / mL;

[0040] ②The electrospinning solution in step ① is deposited on the polyethylene terephthalic acid in the form of nanofibers under the electrospinning conditions of the flow rate of 0.1mL / h; the receiving distance of 5cm; the spinning voltage of 5kV; and the receiving time of 30min. on glycol ester substrates;

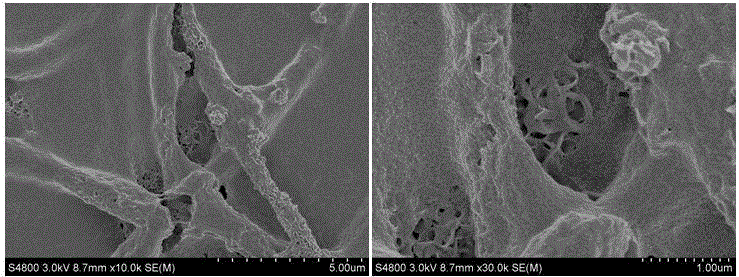

[0041] ③ drying the substrate deposited with nanofibers obtained in step ② and then hydrothermally treating it at 180° C. for 24 hours to obtain a substrate with a semiconductor iron oxide nanostructure grown in situ, and the preparation method;

[0042] ④ Dip-coating a layer of polyaniline on the substrate prepared in step ③ with the semiconductor iron oxide nanostructure to prepare a gas sensor.

[0043] The resulting method has a low resistance of less...

Embodiment 3

[0045] 1. prepare the mixed solution of ferric nitrate and polyvinyl chloride, i.e. spinning solution, the concentration of described ferric nitrate is 300mg / mL, and the concentration of polyvinyl chloride is 40mg / mL;

[0046] ② Deposit the electrospinning solution in step ① in the form of nanofibers on the polytetrafluoroethylene substrate under the electrospinning conditions of flow rate 1mL / h; receiving distance 30cm; spinning voltage 30kV; receiving time 30min superior;

[0047] ③ drying the substrate deposited with nanofibers obtained in step ② and then hydrothermally treating it at 120° C. for 6 hours to obtain a substrate with semiconductor iron oxide nanostructures grown in situ, and the preparation method;

[0048] ④ Dip-coating a layer of polyaniline on the substrate prepared in step ③ with the semiconductor iron oxide nanostructure to prepare a gas sensor.

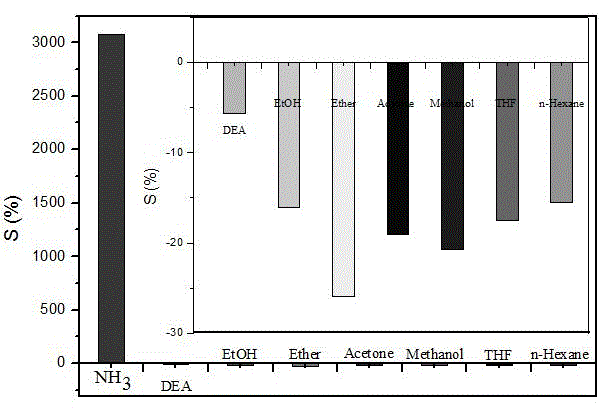

[0049] The resulting method has a low impedance of less than 200 kΩ at low concentrations (≤10 ppm), a good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Interdigital gap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com