Grain threshing machine capable of conducting continuous operation

A continuous operation, thresher technology, applied in threshing equipment, agricultural machinery and tools, agriculture, etc., can solve problems such as temperature rise, dust increase, grain damage, etc., and achieve the effect of heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

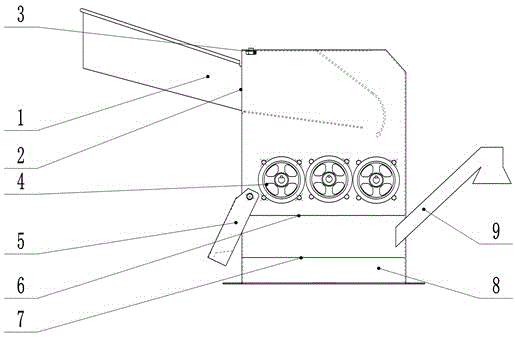

[0016] Such as figure 1 Shown, a kind of grain threshing machine of continuous operation is characterized in that: comprise threshing machine housing, be arranged on the feeding hopper 1 outside the threshing machine housing, be arranged on the threshing device and the screening device in the threshing machine housing; The bucket 1 is an inclined bucket, and a weighing gate 2 is set at the joint between the feeding hopper 1 and the shell of the threshing machine, and a weighing controller 3 is set on the weighing gate 2; the threshing device includes three threshing rollers arranged in parallel. 4. The threshing roller 4 is cylindrical, with a rotating shaft connected in the middle, and the rotating shaft is connected to the output motor. The circumferential surface of the threshing roller 4 is evenly distributed with triangular spikes; the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com