Smoke eliminator for heating furnace cooking bench

A technology for a heating furnace and a smoke remover, which is applied in the field of smoke removal equipment, can solve the problems of increasing equipment cost and equipment installation labor cost, and achieves the effect of reducing equipment cost and labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below by specific embodiments:

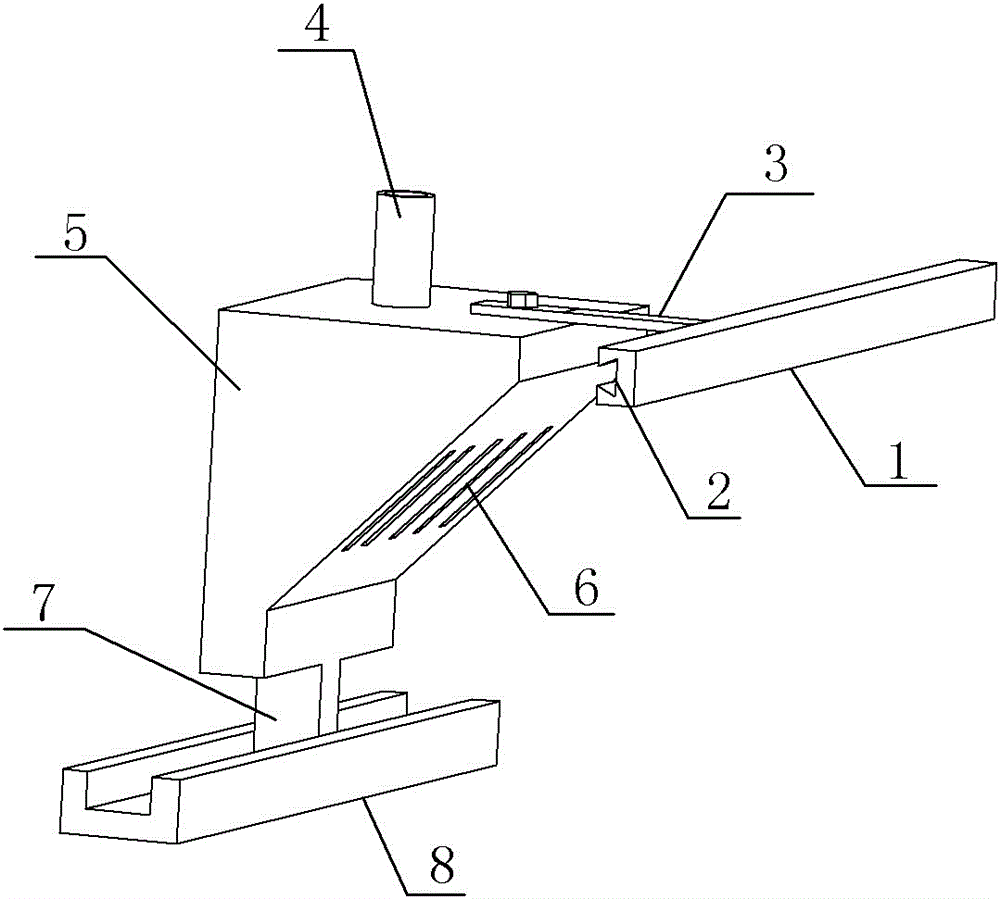

[0012] The reference signs in the accompanying drawings include: upper guide rail 1 , dovetail groove 2 , connecting rod 3 , smoke pipe 4 , smoke removal hood 5 , air hole 6 , support foot 7 , and guide groove 8 .

[0013] The embodiment is basically as shown in the attached drawings: the smoke eliminator for the heating cooktop includes an upper guide rail 1, a smoke removal hood 5 and a lower guide rail.

[0014] The upper guide rail 1 is fixed on the side wall of the heating cooktop by screws, the guide surface of the upper guide rail 1 is provided with a dovetail groove 2, and the upper end of the smoke removing hood 5 is horizontally fixed with a connecting rod 3 by bolts, and the end of the connecting rod 3 (also The free end) extends into the dovetail groove 2 and is slidingly matched with the upper guide rail 1 .

[0015] The inside of the smoke removing hood 5 is a smoke coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com