Preparation and application of cobalt ferrite-quasi-graphene carbon nano-composite magnetic adsorption material

A magnetic adsorption material, graphene carbon technology, applied in the direction of adsorption of water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of low industrial utilization, difficult recycling, reuse, and unsatisfactory adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Grapefruit peel pretreatment: collect waste grapefruit peels from surrounding fruit markets, soak them in distilled water to remove surface impurities, cut them into small pieces of about 1 cm × 5 cm, dry them in a drying oven at 60°C to constant weight, and mark For PP, put it in a sealed bag for later use;

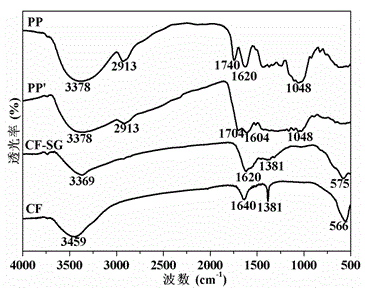

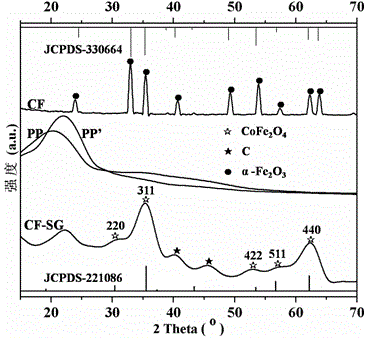

[0048] (2) Preparation of composite materials: 0.8080 g Fe(NO 3 ) 3 9H 2 O, 0.2910 g Co(NO 3 ) 2 ·6H 2 O(Fe 3+ 、Co 2+ The mass ratio of the substance is 2:1), after being dissolved in 48 mL deionized water, 0.7500 g PP (mass of pomelo peel and Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 ·6H 2 The total mass ratio of O is 0.68: 1) immersed in the solution, transferred to a polytetrafluoroethylene reactor, and reacted at 200 °C for 10 h; centrifuged, washed, and dried to obtain a composite material, labeled as CF-SG-1;

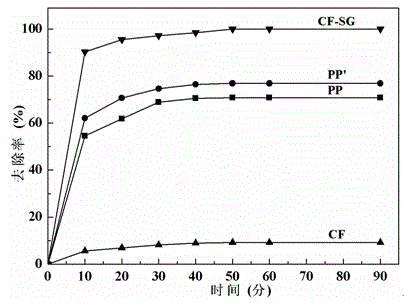

[0049] (3) Properties of the composite material: the magnetization is 16.1 emu / g; the adsorption rate of methylene blue is 89.1%.

Embodiment 2

[0051] (1) grapefruit peel pretreatment: with embodiment 1;

[0052] (2) Preparation of composite materials: the amount of grapefruit peel was 1.2500 g (the mass of grapefruit peel and Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 ·6H 2 O total mass ratio is 1.14: 1), others are the same as in Example 1; the composite material obtained is marked as CF-SG-2;

[0053] (3) Properties of the composite material CF-SG-2: the magnetization is 14.0 emu / g; the adsorption rate of methylene blue is 98.8%.

Embodiment 3

[0055] (1) grapefruit peel pretreatment: with embodiment 1;

[0056] (2) Preparation of composite materials: the amount of grapefruit peel is 2.5000 g (the mass of grapefruit peel and Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 ·6H 2 O total mass ratio is 2.28: 1), others are the same as embodiment 1; The composite material obtained is marked as CF-SG-3;

[0057] (3) Properties of the composite material CF-SG-3: the magnetization is 8.99 emu / g; the adsorption rate of methylene blue is 78.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetization | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com