A horizontal guide deviation correction system for jacking up bridges and culverts passing under existing lines

An existing line and jacking technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long time-consuming static correction and damage to the bridge body, avoid manual measurement and calculation, improve observation accuracy, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A horizontal guiding deviation correction system proposed by the present invention for underpassing existing line bridges and culverts will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the drawings are all in very simplified form and inexact proportions, and are only used to facilitate and clearly illustrate the purpose of the present invention.

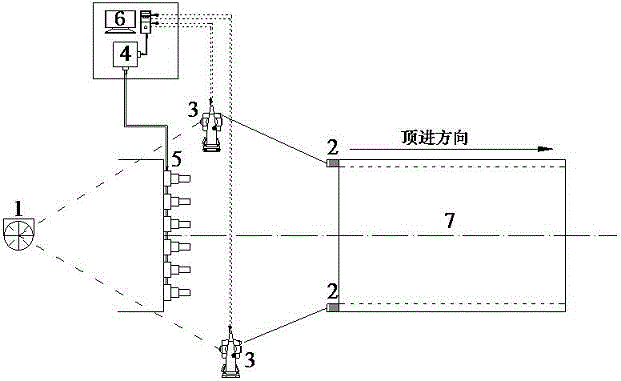

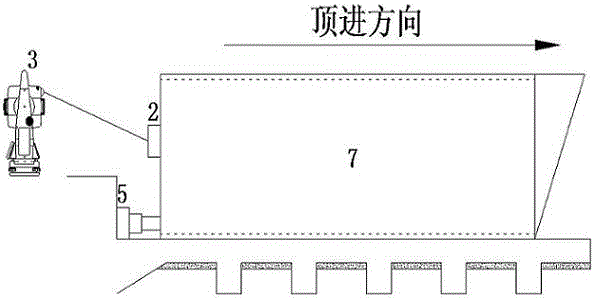

[0028] like figure 1 As shown, the present invention proposes a horizontal guiding and correcting system for jacking up bridges and culverts passing through existing lines. Push system 5 and main control computer 6.

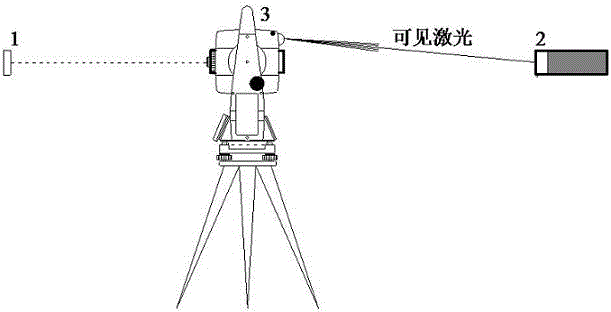

[0029] In the present invention, the backsight point is set at 10 m behind the jacking, and the backsight prism 1 is installed, and the backsight point is at a certain distance from the back so as not to affect the observation result due to the deformation of the back. A laser target unit 2 is respectively installed in the middle of both side walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com