Variable speed winding planetary reducer

A technology of planetary reducer and planetary carrier, which is applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of inability to adjust the speed ratio, endanger the personal safety of the device, and malfunction of the mechanism, etc., and achieve compact structure and processing Convenience and the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

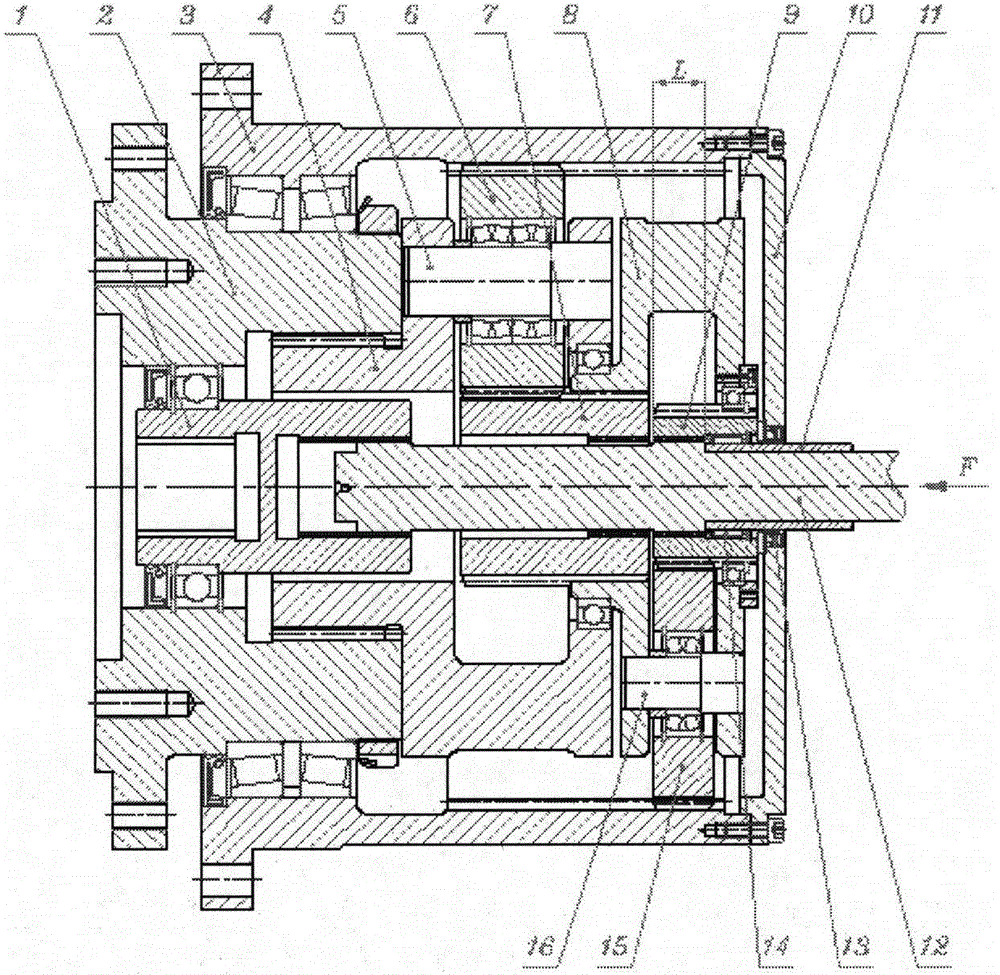

[0013] Such as Figure 1-2 As shown, a variable speed hoisting planetary reducer includes input shaft 1, fixed flange 2, output ring gear 3, primary planetary carrier 4, primary planetary gear 6, primary sun gear 7, and secondary planetary carrier 8 , secondary sun gear 9, secondary planetary gear 15 and end cover 10, one side of the primary planetary gear 6 meshes with the primary sun gear 7, the other side of the primary planetary gear 6 meshes with the output ring gear 3, and the primary planetary gear The wheel 6 is fixed on the first-stage planetary carrier 4 through the first-stage pin shaft 5, and the first-stage planetary carrier 4 cooperates with the fixed flange 2 and is installed on the fixed bracket of the equipment; one side of the second-stage planetary wheel 15 is connected with the second-stage sun gear 9 meshing, the other side of the secondary planetary gear 15 meshes with the output ring gear 3, the secondary planetary gear 15 is fixed on the secondary plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com