A chemical mechanical grinding time setting method based on clustering and multi-task learning

A multi-task learning and chemical-mechanical technology, applied in the fields of automatic control, information technology and advanced manufacturing, can solve the problem of less data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

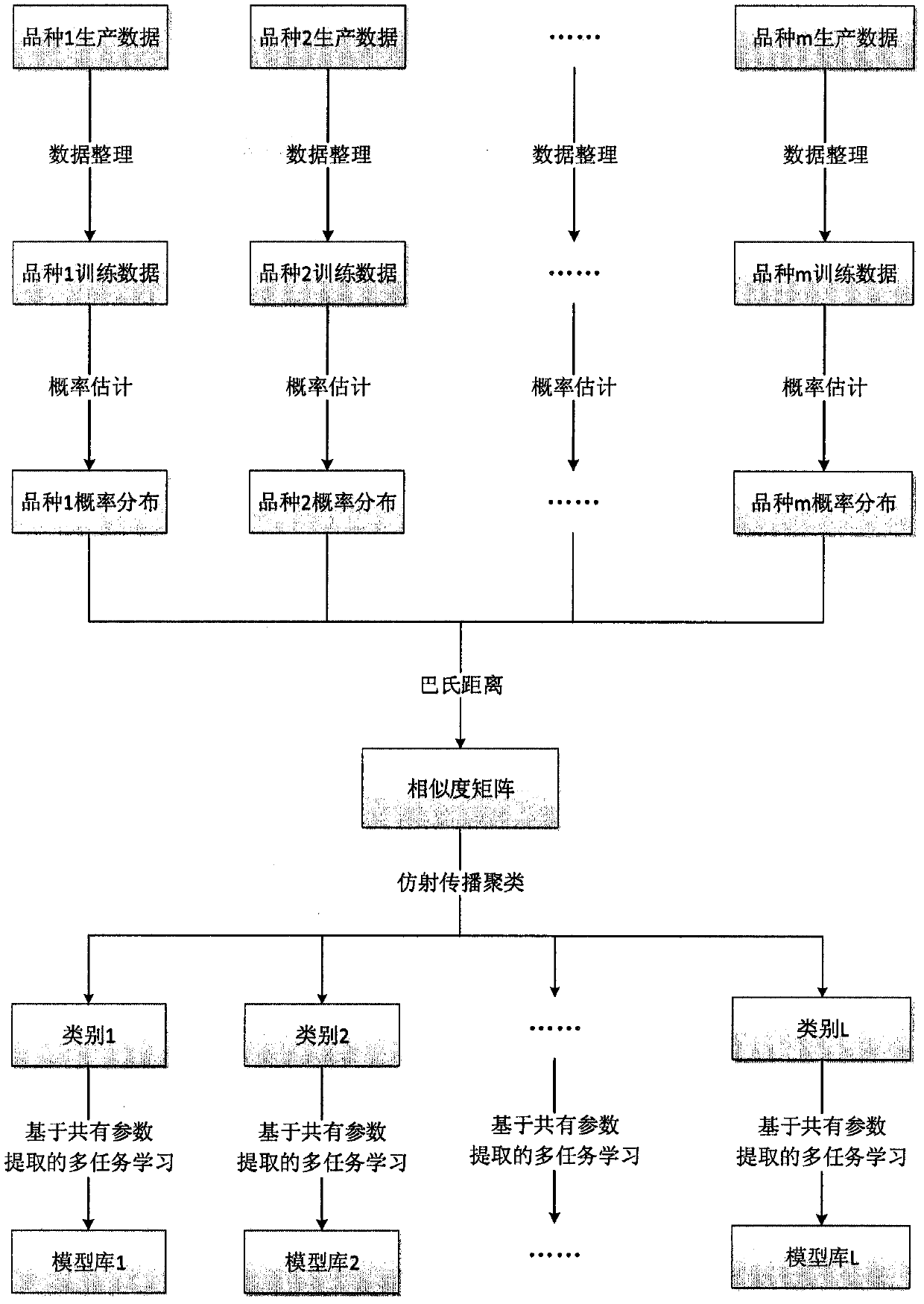

Method used

Image

Examples

Embodiment Construction

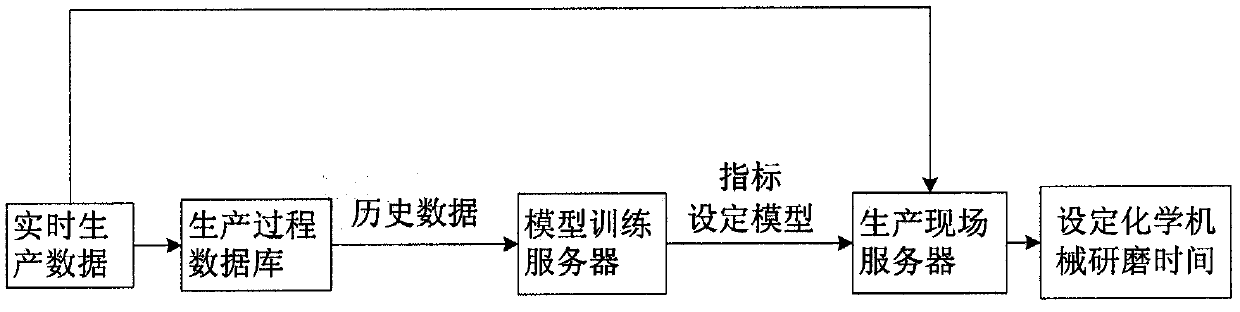

[0052] The present invention proposes a chemical mechanical grinding time setting method based on clustering and multi-task learning. Its main advantage is that it can be used in multi-variety mixed production, and can improve production efficiency compared with manual setting. In the actual application process, if a new production batch arrives, the grinding time can be calculated according to its variety and processing layer type and other batch information. The learning algorithm based on clustering and multi-task of the present invention depends on related hardware equipment, including: data acquisition system, algorithm server and user client, and is realized by intelligent optimization software. The present invention proposes method flow chart as figure 2 shown.

[0053] Step (1): Data Acquisition

[0054] The collected production information includes lot product variety, processing level, material removal rate, incoming sheet thickness, leading sheet output thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com