Texture pretreatment liquid for diamond wire cutting polycrystalline silicon wafer, texturing pretreatment method, texturing pretreatment silicon wafer and application thereof

A diamond wire cutting, polycrystalline silicon wafer technology, applied in the direction of post-processing, post-processing details, chemical instruments and methods, etc., can solve problems such as low-reflectivity suede, achieve simple proportioning, simple texturing pretreatment method, and easy operation. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A kind of texturing pretreatment method of diamond wire cut polysilicon chip, comprises the steps:

[0080] (1) Prepare the first and second treatment solutions:

[0081] Mix hydrofluoric acid, hydrogen peroxide, silver nitrate and water to obtain the first treatment liquid, wherein the molar concentration of silver ions is 15 μmol / L, the volume ratio of hydrofluoric acid, hydrogen peroxide and water is 3:13:8, and the hydrofluoric acid The mass concentration of acid is 49%, and the mass concentration of hydrogen peroxide is 30%;

[0082] Prepare nitric acid and strong alkali solutions respectively to obtain the second treatment solution A, wherein the mass concentration of nitric acid is 10%, and the mass concentration of strong alkali is 5%;

[0083] (2) Pretreatment:

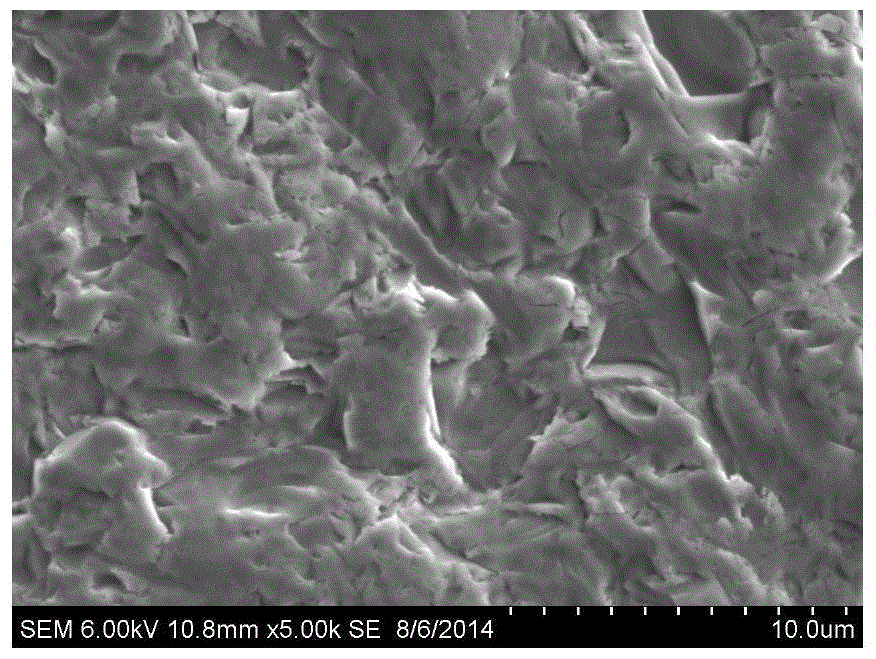

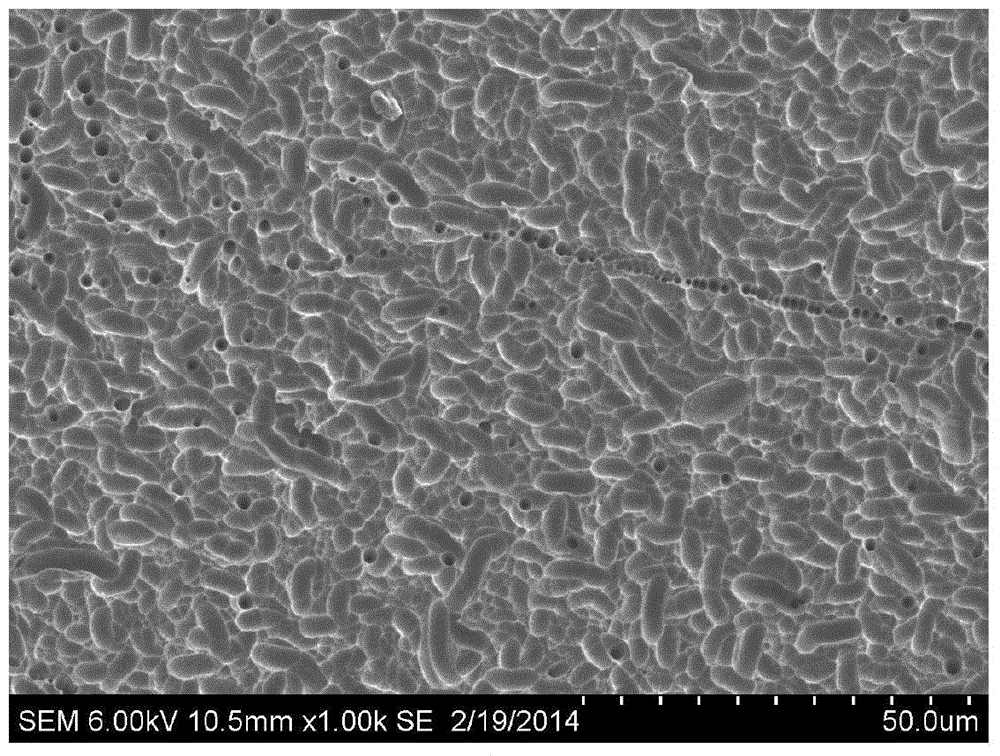

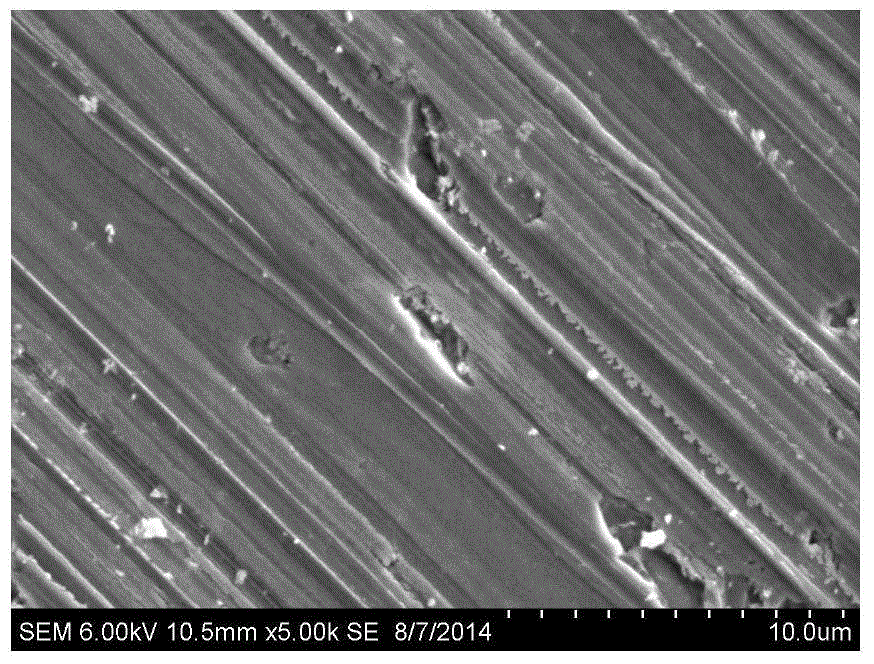

[0084] a. Preparation of porous silicon structure:

[0085] Take the polycrystalline silicon wafer cut by diamond wire, wash it with a dilute HF solution with a concentration of 10%, remove the oil ...

Embodiment 2

[0099] A kind of texturing pretreatment method of diamond wire cut polysilicon chip, comprises the steps:

[0100] (1) Prepare the first and second treatment solutions:

[0101] Mix hydrofluoric acid, hydrogen peroxide, silver nitrate and water to obtain the first treatment liquid, wherein the molar concentration of silver ions is 15 μmol / L, the volume ratio of hydrofluoric acid, hydrogen peroxide and water is 3:13:8, and the hydrofluoric acid The mass concentration of acid is 49%, and the mass concentration of hydrogen peroxide is 30%;

[0102] Mix nitric acid, hydrofluoric acid and water to obtain the second treatment liquid B, wherein the volume ratio of nitric acid, hydrofluoric acid and water is 30:1:100;

[0103] (2) Pretreatment:

[0104] a. Preparation of porous silicon structure:

[0105] Take the polycrystalline silicon wafer cut by diamond wire, wash it with a dilute HF solution with a concentration of 10%, remove the oil stain and oxide layer on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com