Multi-layer aluminum-plastic compound flame-retardant thermal-insulation material

A technology of flame retardant thermal insulation and thermal insulation materials, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc. Mechanical strength, safe and convenient construction, the effect of improving tensile strength and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

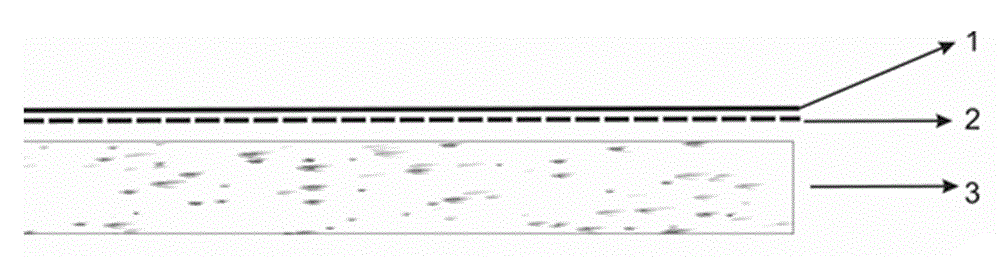

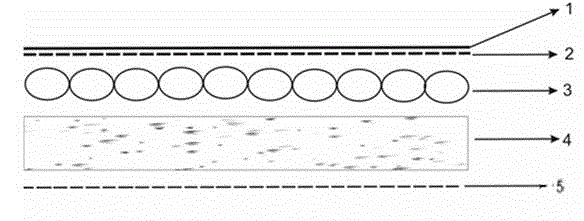

[0022] Embodiment 1. A multi-layer aluminum-plastic composite flame-retardant thermal insulation material, which includes an outer anti-glare aluminum foil layer 1 connected in sequence, a first flame-retardant polyethylene braid layer 2, a gas-retardant bead layer 3, a flame-retardant Foaming material layer 4, second flame-retardant polyethylene braiding layer 5. Among them, the outer anti-glare aluminum foil layer, the first flame-retardant woven cloth layer, the gas-resistant bead layer, the flame-retardant foam material layer and the second flame-resistant woven cloth layer are all connected into one body through the adhesive layer in turn; the outer The anti-glare aluminum foil layer is a layer of light-colored polyethylene film layer compounded on the surface of the outer aluminum foil layer through the coating process; the adhesive layer is a polyethylene adhesive layer; the flame-retardant foam material layer is a flame-retardant chemical cross-linked Linked polyethyle...

Embodiment 2

[0023] Embodiment 2, a multi-layer aluminum-plastic composite flame-retardant thermal insulation material, which includes an outer anti-glare aluminum foil layer 1 connected in sequence, a first flame-retardant polyethylene braid layer 2, a gas-retardant bead layer 3, a flame-retardant Foaming material layer 4, second flame-retardant polyethylene braiding layer 5. Among them, the outer anti-glare aluminum foil layer, the first flame-retardant woven cloth layer, the gas-resistant bead layer, the flame-retardant foam material layer and the second flame-resistant woven cloth layer are all connected into one body through the adhesive layer in turn; the outer The anti-glare aluminum foil layer is a layer of light-colored polyethylene film layer compounded on the surface of the outer aluminum foil layer through the coating process; the adhesive layer is a polyethylene adhesive layer; the flame-retardant foam material layer is a flame-retardant chemical cross-linked Linked polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com