Rapid safe construction method and device for bag poured airtight wall and anti-explosion wall

An airtight wall and explosion-proof wall technology, which is applied in mining installations, earth-moving drilling, mining equipment, etc., can solve problems such as difficulty in ensuring air tightness, injury and loss of personnel outside the airtightness, saving time, reducing operation risks, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] Since the fast and safe construction method of the present invention preferably uses the fast and safe construction device of the present invention, the structure of the fast and safe construction device of the present invention will be described in detail below:

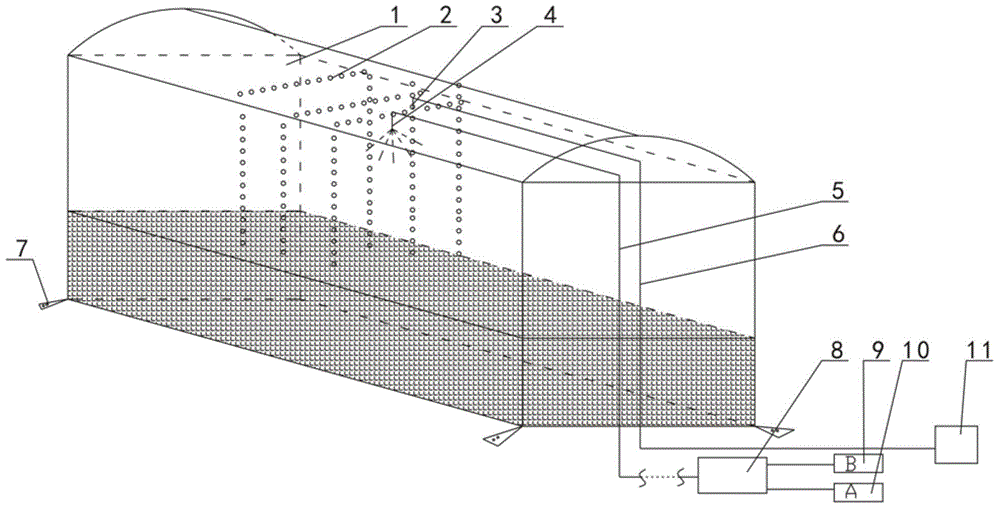

[0031] Such as figure 1 As shown, the rapid and safe construction device of the capsule perfusion type airtight wall and explosion-proof wall of the present invention includes a flame-retardant capsule 1, a slurry delivery pipe 5, a slurry mixing and delivery device 8, an air pipe 6 and a compressed air source 11, and the resistance The flame retardant capsule body 1 is made of flame retardant material such as cloth with flame retardant function. The density of the flame retardant material is limited to the fact that the liquid mixed slurry basically does not leak. The four corners of the bottom of the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com