Compound granule for direct broadcasting and application

A granule, direct technology, applied in the field of pesticides, can solve the problems of increased workload, high labor intensity, and short duration of efficacy, and achieve the effect of reducing pollution and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

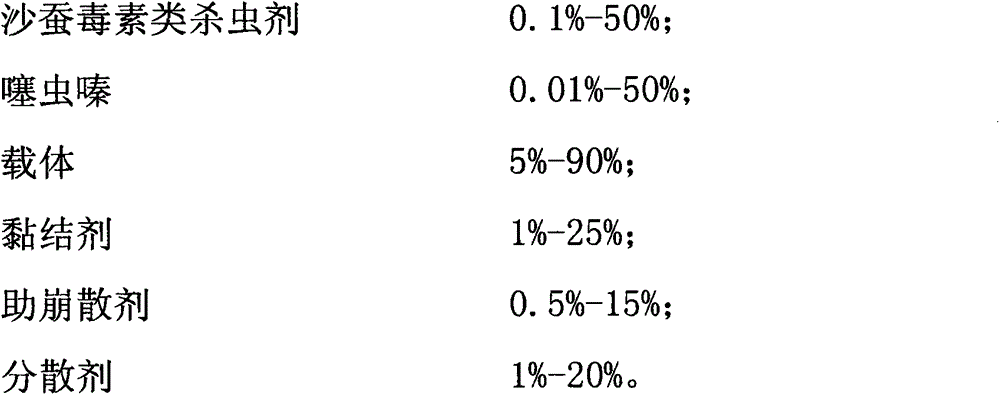

Method used

Image

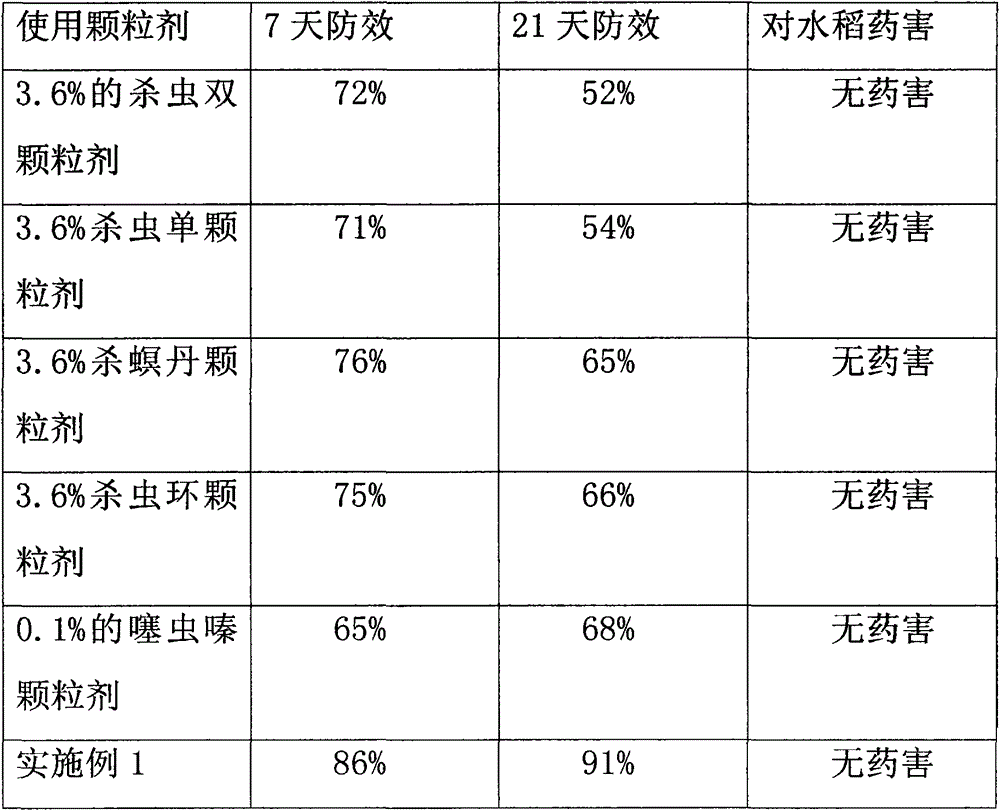

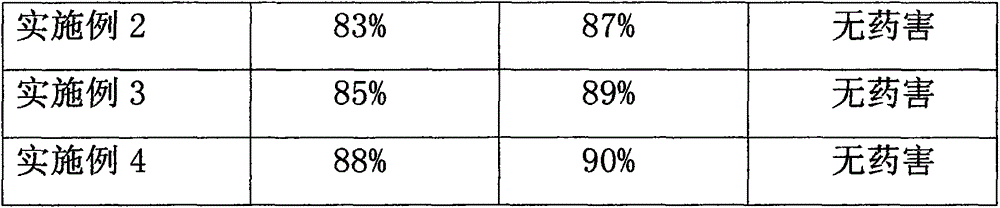

Examples

Embodiment 1

[0024] The specific weight ratio of each selected component is as follows: 3% of dimehypo technical; 0.1% of thiamethoxam technical; 5% of starch paste; 5% of urea; %.

[0025] Mix the above components evenly, pulverize them in a pulverizer for 30 seconds, take them out and mix thoroughly again. An appropriate amount of water (7 parts by weight of water per 100 parts by weight of the mixture) was added to the mixture, stirred and evenly mixed, and then the sample was extruded and granulated in an extruder. The obtained granules are dried, sized and sieved to obtain a granule of dimehypo and thiamethoxam which can be directly used for spreading.

Embodiment 2

[0027] The specific weight ratio of the selected components is as follows: 3% of the original drug of monosultap; 0.1% of the original drug of thiamethoxam; 5% of dextrin; 5% of calcium chloride; 10% of alkyl naphthalene sulfonate; Add to 100%.

[0028] Mix the above components evenly, pulverize them in a pulverizer for 30 seconds, take them out and mix thoroughly again. An appropriate amount of water (7 parts by weight of water per 100 parts by weight of the mixture) was added to the mixture, stirred and evenly mixed, and then the sample was extruded and granulated in an extruder. The obtained granules are dried, sized and sieved to obtain a granule of monosultap and thiamethoxam which can be directly applied.

Embodiment 3

[0030] The specific weight ratio of the selected components is as follows: cartap technical 3%; thiamethoxam technical 0.1%; gum 5%; magnesium chloride 5%; castor oil ethylene oxide adduct 10%; to 100%.

[0031] Mix the above components evenly, pulverize them in a pulverizer for 30 seconds, take them out and mix thoroughly again. An appropriate amount of water (7 parts by weight of water per 100 parts by weight of the mixture) was added to the mixture, stirred and evenly mixed, and then the sample was extruded and granulated in an extruder. The obtained granules are dried, sized and sieved to obtain a granule of cartap and thiamethoxam that can be directly applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com