Socket press fit armor composite pipe

A press-fit and composite pipe technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of fast aging speed, short service life, aging, etc., and achieve slow aging speed, long service life, and durability good thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

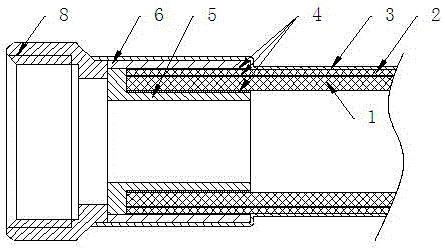

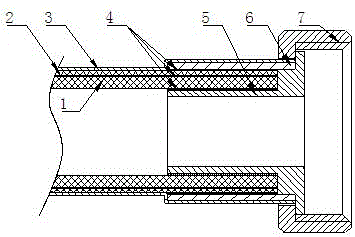

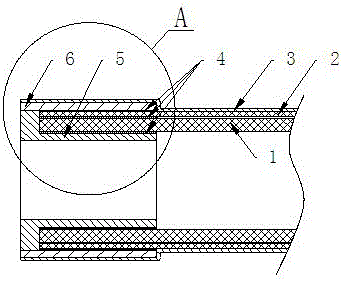

[0014] Embodiment 1: see figure 1 , figure 2 , image 3 and Figure 4 , a socket and press-fit armor composite pipe, including a connecting pipe 1 for guiding gas, the outer wall of the connecting pipe 1 is sequentially sleeved with a metal spiral pipe 2 and a heat shrinkable sleeve 3 from the inside to the outside, and the two ends of the connecting pipe 1 There is a socket press-fit pipe fitting, the socket press-fit pipe fitting includes a main body 5 and a press-fit pipe 6, and the two ends of the connecting pipe 1 and the metal spiral pipe 2 are located at the corresponding ends. There are 6 pipes, and a layer of sealant 4 is provided between the connecting pipe 1 and the main body 5, between the connecting pipe 1 and the metal spiral pipe 2, between the metal spiral pipe 2 and the compression pipe 6, and the connecting pipe 1 and the metal spiral pipe 2 It is tightly connected with the socket and press-fit pipe fittings by means of hydraulic tools. The heat-shrinkabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com