Connection plate and car

A technology for connecting plates and automobiles, which is applied in vehicle parts, bicycle accessories, bicycle safety equipment, etc., can solve the problems of the overall weight of the body structure, the increase of the welding process of the connecting parts, and the high cost of opening the molds of the connecting parts, etc., to achieve performance performance. Better, improve the collision energy absorption space, reduce the effect of mold opening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

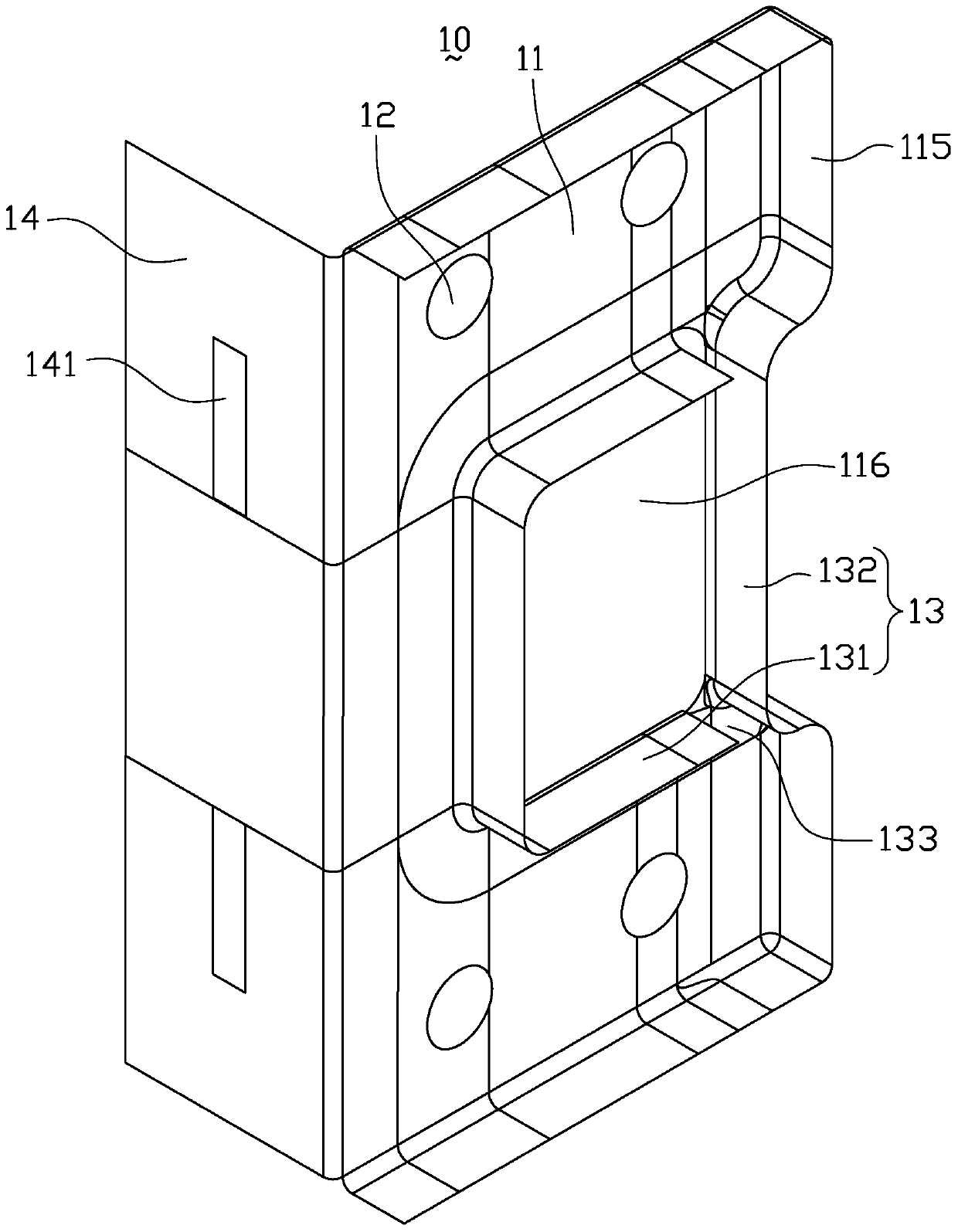

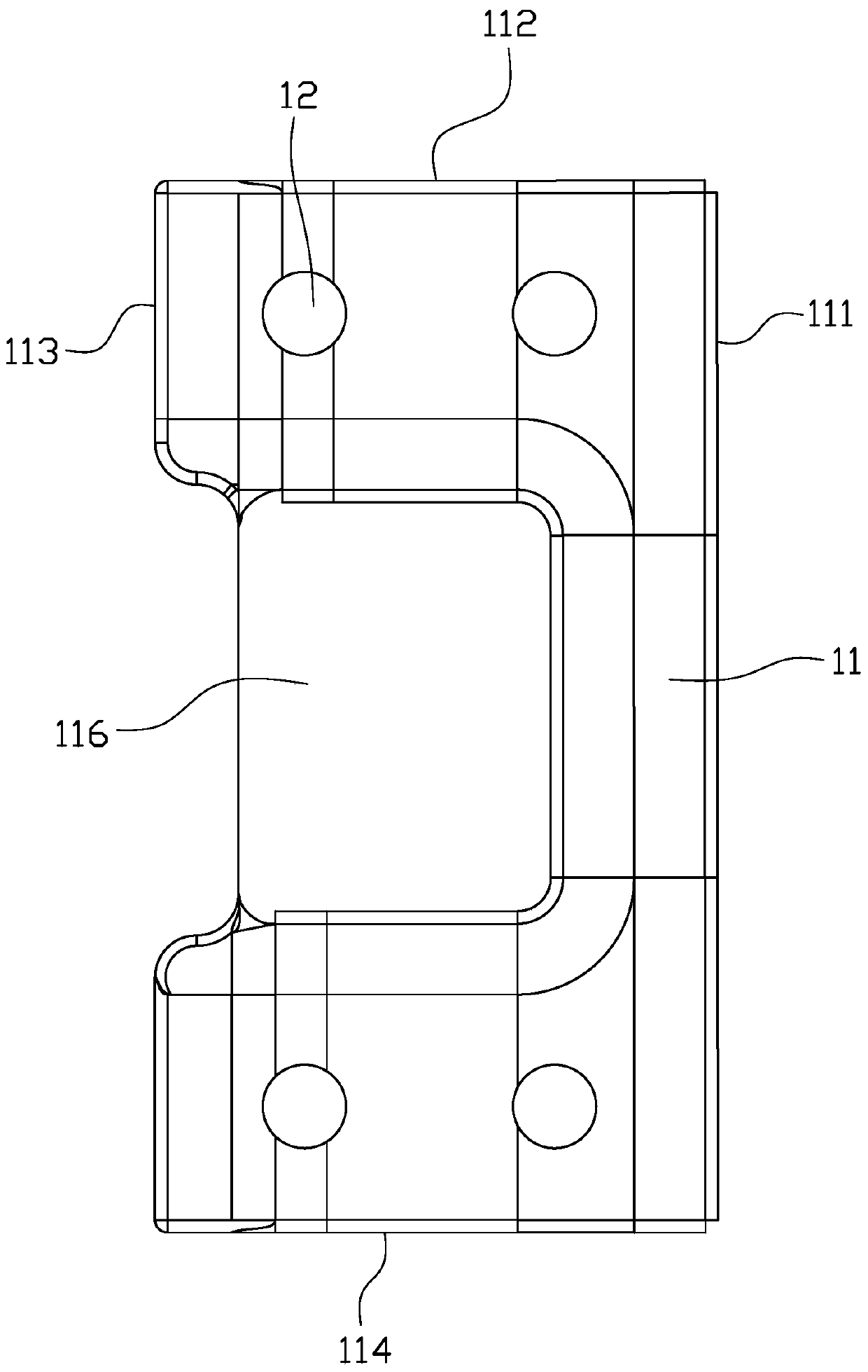

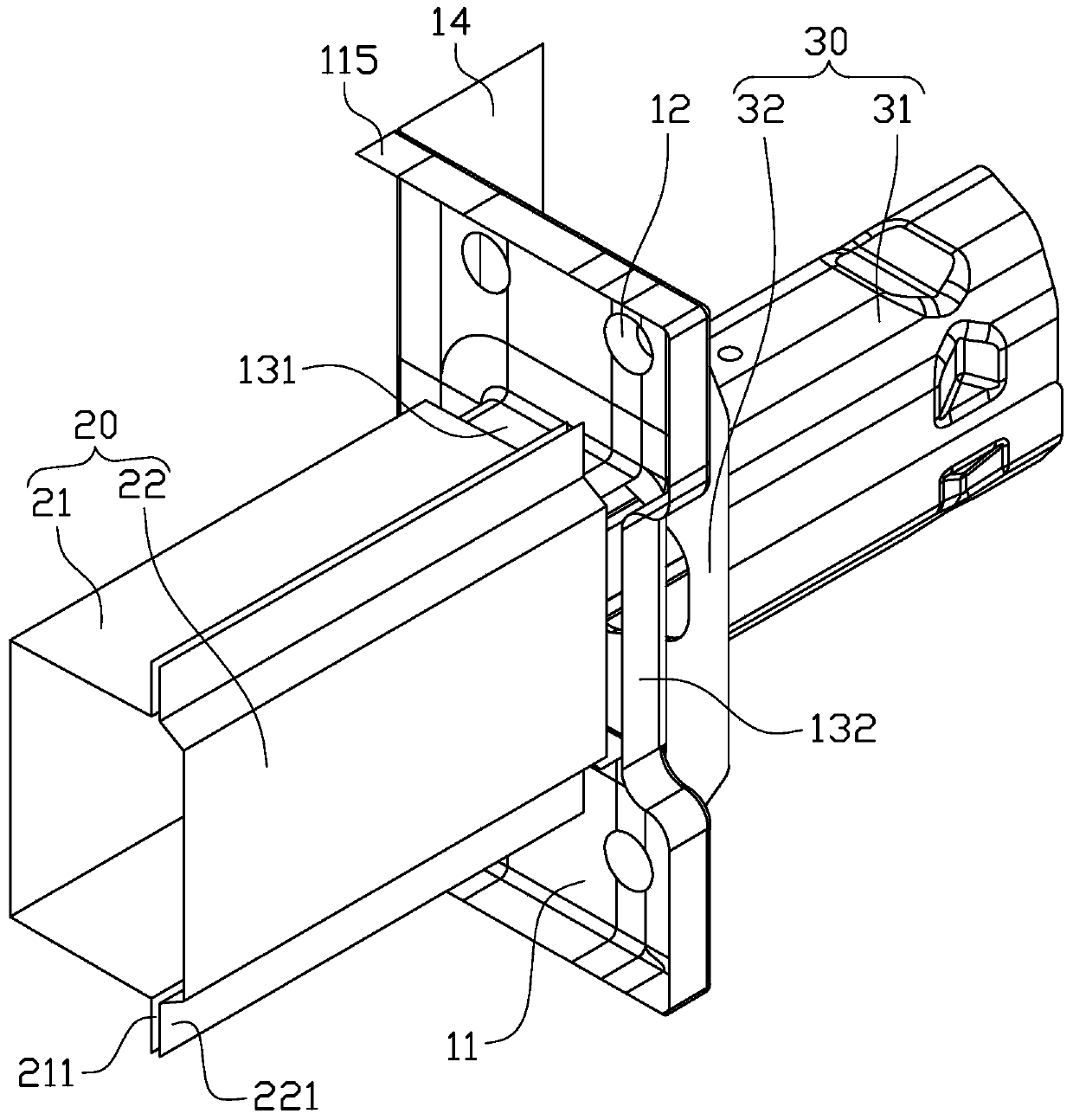

[0021] figure 1 It is a schematic structural diagram of the connection board in the embodiment of the present invention. figure 2 It is a structural schematic diagram of the connection board in another viewing angle in the embodiment of the present invention. The connection plate of the invention is used for the connection among the cooling module, the longitudinal beam and the front beam assembly of the automobile front end. Such as figure 1 and figure 2 As shown, the connection plate 10 of the present invention includes a connection plate body 11, a longitudinal beam installation portion 13 and a cooling module installation portion 14, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com