Temperature-changing sterilization tank

A temperature-variable sterilization and tank technology, which is applied in food preservation, food preparation, food science, etc., can solve problems such as harm to the human body, and achieve the effect of flavor and nutrition retention, uniform and stable cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

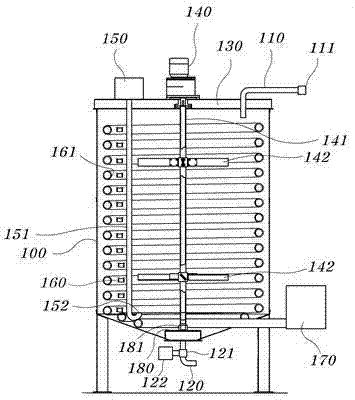

[0025] Such as figure 1 As shown, the variable temperature sterilization tank of the present invention includes a tank body 100, a tank cover 130 is provided on the top, a blocking block 180 and an outlet pipe 120 passing through the blocking block 180 are provided at the bottom, and a valve 121 is provided on the outlet pipe 120 , the valve 121 also has a valve knob 122 to control its opening and closing, and a heating resistance wire is embedded in the side wall of the tank body 100;

[0026] The cooling system includes a sequentially connected cold water joint 150, an introduction pipe 152, and a spiral jacket 161. The cold water joint 150 is arranged on the tank cover 130, the introduction pipe 152 is inserted into the tank body 100, and the spiral jacket 161 is fixed on the tank body 100. The spiral sleeve 181 on the inner wall; every time the spiral jacket 161 circles around the inner wall of the tank body 100, a hole is set on the surface wall of the spiral jacket 161 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com