A kind of preparation method of rice-like α-fe2o3 nano-powder

A nano-powder and rice-like technology, which is applied in the field of preparation of rice-like α-Fe2O3, can solve the problem that the nano-iron oxide particles cannot meet the size controllability and other problems, and achieve the effect of large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

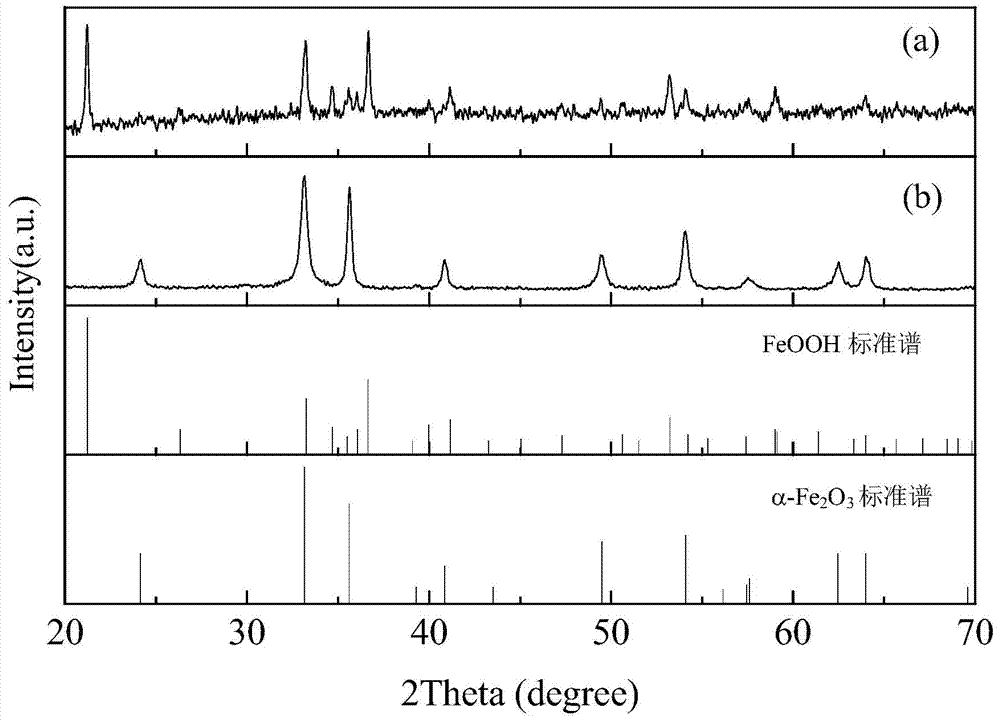

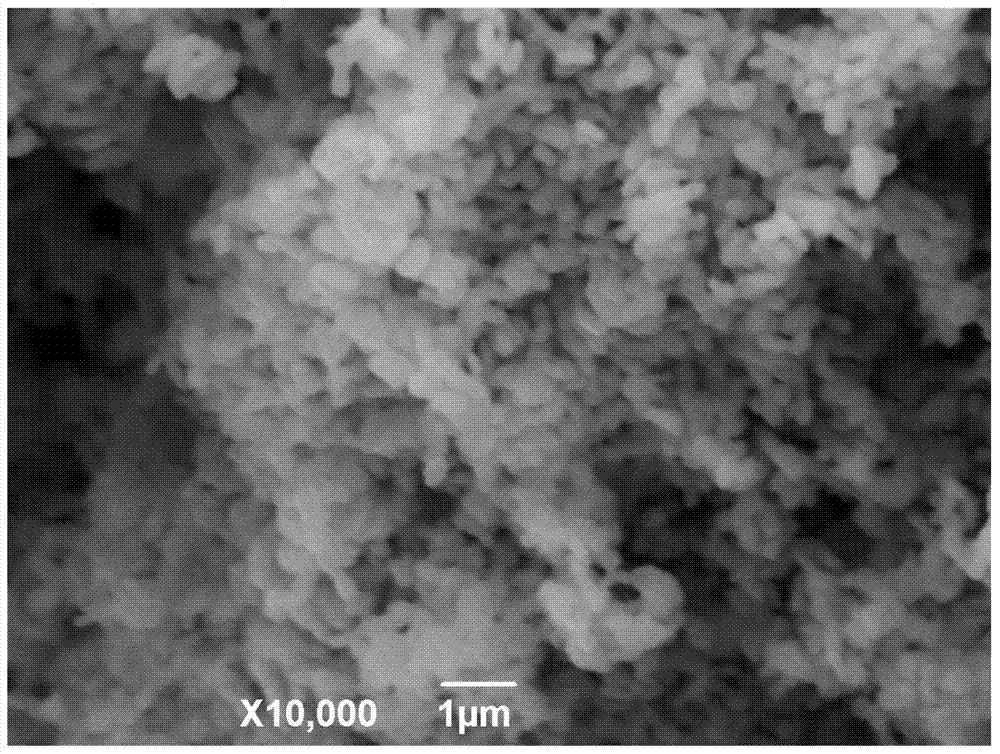

[0027] According to the needs of preparing 1mmol of FeOOH, weigh 0.36g (9mmol) NaOH and 0.40g (1mmol) FeOOH respectively 2 (SO 4 ) 3 , were dissolved in 9ml of deionized water. Fe was then mixed with 2 (SO 4 ) 3 The solution was added dropwise to the NaOH solution, and after the precipitation reaction was completed, 0.2 g of C 19 h 42 BrN acts as a surfactant. The mixed solution was transferred into a 25ml polytetrafluoroethylene reactor, and subjected to hydrothermal reaction at 220° C. for 2 hours, and the obtained product was needle-shaped FeOOH powder. The obtained FeOOH was raised from room temperature to 1000°C at a heating rate of 10°C / min in a muffle furnace and then directly cooled to obtain rice-shaped α-Fe 2 o 3 Nano powder. Its XRD spectrum is as figure 1 As shown, its scanning electron microscope picture is shown in figure 2 shown.

Embodiment 2

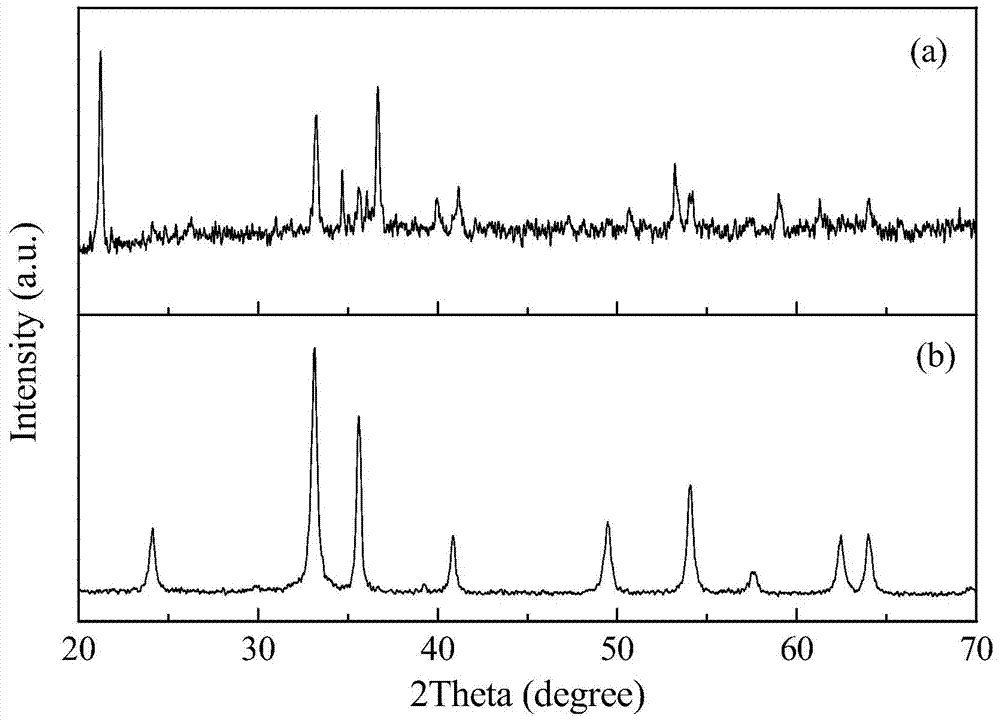

[0029] According to the needs of preparing 1mmol of FeOOH, weigh 0.36g (9mmol) NaOH and 0.40g (1mmol) FeOOH respectively 2 (SO 4 ) 3 , were dissolved in 9ml of deionized water. Then, while stirring, the Fe 2 (SO 4 ) 3 The solution was added dropwise to the NaOH solution, and after the precipitation reaction was completed, 0.3 g of C 19 h 42 BrN acts as a surfactant. The mixed solution was transferred into a polytetrafluoroethylene reactor, and hydrothermally reacted at 220° C. for 2 hours, and the obtained product was needle-shaped FeOOH powder. The obtained FeOOH was raised from room temperature to 1000°C at a heating rate of 10°C / min in a muffle furnace and then directly cooled to obtain rice-shaped α-Fe 2 o 3 Nano powder. Its XRD spectrum is as image 3 As shown, its scanning electron microscope picture is shown in Figure 4 shown.

Embodiment 3

[0031] According to the needs of preparing 1mmol of FeOOH, weigh 0.36g (9mmol) NaOH and 0.40g (1mmol) FeOOH respectively 2 (SO 4 ) 3 , were dissolved in 9ml of deionized water. Fe was then mixed with 2 (SO 4 ) 3 The solution was added dropwise to the NaOH solution, and after the precipitation reaction was completed, 0.3 g of C 19 h 42 BrN acts as a surfactant. The mixed solution was transferred into a polytetrafluoroethylene reactor, and hydrothermally reacted at 200° C. for 2 hours, and the obtained product was needle-shaped FeOOH powder. The obtained FeOOH was raised from room temperature to 1000°C at a heating rate of 10°C / min in a muffle furnace and then directly cooled to obtain rice-shaped α-Fe 2 o 3 Nano powder. Its XRD spectrum is as Figure 5 As shown, its scanning electron microscope picture is shown in Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com