Anti-rollover device for mine car

A technology for anti-rollover and mining cars, which is applied in transportation and packaging, railway car body parts, and vehicle route interaction equipment, etc. Easy to operate, energy saving, anti-rollover remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

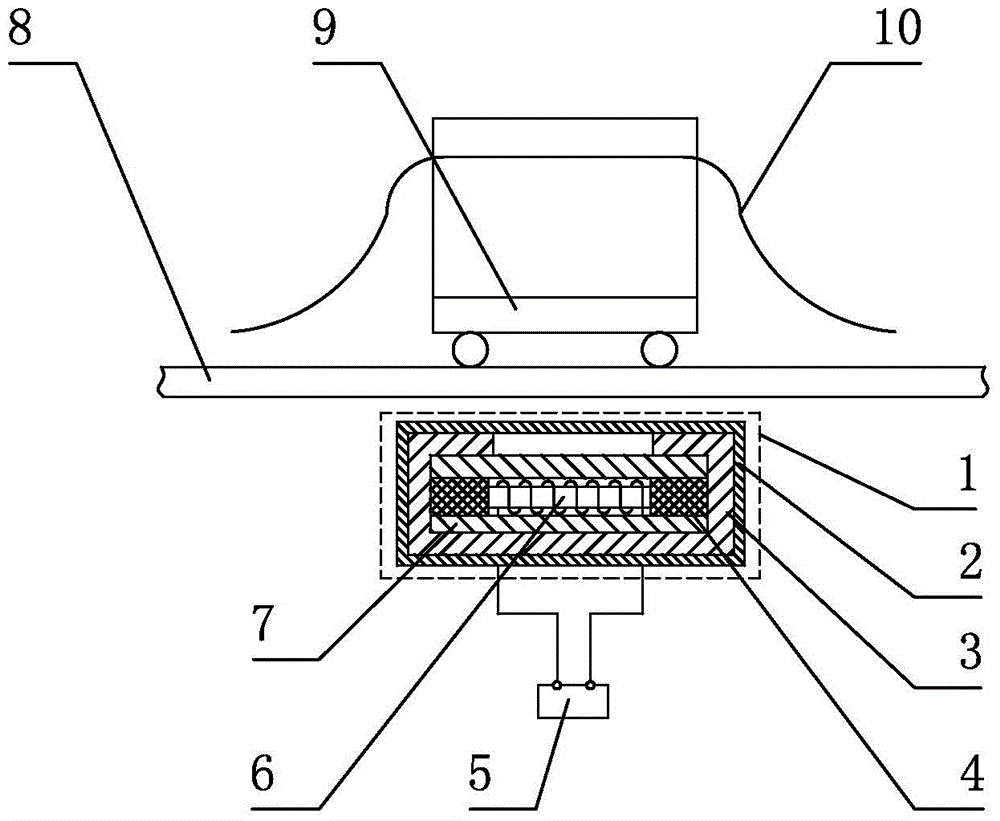

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as Figure 1~2 As shown, the mine car anti-rollover device includes a rail 8 and a curved rail 10 on one side of the rail 8, and an electromagnetic device 1 is embedded below the rail 8 corresponding to the middle section of the curved rail 10, and the electromagnetic device 1 is arranged on the track 8. Between the track on rail 8 both sides, its two ends do not exceed the position of sleeper 11 two ends, because track is irony, can shield magnetic force, therefore, make magnetic force be between two tracks of track 8, bring into play maximum effect. The electromagnetic device 1 includes a rubber shell 2. The center of the rubber shell 2 is provided with an electromagnet 6. The iron core of the electromagnet 6 is made of large-diameter silicon steel, and the length of the iron core is 300-500 mm. The coil is densely wound on it to ensure tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com