Slurry replacement device for retarded cement slurry in freezing method construction

A technology in cement slurry and construction, which is applied in the field of slow-setting cement slurry replacement mud device, can solve problems such as powerlessness and flooding accidents, and achieve the effect of ensuring the plugging effect and reducing the flooding accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

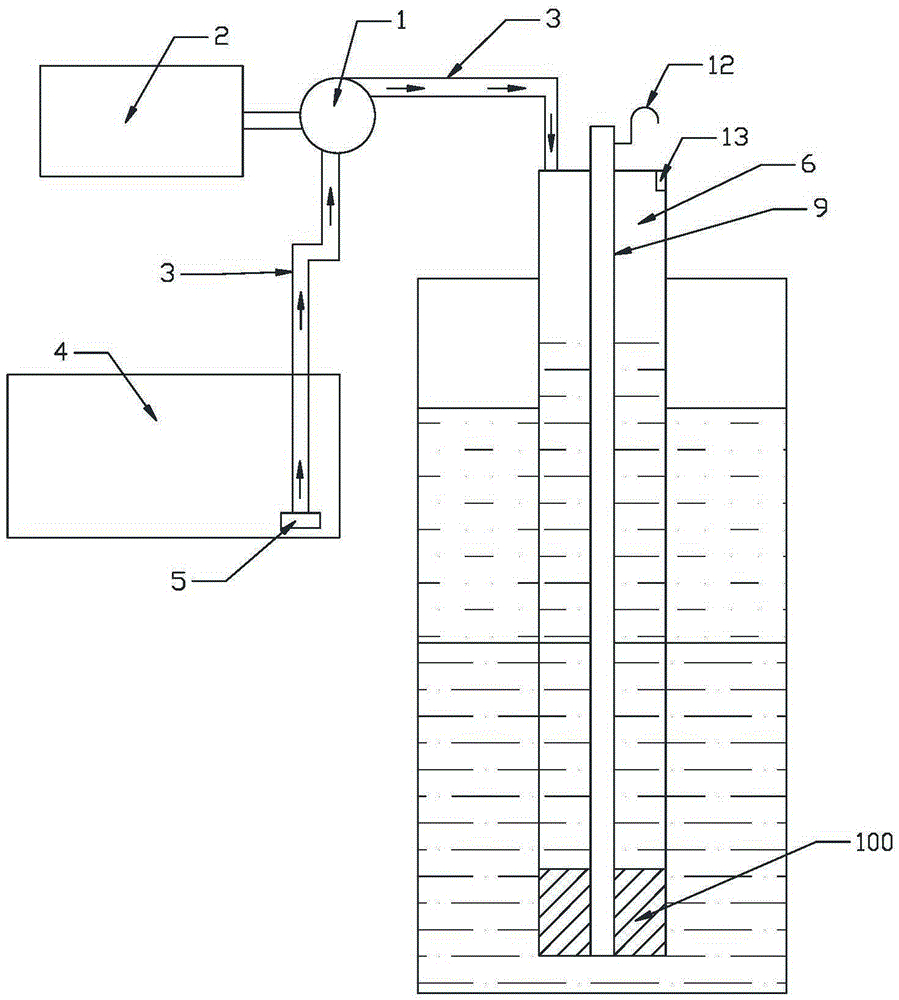

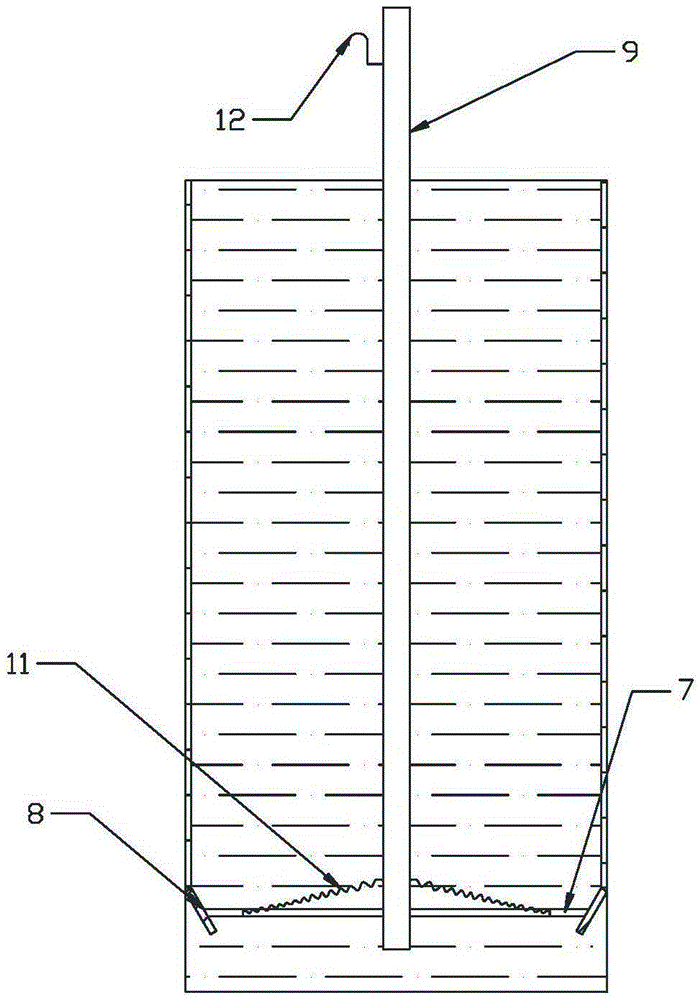

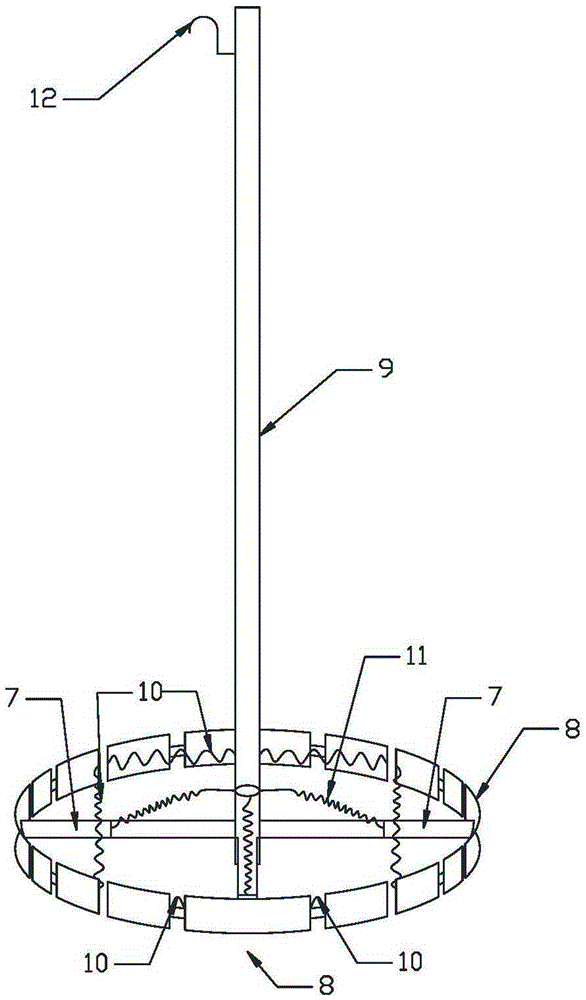

[0018] Such as Figure 1 to Figure 3 As shown, the slow-setting cement slurry replacement slurry device in the freezing method construction of this embodiment includes a slurry delivery pump 1, a motor 2, a high-pressure slurry pipeline 3, a slurry pool 4 and a slurry filter mechanism 5, and also includes a slurry delivery Pipe 6, borehole wall scraping mechanism 100, push-out mechanism and positioning mechanism. The borehole wall scraping mechanism 100 is located in the cement slurry delivery pipe 6. Drive connection and can push out the borehole wall scraping mechanism 100 from the bottom end of the cement slurry delivery pipe 6, and the positioning mechanism is used to keep the borehole wall scraping mechanism 100 from the cement slurry delivery pipe 6 After the bottom end is pushed out, no axial displacement occurs along the cement slurry conveying pipe 6 . The borehole wall scraping mechanism 100 includes a crawler-type scraper assembly 8, a connecting plate 7, a scraper...

Embodiment 2

[0022] Such as Figure 4~7 As shown, the borehole wall scraping mechanism 100 includes a central installation rod 14 and an upwardly curved arc-shaped rubber scraper 15, and the arc-shaped rubber scraper 15 is installed at the bottom end of the central installation rod 14 and along the The circumferential distribution of the central installation rod 14, the positioning mechanism includes a positioning disc 16 located in the cement slurry delivery pipe 6 and an annular boss 17 on the inner wall of the bottom end of the cement slurry delivery pipe 6, the positioning circle A slurry leakage hole 18 is opened on the disk 16, the diameter of the positioning disk 16 is smaller than the inner diameter of the cement slurry delivery pipe 6, the diameter of the positioning disk 16 is larger than the aperture formed by the annular boss 17 and both The difference is greater than 6 mm and less than 10 mm (too large is not conducive to the passage of cement slurry, too small to effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com