Electro-magnetic dual-salient-pole motor rotor

A technology of electric excitation doubly salient poles and motor rotor, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of rotor fracture, large centripetal force, motor burnout, etc., and achieve improved stability, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

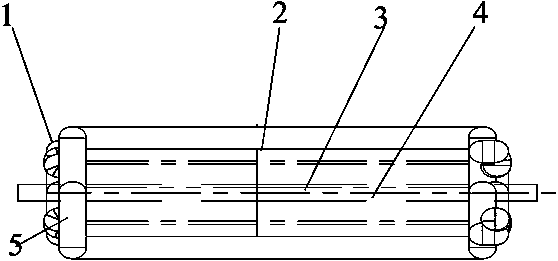

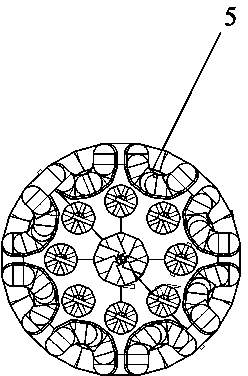

[0015] Such as figure 1 with figure 2 As shown, the rotor of the electric excitation double salient pole motor of the present invention includes a rotor central shaft 4, a rotor iron core 3, a rotor punching piece 2, and a rotor core filling block 5. The rotor iron core 3 is located at the outer ring of the rotor central axis 4, and the rotor punching piece 2 is located on the periphery of the rotor core 3, and the rotor core filling block 5 is fixed on both ends of the rotor punch 2 with rivets 1.

[0016] The material of the rotor iron core filling block 5 is polytetrafluoroethylene, and the cost of this material is the lowest. A layer of insulating varnish is coated on the periphery of the rivet 1, and the insulating varnish plays an insulating role to prevent the surface of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com