Automatic trigger machine

An automatic and rack-mounted technology, applied in the field of automatic triggering machines, can solve the problems of inability to automatically feed and automatically recover blanks and material heads, and achieve the effects of improving work efficiency, product quality, and accurate delivery positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

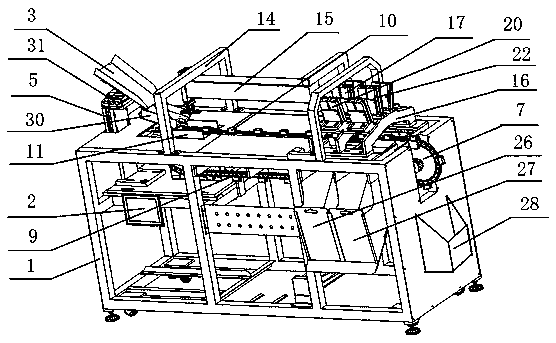

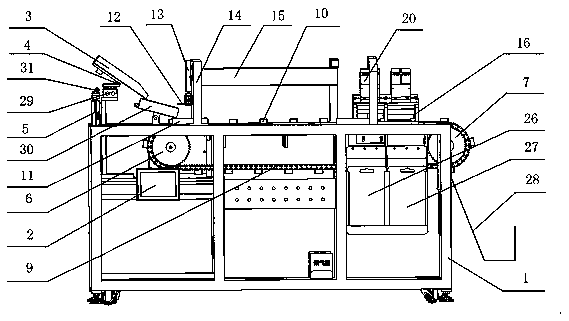

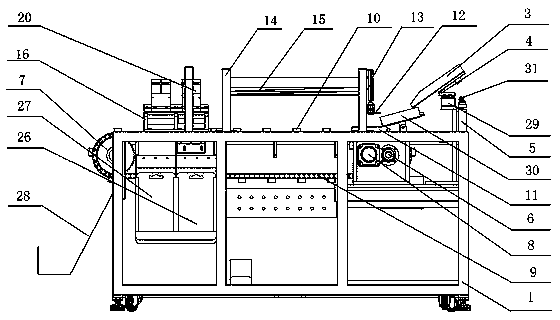

[0023] Such as figure 1 , figure 2 , image 3 The shown automatic triggering machine includes a frame 1 and a PLC control unit 2 arranged on the frame 1. A conveyor belt for conveying die-casting parts is set on one side of the frame 1. The conveyor belt can be connected with the outlet of the die-casting machine. The die-casting parts produced by the die-casting machine are transferred to the corresponding position to realize the automatic transfer function; a feeding device is installed on the frame 1 at the outlet of the conveyor belt, and the feeding device includes a feeding box 3, which is set on both sides of the feeding box 3 The side plate can prevent the die casting from slipping out from the side when the conveyer belt is transferred to the feed box 3; To drive the feed box 3 to rotate, a rotating wheel can also be set at the bottom of the feed box 3, and the rotation is driven by the bar teeth; the bottom of the feed box 3 is connected with the rotating part by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com