A kind of manufacturing method of seamless steel pipe for shock absorber

A technology of seamless steel pipes and manufacturing methods, which is applied in the field of manufacturing special steel pipes for motorcycle shock absorber struts, can solve the problems of lack of high toughness, potential safety hazards of motor vehicle use, and easy cracking of steel pipes, and improve technical performance and service life, and the effect of reducing driving safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

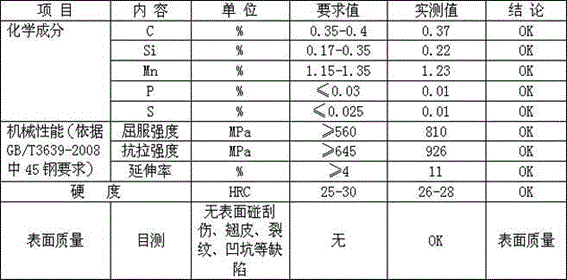

[0025] The invention discloses a method for manufacturing a seamless steel pipe for a shock absorber, which consists of C: 0.35%, Si: 0.17%, Mn: 1.15%, P: ≤0.030%, S: ≤0.025%, and the rest is the percentage content of iron components Composition, the method includes the steps of:

[0026] Step 1: batching, tube forming;

[0027] The above ingredients are taken out for batching, put into the pipe making mold, and undergo heat processing and cooling to form a solid structure of round steel billet;

[0028] Step 2: Forming treatment;

[0029] The round steel billet is cut and sheared with a cutting device, processed into a billet of 0.8-1.2m, and transported to the heating furnace through the conveying platform for full heating, because the Mn content in the steel pipe is 1.15, and the percentage between Mn and C is 3:1, it has strong sensitivity when heating perforation, and the heating temperature should be controlled within the range of 1220°C. The heating device adopts a co...

Embodiment 2

[0044] A method for manufacturing seamless steel pipes for shock absorbers, which consists of C: 0.40%, Si: 0.35%, Mn: 1.35%, P: ≤0.030%, S: ≤0.025%, and the rest is iron. The method includes the following steps:

[0045] Step 1: batching, tube forming;

[0046] Take out the above-mentioned ingredients for batching, put them into the pipe-making mold, and undergo smelting, thermal processing, and cooling to form a solid structure of the round pipe billet;

[0047] Step 2: Forming treatment;

[0048] Cut the round steel billet with a cutting device, process it into a billet of 0.8-1.2m, and transport it to the heating device for full heating through the conveying platform. Because the Mn content in the steel pipe is 1.35%, the percentage between Mn and C It is 3:1, it has strong sensitivity when heating perforation, and the heating temperature should be controlled within the range of 1230°C. The heating device adopts a computer automatic temperature closed-loop control system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com