A test method for a thin-walled cylindrical shell member vibration test system

A thin-walled cylinder and vibration testing technology, which is applied in the testing of machines/structural components, vibration testing, measuring devices, etc., can solve problems such as difficulties, low measurement efficiency, and low measurement stability, and achieve high measurement efficiency and stable measurement sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

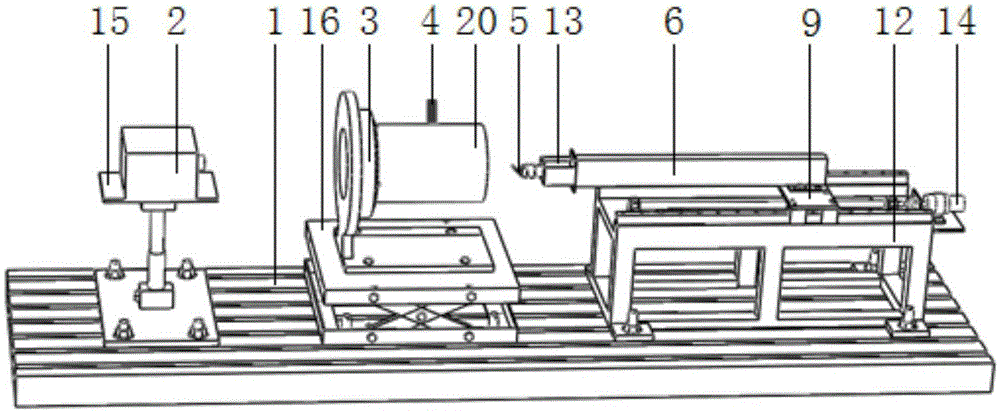

[0035] Such as figure 1 , 2 , 3, a thin-walled cylindrical shell component vibration testing system, including a base 1, a laser Doppler vibrometer 2, a specimen mounting table 3, a vibrator 4 and a laser reflection unit, the laser multiple The Puler vibrometer 2 is arranged on the base 1, the test piece mounting platform 3 is arranged on the base 1, and the laser emitting end of the laser Doppler vibrometer 2 corresponds to the test piece mounting platform 3; The vibrator 4 is located on the side of the test piece mounting table 3; the laser reflection unit is arranged on the base 1 through a fixed bracket 12;

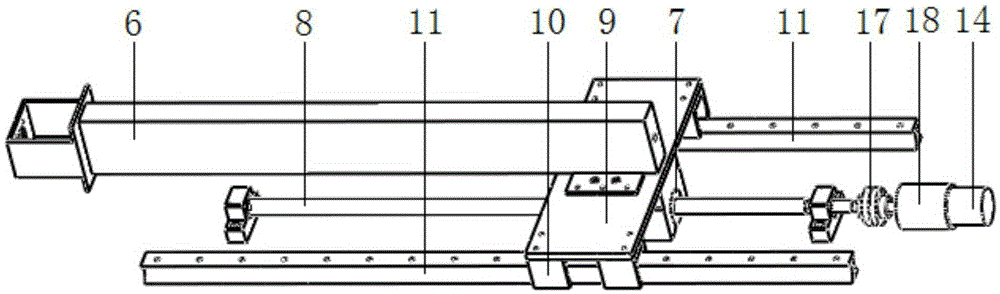

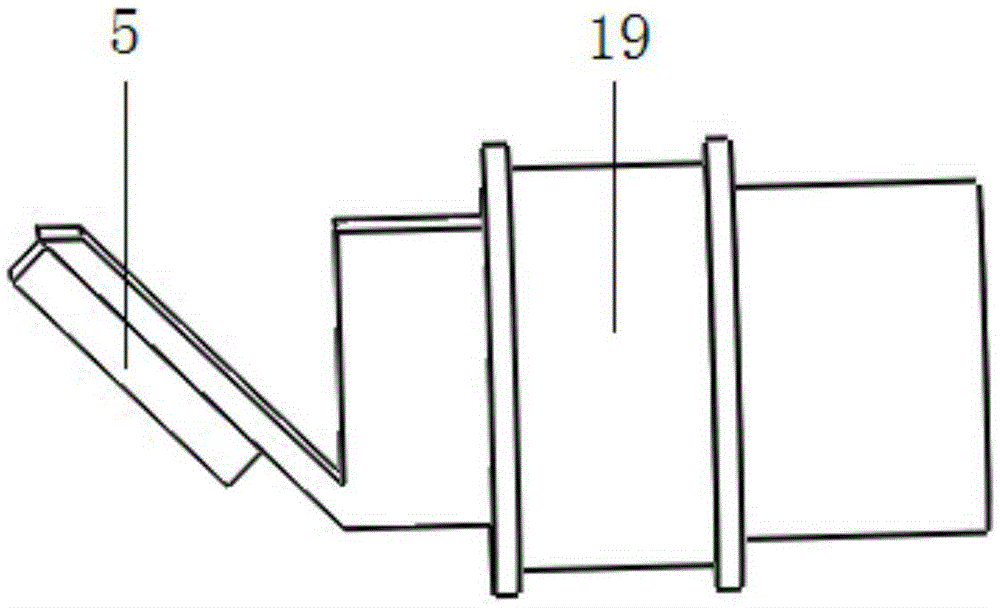

[0036] The laser reflection unit includes a reflector 5 and a transmission part. The transmission part includes a guide rail 11, a slider 10, a sliding plate 9, a lead screw 8, a screw nut 7 and a measuring arm 6. The guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com