A method for centering adjustment of a main shaft bearing shaft system of a wind power generating set

A technology for wind turbines and main shaft bearings, which is used in the assembly of wind turbines, shafts and bearings, and bearings in rotary motion, etc., can solve the problems of oil leakage, temperature rise and wear of main shaft bearing seals, reduce maintenance costs, and ensure the use of longevity, effectiveness in addressing temperature rise issues and early wear and failure issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

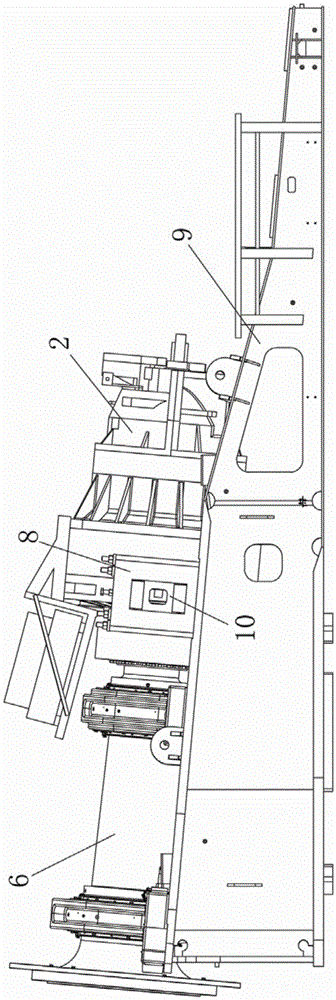

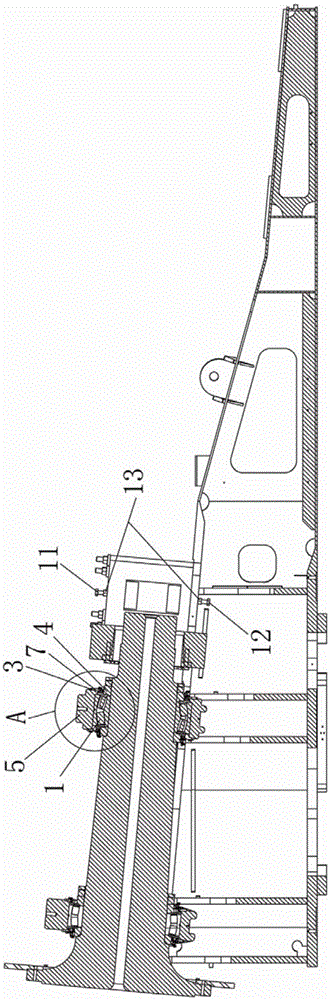

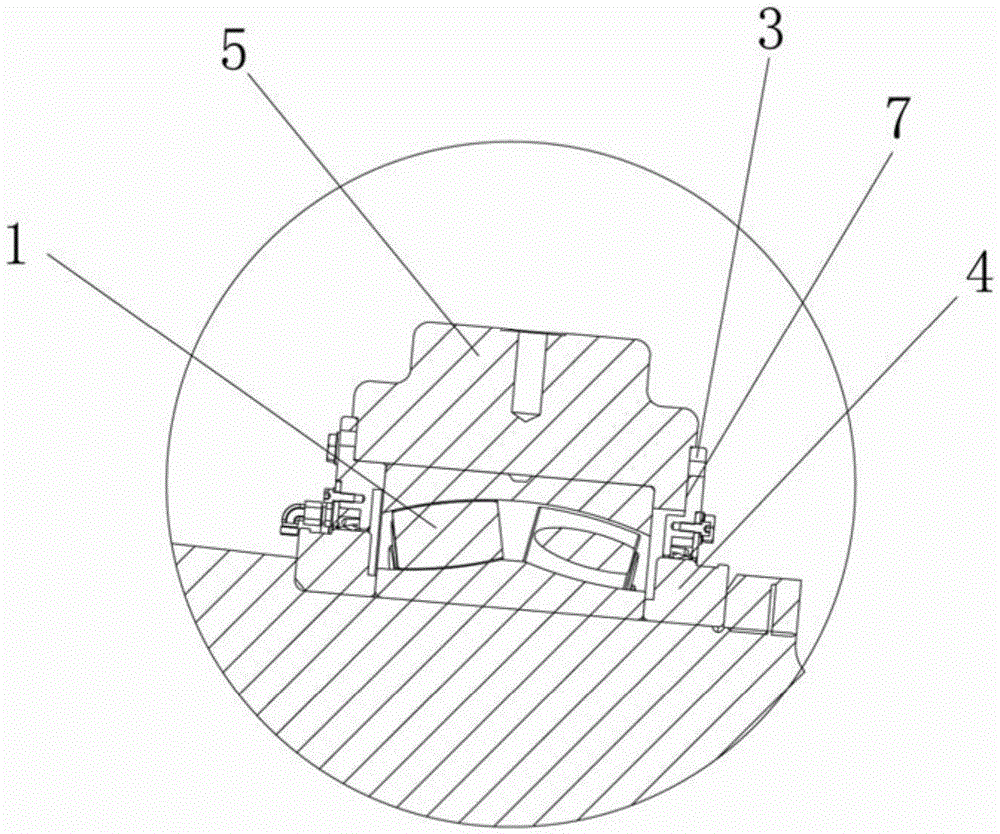

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples.

[0036] As shown in Table 1 below, the detection and adjustment records of the Xiangyang wind field and the Hongnijing wind field are given.

[0037] Table 1 Detection and adjustment records of Xiangyang wind field and Hongnijing wind field

[0038]

[0039] It can be seen from the above table that the verticality between the main shaft and the end cover installation surface of all oil-leaking fans is very large, such as Hongnijing 22# and 11#, which meet the requirements after adjustment, while the other three such as Xiangyang 98# 17# and 56# red mud wells do not need to be adjusted because the angle between the main shaft and the end cover installation surface is small and there is no oil leakage. Therefore, the main reason affecting the oil leakage of the main shaft sealing ring and the early wear of the 530 bearing is whether the verticality between the main shaft and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com