Apparatus and method for processing antimony ore acidic waste water

A technology of acid wastewater and antimony ore, which is applied in mining wastewater treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of large maintenance management investment, high operating cost, and unsustainability, and achieves no need for electric equipment, Environmental risk reduction, adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

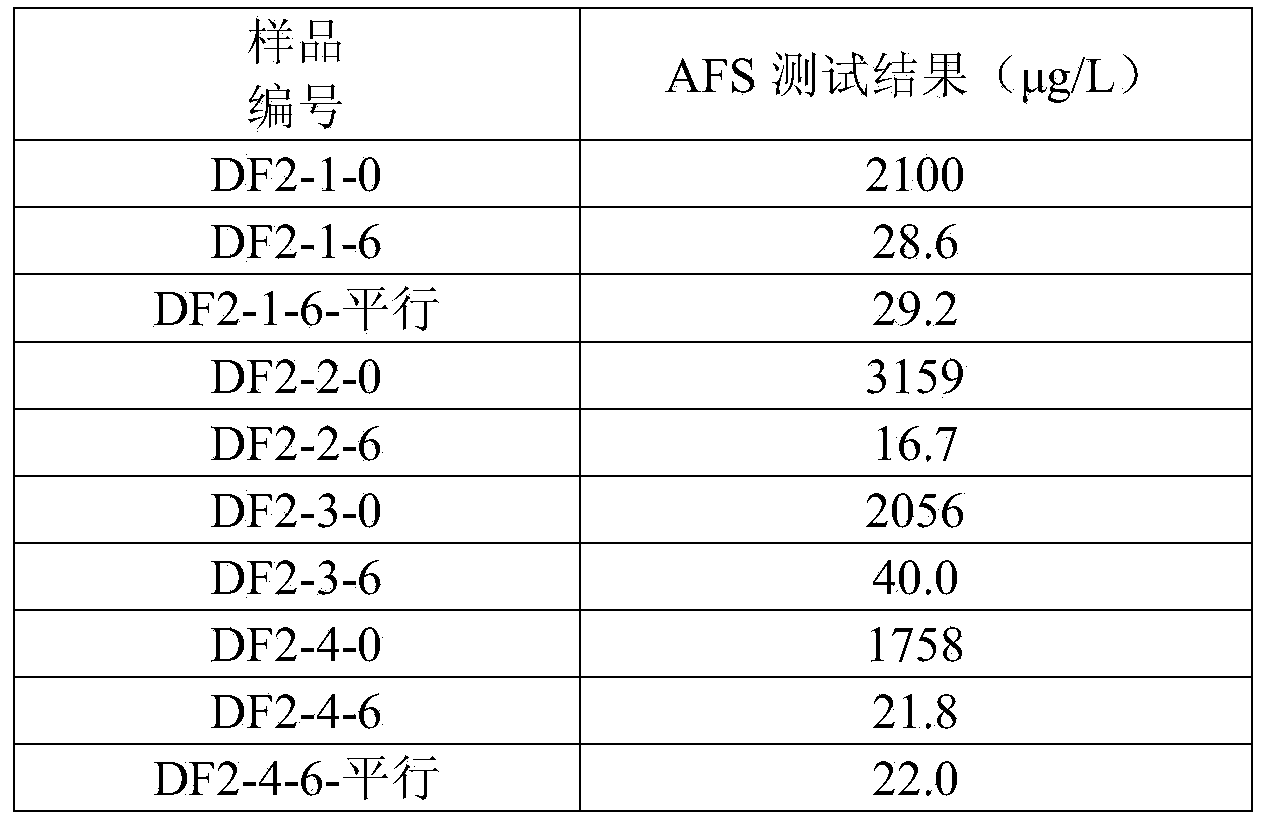

[0032] The following examples are further detailed descriptions of the present invention.

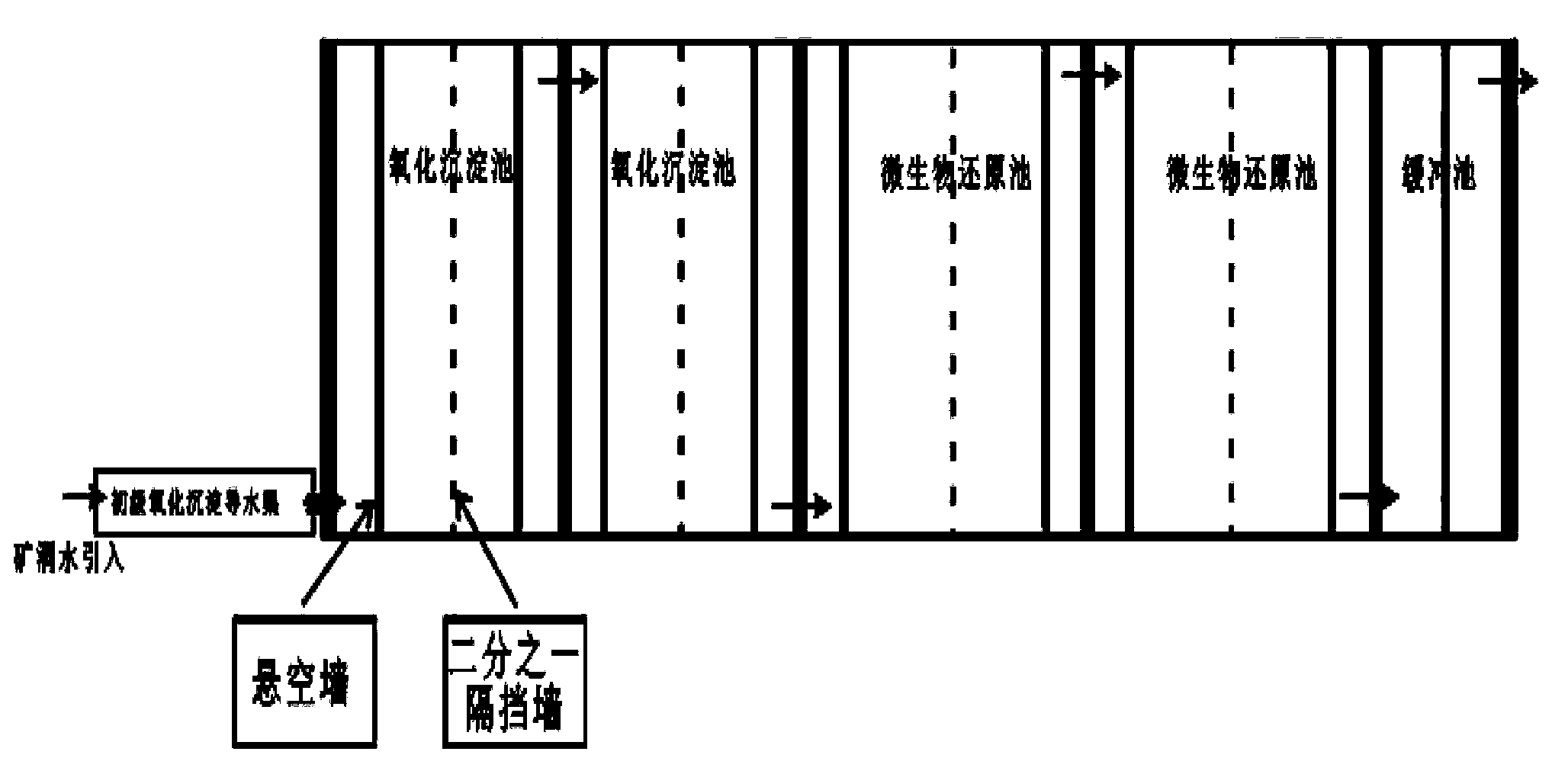

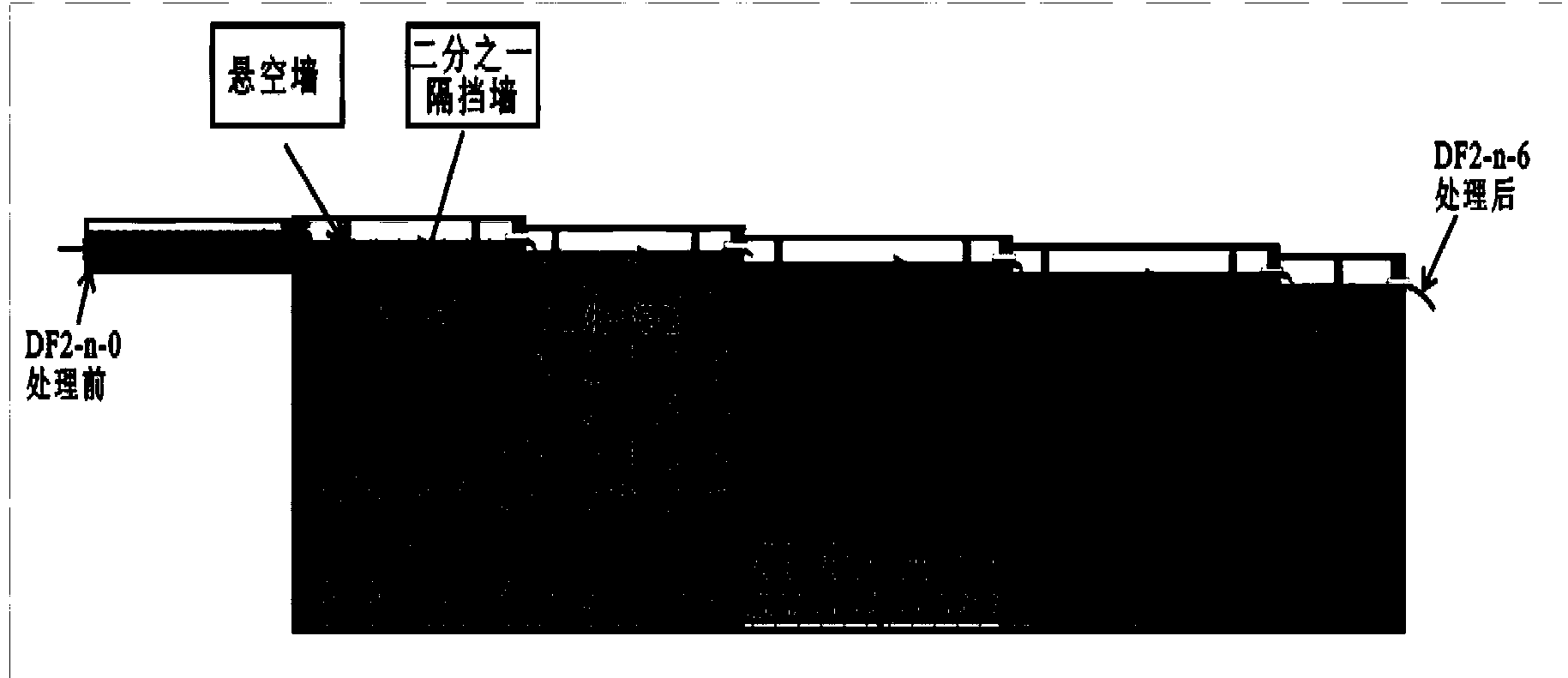

[0033] as attached figure 1 and 2 As shown, the device for processing antimony ore acid wastewater of the present invention is composed of a shallow water diversion oxidation sedimentation tank, a secondary oxidation sedimentation tank, a tertiary oxidation sedimentation tank, a primary microbial reduction tank, a secondary microbial reduction tank and a buffer pool; The shallow water diversion oxidation sedimentation tank is located at the front, followed by the secondary oxidation sedimentation tank, the third oxidation sedimentation tank, the first microbial reduction tank, the second microbial reduction tank and the buffer tank; the shallow water diversion oxidation sedimentation tank and the second oxidation The upper connection of the sedimentation tank, the secondary oxidation sedimentation tank, the tertiary oxidation sedimentation tank, the first microbial reduction tank, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com