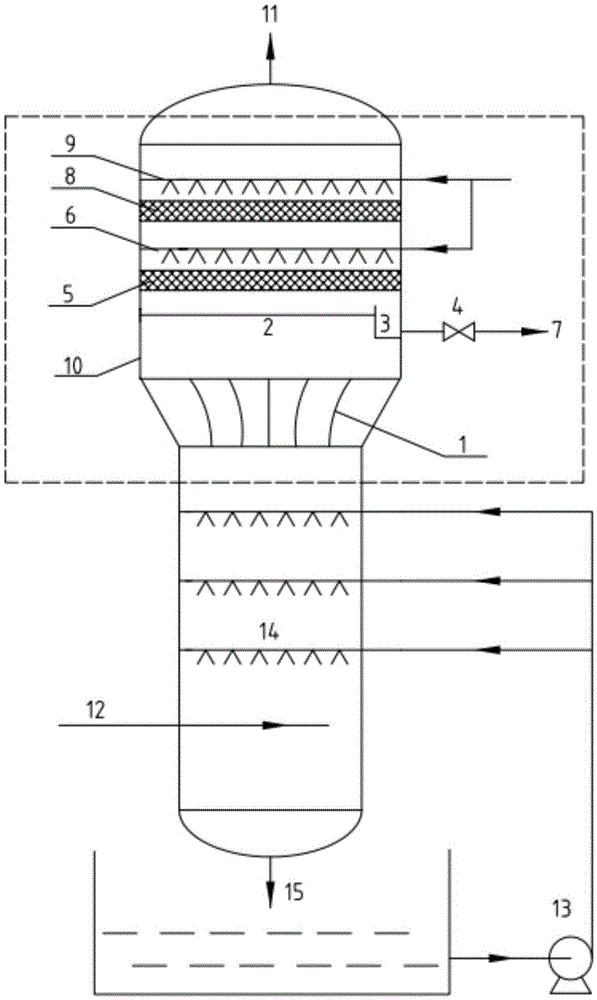

A desulfurization absorption tower for eliminating "gypsum rain" in flue gas desulfurization of coal-fired boilers

A desulfurization absorption tower, coal-fired boiler technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of energy consumption and can not really solve the problem, and achieve low operating energy consumption and strong industrial reliability , the effect of large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: The flue gas of a coal-fired boiler in a 300MW power plant adopts a wet lye full flue gas desulfurization process. The desulfurization system mainly includes WFGD compressor fan, desulfurization absorption tower, slurry circulation pump, gypsum dehydrator, etc. The diameter of the desulfurization absorption tower is 12600mm, and there are two-stage demisters above it, and GGH is used for heat exchange before the flue gas is discharged. Since the day of normal operation, it was found that the phenomenon of gypsum rain around the chimney was serious. After testing, the liquid foam content in the discharged flue gas is more than 260mg / m3, and the diameter of the liquid droplets is more than 20μm. With the increase of the operating time of the unit, the pressure difference of the mist eliminator is getting higher and higher, and the liquid foam content in the flue gas has also increased significantly, showing a worsening trend, and the second mist eliminator is ...

Embodiment 2

[0022] Example 2: The flue gas of a coal-fired boiler of a 150MW self-provided power plant adopts a wet lye full flue gas desulfurization process. The desulfurization system mainly includes compressor fan, desulfurization absorption tower, slurry circulation pump, gypsum dehydrator, etc. The diameter of the desulfurization absorption tower is 8800mm, and there are two-stage demisters above it, and GGH is used for heat exchange before the flue gas is discharged. After the completion, the operation found that the phenomenon of gypsum rain around the chimney was serious. After testing, the liquid foam content in the discharged flue gas is more than 312 mg / m3, and the diameter of the liquid droplets is mostly more than 20 μm. With the increase of the operating time of the unit, the pressure difference of the mist eliminator is getting higher and higher, and the liquid foam content in the flue gas has also increased significantly, showing a worsening trend, and the second mist eli...

Embodiment 3

[0025] Example 3: The flue gas of a 300MW×2 coal-fired boiler power plant adopts a wet lye full flue gas desulfurization process, and a desulfurization system is combined. The desulfurization system mainly includes compressor fan, desulfurization absorption tower, slurry circulation pump, gypsum dehydrator, gypsum liquid oxidation system, etc. The desulfurization absorption tower is rectangular 20000×16000mm 2 , There is a two-stage demister above it, and GGH is used for heat exchange before the flue gas is discharged. After the completion, the operation found that the phenomenon of gypsum rain around the chimney was serious. After testing, the liquid foam content in the discharged flue gas is more than 363 mg / m3, and the diameter of the liquid droplets is mostly more than 20 μm. With the increase of the operating time of the unit, the pressure difference of the mist eliminator is getting higher and higher, and the liquid foam content in the flue gas has also increased signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com