A comprehensive processing method and device for thread-free cocoon and pupa lining of automatic silk reeling machine

A technology for comprehensive processing and threadless cocoons, applied in the direction of silk reeling, etc., which can solve the problems of inability to reel normally, affecting the production and quality of silk production, and hindering the removal of positive thread cocoons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

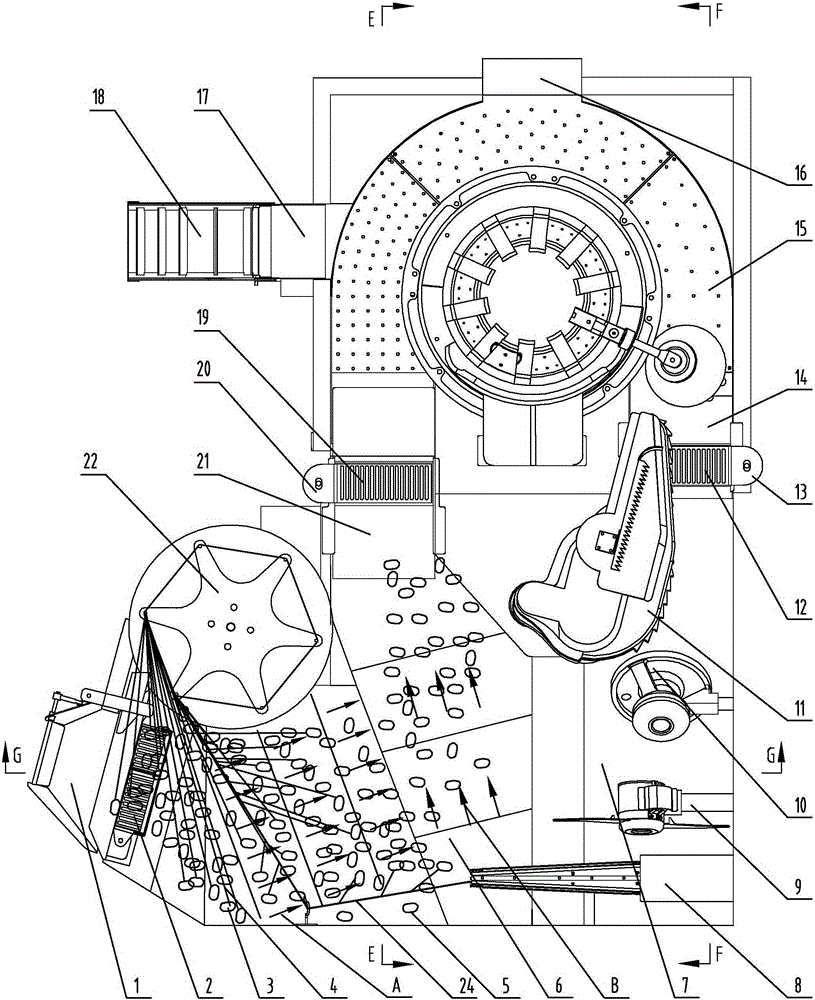

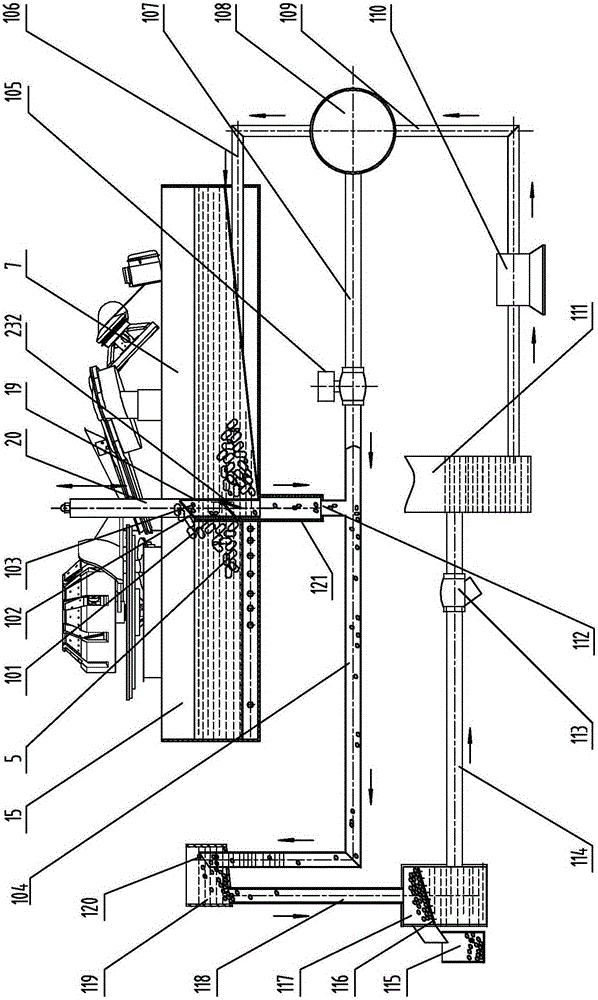

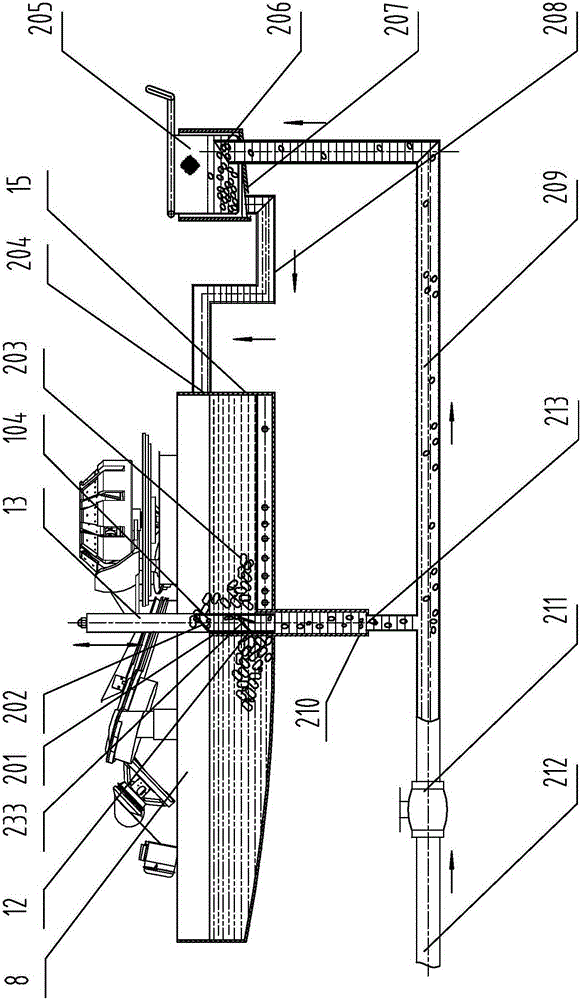

[0039] A kind of automatic silk reeling machine that the present embodiment provides thread-free cocoon and chrysalis liner comprehensive treatment device, such as figure 1 As shown, the unthreaded cocoon 5 from the silk reeling section enters the Suoxu pot 15 from the Luoxu cocoon plus cocoon opening 17 through the Luoxu cocoon conveyor belt 18, and the new cocoon enters the Suoxu pot 15 from the new cocoon plus cocoon mouth 16, after threading The threaded cocoon 203 is moved into the threading pot 7 by the threaded cocoon lifting bucket 13 through the threaded cocoon adding cocoon mouth 14, through the sawtooth plate threading mechanism 11, the eccentric plate threading mechanism 10, the needle fishing 9, threading and silk removal Apparatus 8 completes threading work, obtains Zhengxu cocoon 3 (a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com