Pneumatic-based large-scale high-weight horizontal impact test bench

An impact test, high-level technology, applied in the direction of impact test, measurement device, machine/structural component testing, etc., can solve the problems of insufficient assessment of spacecraft products, high quality, and inability to fully expose product design and manufacturing defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The pneumatic large-scale high-level impact test bench of the present invention will be described in detail below in conjunction with the accompanying drawings. The specific implementation is only for the purpose of illustration and is not intended to limit the protection scope of the present invention.

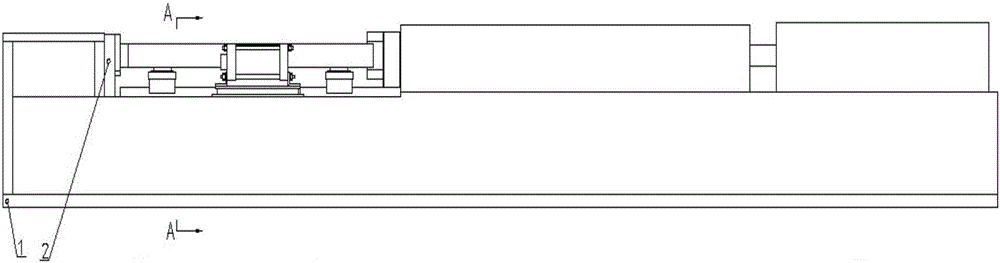

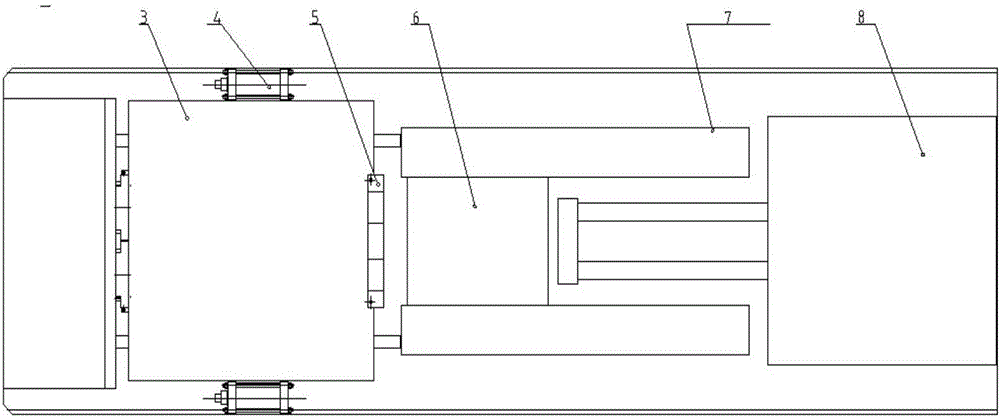

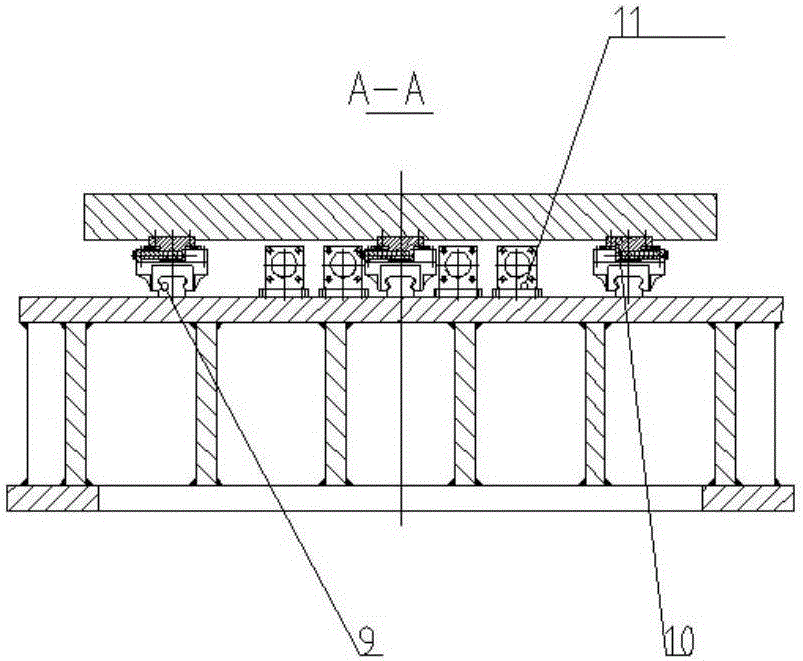

[0032] refer to Figure 1a-1c , Figure 1a-1c Respectively show the front view, top view and corresponding cross-sectional view of A-A section of the pneumatic large-scale high-weight horizontal impact test bench of the present invention. According to the accompanying drawings, it can be known that the pneumatic large-scale high-level impact test bench of the present invention includes a cylinder assembly, an impact assembly, a table assembly, an impact assembly reset cylinder, and an impact table base. Among them, the schematic diagram of the structure of the cylinder assembly based on the pneumatic large-scale high-level horizontal impact test bench of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com