Thermal insulation waterproof daub and preparation method thereof

A technology of waterproof glue and antifungal agent, which is applied in the field of architectural coatings, can solve the problems of large amount of cementing materials, etc., and achieve the effects of short construction period, good flexibility, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 40% of sodium silicate aqueous solution, 0.1% of antifungal agent, 0.8% of dispersant, 0.5% of ester alcohol and 0.2% of functional fiber into the formula with 13% of styrene-acrylic emulsion, 0.1% of coupling agent and 0.1% of wetting agent In the mixing tank of the mixed liquid, start the agitator, and add thickener 0.2% after mixing for 2 hours at a stirring speed of 120r / min;

[0019] Add 15% of hollow vitrified microspheres, 5% of aluminum silicate, 10.5% of pottery sand, 10% of building glue and 4.5% of polyphenylene particles at a stirring speed of 50r / min and stir for 1 hour to obtain a mixture, which is thermal insulation and waterproof Clay, PH value is 8.5.

Embodiment 2

[0021] Add 25.2% of sodium silicate aqueous solution, 0.5% of antifungal agent, 0.6% of dispersant, 0.8% of ester alcohol and 0.5% of functional fiber into the formula with 14% of styrene-acrylic emulsion, 0.4% of coupling agent and 0.6% of wetting agent In the mixing tank of the mixed solution, start the agitator, and add thickener 0.4% after mixing for 2.5 hours at a stirring speed of 130r / min;

[0022] Add 5% of hollow vitrified microspheres, 10% of aluminum silicate, 32% of pottery sand, 5% of construction glue and 5% of polyphenylene particles at a stirring speed of 55 r / min and stir for 1.5 hours to obtain a mixture, namely Thermal insulation and waterproof cement, PH value is 9.

Embodiment 3

[0024] Add 20% of sodium silicate aqueous solution, 0.9% of antifungal agent, 0.2% of dispersant, 1% of ester alcohol and 0.9% of functional fiber into the formula with 19% of styrene-acrylic emulsion, 0.7% of coupling agent and 0.9% of wetting agent In the mixing tank of the mixed liquid, start the agitator, at the stirring speed of 125r / min, add 0.8% thickener after mixing for 3 hours.

[0025] Add 20% hollow vitrified microspheres, 15% aluminum silicate, 13.1% pottery sand, 6.0% construction glue and 1.5% polyphenylene particles into the mixture at a stirring speed of 60 r / min and stir for 2 hours to obtain a mixture, that is, heat preservation Waterproof cement, PH value is 10.

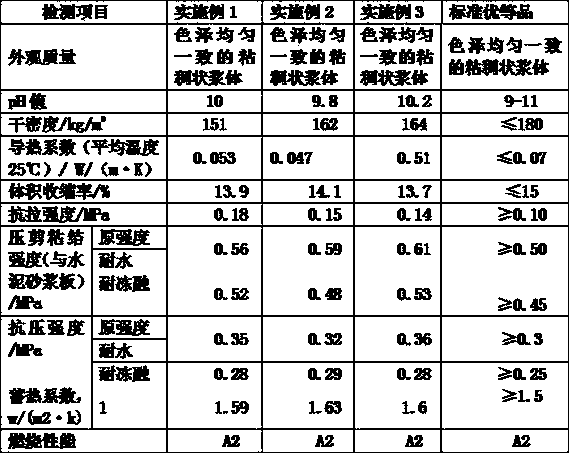

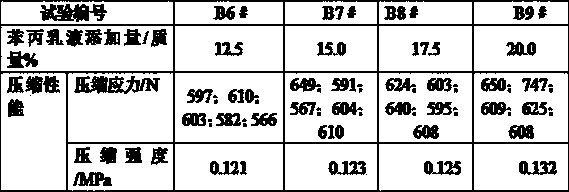

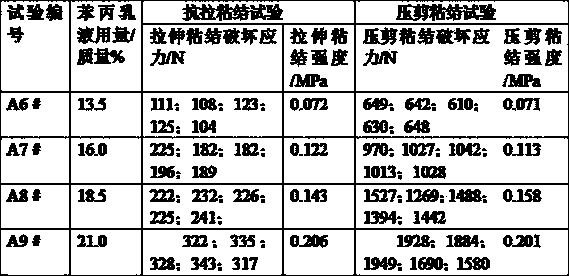

[0026] 1. The effect of the amount of styrene-acrylic emulsion on the performance of thermal insulation and waterproof cement.

[0027] Styrene-acrylic emulsion is the basic cementing substance of thermal insulation and waterproof mastic, and it is the source of the strength of thermal insulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive shear bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com