A curing system for polar plates

A plate and curing chamber technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of plate humidification, uneven heating, poor plate curing effect, small circulation distance, etc., to achieve good curing effect, uniform heating, gas The effect of low circulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

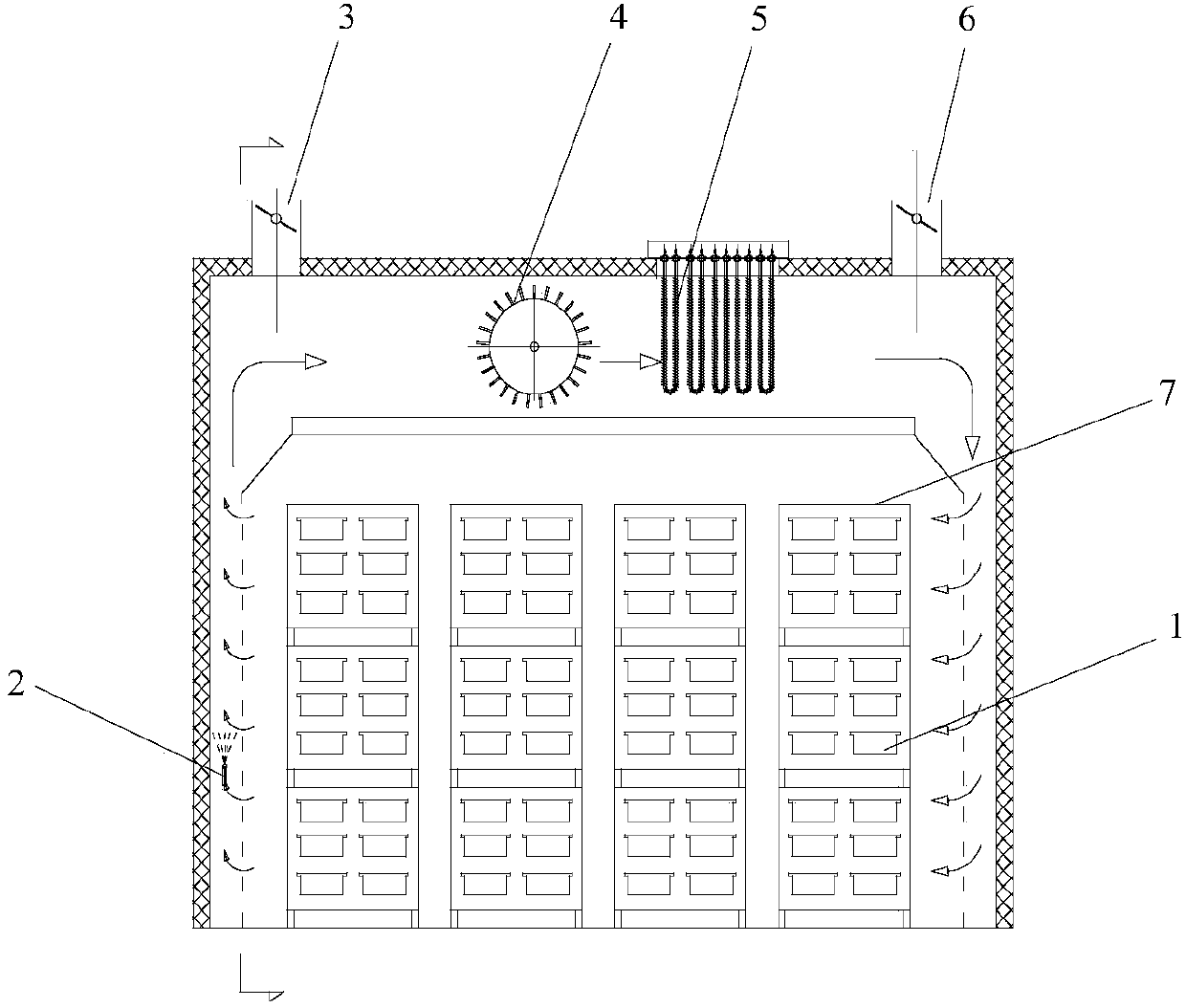

[0029] Such as Figure 2 to Figure 5 As shown, an embodiment of the curing system for pole plates of the present application includes a curing chamber, a first blower 200 and an adjustment device. The adjustment device is used to adjust the temperature and humidity in the curing chamber. The curing chamber includes a body 110 , a curing chamber door 120 and a partition 130 . The front end of the main body 110 is provided with a curing chamber door 120, which can be controlled pneumatically. The rear end of the main body 110 is a closed end. The space between the chamber 111 and the second chamber 112 , the curing chamber door 120 and the front end of the partition plate 130 forms a front turning air duct 140 . In one embodiment, the body 110 is in the shape of a cuboid, and the partition 130 completely separates the first cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com