Induction heating torsion system and method for torsion heating using same

A technology of induction heating and induction coil, applied in the field of heating system, can solve the problem that the quality of blades cannot be guaranteed, and achieve the effects of low scrap rate, uniform twist angle and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

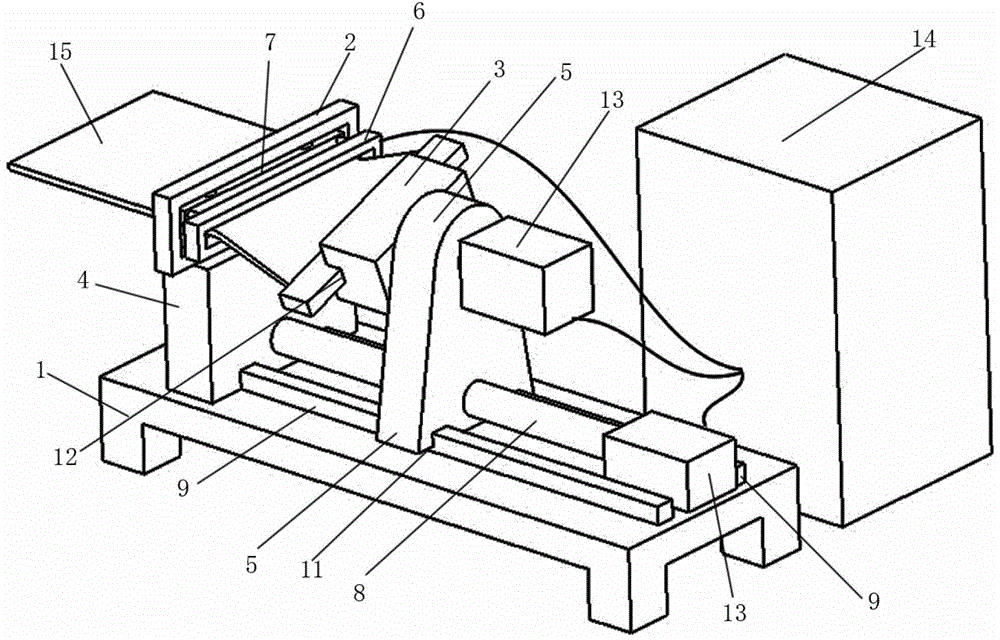

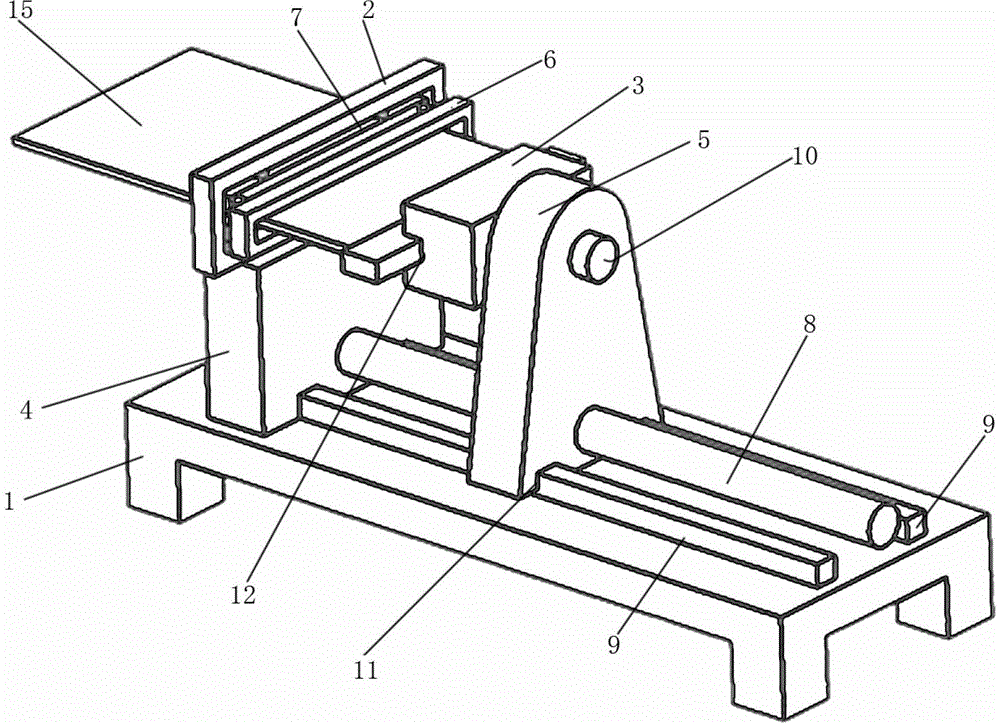

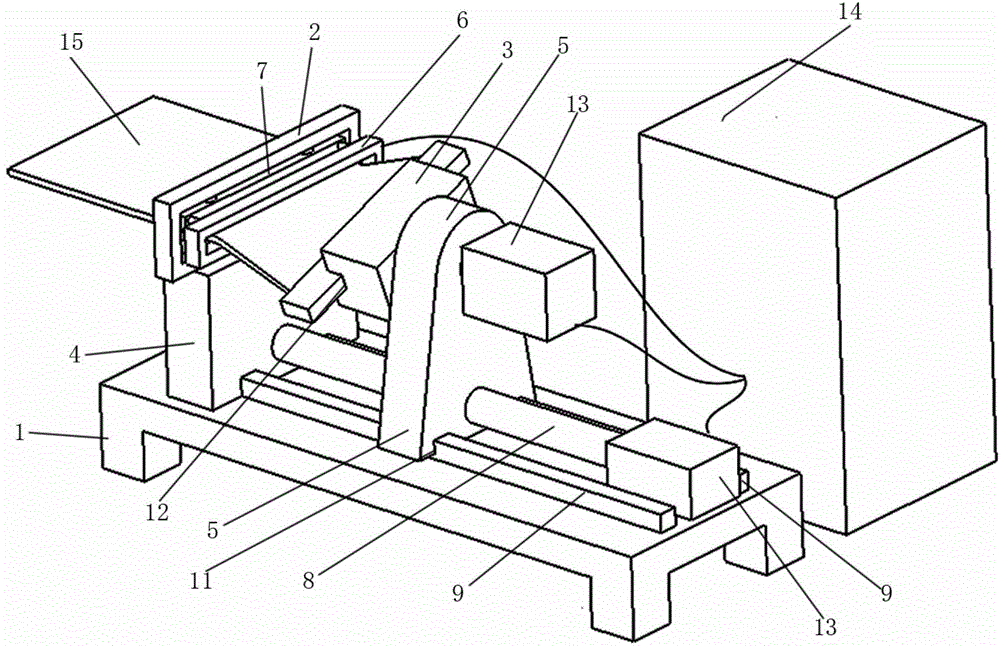

[0036] The following with attached Figure 1 to Figure 7 The induction heating torsion system of the present invention and the method for torsion heating using it are further described in detail.

[0037] For the induction heating torsion system of the present invention, please refer to Figure 1 to Figure 7, including a base 1, a clamping device, an induction coil 6, a sliding device, a driving device 13 and a twisting device, the twisting device includes a rotating shaft 10, the clamping device includes an induction chuck 2 and a twisting chuck 3, the The induction chuck 2 is fixed on the base 1, the rotating shaft 10 is rotatably erected on the base 1, the twisting chuck 3 is fixed to the end of the rotating shaft 10, and the twisting chuck 3 passes through The sliding device is slidably connected to the base 1, and the center of the induction chuck 2 is provided with a clamping opening 7 for the part 15 to pass through and clamp the part 15. The part 15 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com