AM(acrylamide) /AA(acrylic acid)/NVP(N-vinyl pyrrolidinone)/YEML quadripolymer oil-displacing agent and synthetic method thereof

A synthesis method and polymer technology, applied in drilling compositions, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of low viscosity retention rate, unreachable engineering construction, and reduced polymer fluidity control ability, etc. problems, to achieve good temperature and salt resistance, shear resistance, viscosity, temperature and salt resistance, and oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation of YEML monomer

[0019] Add 4.2g of maleic anhydride and 20mL of ethanol into a 100mL round-bottom flask, stir to dissolve completely; slowly add dropwise a mixed solution of 2mL of ethylenediamine and 20mL of ethanol into the round-bottom flask, and react at 50°C for 4 hours after the dropwise addition is complete ; The reaction product was filtered, washed with a large amount of deionized water, and finally dried at 60°C to obtain the modified functional monomer YEML.

Embodiment 2

[0020] Embodiment 2: the synthesis of tetrapolymer AM / AA / NVP / YEML

[0021] First add 0.0100g of YEML prepared above into a 250mL three-necked bottle according to the ratio in Table 1, then add 6.5000gAM, 3.4700gAA, 1.9085g sodium hydroxide and 0.0200g NVP to prepare the total monomer mass percentage concentration of 10%-20% aqueous solution, nitrogen gas for 30 minutes; then add the initiator ammonium persulfate solution and sodium bisulfite solution, the molar ratio of ammonium persulfate and sodium bisulfite is 1:1, and the amount of initiator added is the total monomer 0.1%-0.5% of the mass, continue to pass N 2 10-20min, react at a temperature of 30-60°C for 4-12h; finally wash with absolute ethanol, pulverize and dry to obtain AM / AA / NVP / YEML tetrapolymer.

[0022] Table 1 Quaternary polymer synthesis drug dosage

[0023] medicine

[0024] NaOH

Embodiment 3

[0025] Embodiment 3: AM / NaAA / NVP / YEML tetrapolymer structure characterization

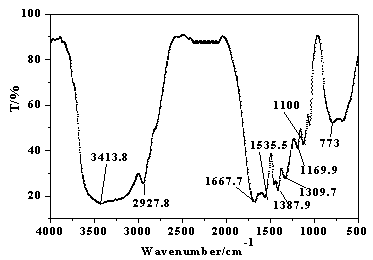

[0026] The infrared spectrogram of the tetrapolymer AM / AA / NVP / YEML synthesized by embodiment 2 is as follows figure 1 Shown; It can be seen from the figure that -C(O)NH 2 The stretching vibration peak is located at 3413.8cm -1 , the stretching vibration peak of -C=O is located at 1667.7cm -1 ,; the C-N stretching vibrations of primary and secondary amides are respectively at 1387.9 cm -1 and 1309.7cm -1 There is a strong absorption peak, on the NVP ring and C-N stretching vibration at 1169.9cm -1 and 1100cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com