Electrical system controlling dynamic compactor full-release winding braking and working method thereof

A technology of electrical system and dynamic tamping machine, which is applied in hoisting devices and other directions, can solve the problems of complex control system of controllable falling hoisting, cumbersome debugging, and high cost, so as to improve the efficiency of single tamping, reduce costs, and improve The effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

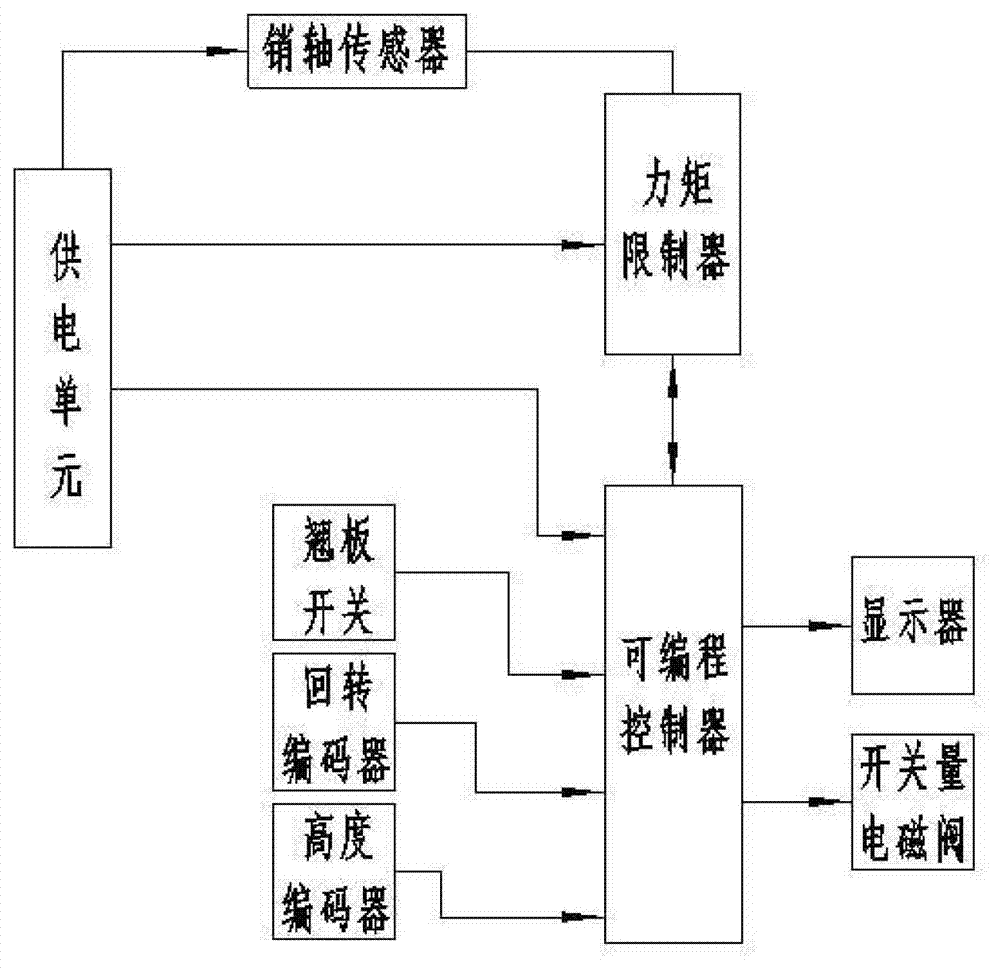

[0033] like figure 1 As shown, the present invention provides an electrical system for controlling the full release of the winch brake of the dynamic compaction machine, including: a height acquisition mechanism, namely a height encoder, the input end of the height encoder is connected to the winch motor of the dynamic compaction machine, and the height acquisition mechanism The mechanism collects the height position of the rammer of the dynamic compaction machine, and provides the first height position of the rising action of the rammer and the second height position of the lowering action of the rammer;

[0034] The tension collection mechanism includes a pin sensor and a torque limiter, the pin sensor and the torque limiter are respectively connected to the power supply unit, the pin sensor is located at the head of the main arm of the dynamic compaction machine, the pin sensor is in contact with the wire rope, and the pin sensor The output end of the torque limiter is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com