Pneumatic glue gripping device

A pneumatic and cylinder push rod technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity and low handling efficiency, and achieve the effect of reducing labor intensity, improving work efficiency and increasing friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

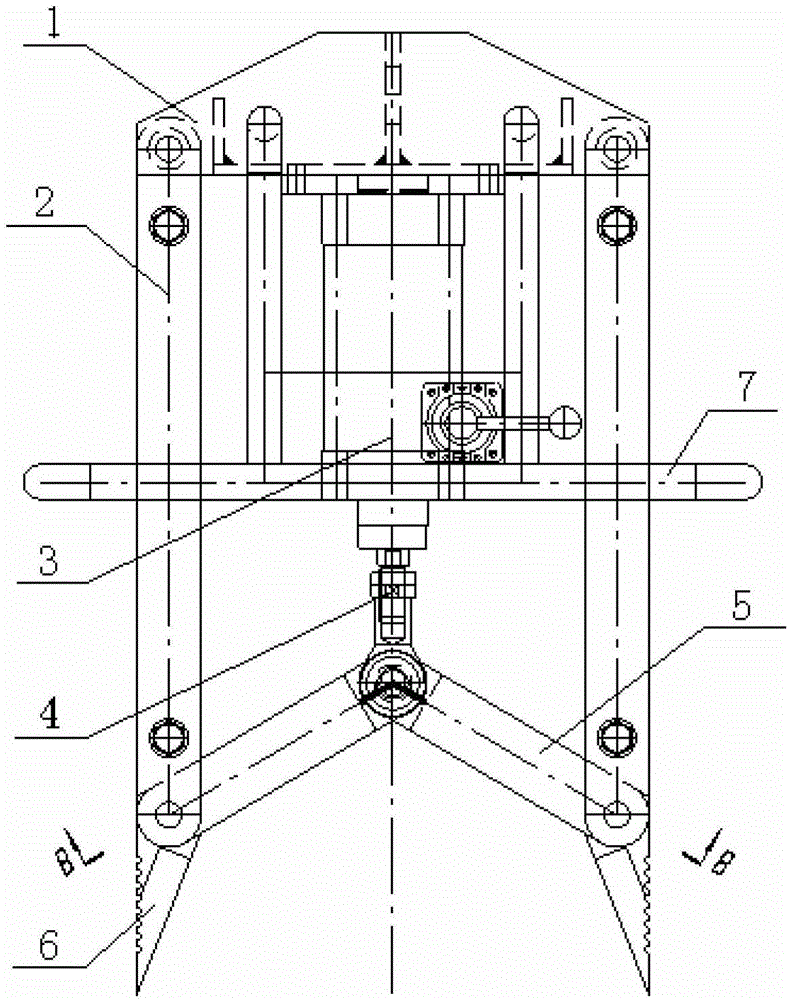

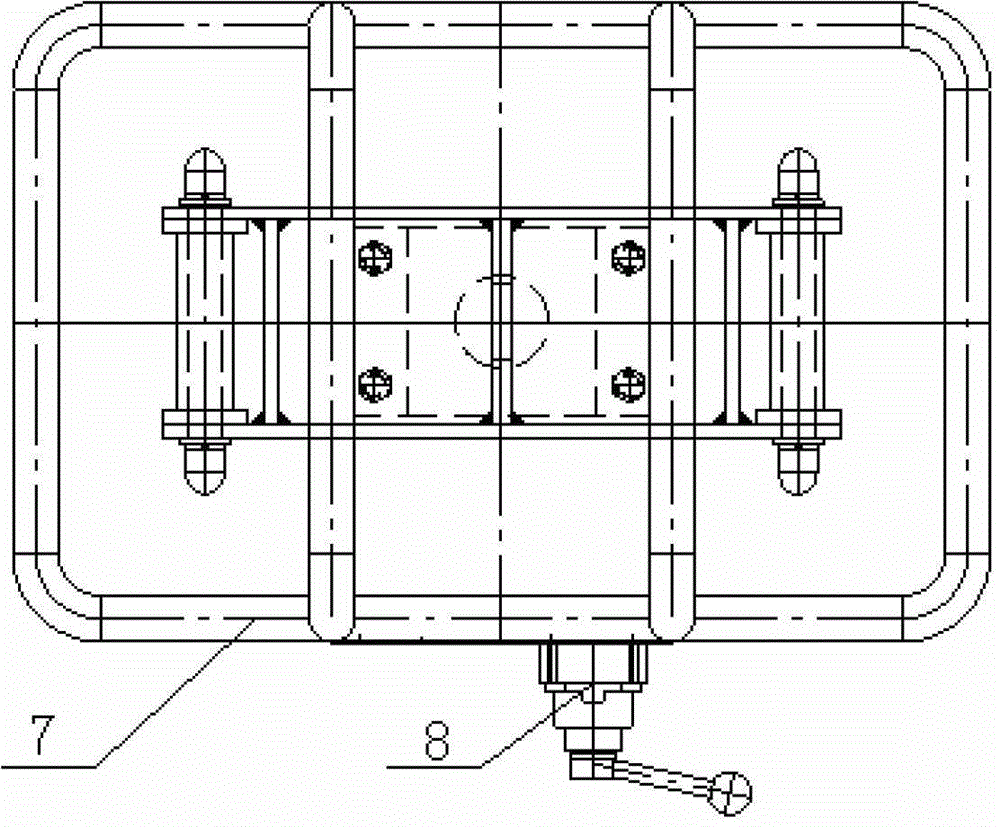

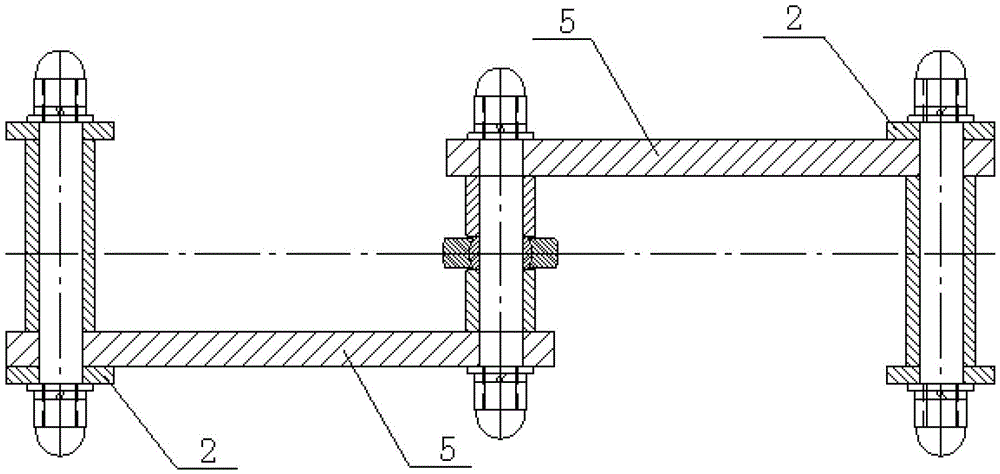

[0023] like Figure 1 to Figure 7 As shown, a specific embodiment of the present invention is given.

[0024] like figure 1 , figure 2 , image 3 Shown, a kind of pneumatic glue gripper, comprises the base 1 that is used to connect hoisting device and the driving device under the base 1, transmission mechanism and grasping device, and described driving device is the cylinder 3 that is installed under the base 1; Described includes the swing arm 2 that is symmetrically arranged at the lower end of the base 1 and the cylinder push rod at the lower end of the cylinder 3. The grabbing device is a pair of grabbing knives that are symmetrically arranged at the lower end of the swing arm 2, including a knife handle 5 and a knife head 6. The knife handle 5 and the cutter head 6 are of an integrated structure, and the two form an angle of 120 degrees. The upper ends of the two knife handles 5 are jointly hinged with the connecting rod at the lower end of the cylinder push rod, and ...

Embodiment 2

[0031] The handle of the grabbing knife and the cutter head form an integral crescent shape, the middle part of the grabbing knife is hinged with the lower end of the swing arm, and the upper ends of the handles of the two grabbing knives are jointly hinged with the connecting rod at the lower end of the cylinder push rod.

[0032] Others are the same as in Example 1.

[0033] The invention adopts the cylinder as the drive, and through the transmission of the connecting rod mechanism, it drives the grasping knives set opposite to grab the rubber material. The friction coefficient makes it more firm, fast and convenient to grab the rubber material, effectively reduces the labor intensity and improves the work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com