Anti-corrosion durable flange plate

A flange and durable technology, applied in the direction of flange connection, pipeline anti-corrosion/rust protection, damage protection, etc., can solve the problems of high cost, easy wear, and poor wear resistance, so as to improve anti-corrosion and wear resistance , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

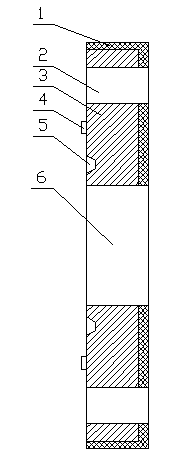

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, an anti-corrosion and durable flange of the present invention includes a flange body 3, a nozzle 6 and a bolt hole 2, a nozzle 6 is arranged in the center of the flange body 3, and a plurality of bolt holes are arranged on the flange body 3 2. The bolt holes 2 are located on the outer periphery of the nozzle 6, and also include a protective layer 1, which is glued on the outer surface of the flange body 6.

[0014] As a further improvement of the present invention, the material of the protective layer 1 is polytetrafluoroethylene. The protective layer 1 can be made of various plastics or other anti-corrosion materials, preferably polytetrafluoroethylene is waterproof, has good anti-corrosion performance and high wear resistance.

[0015] As a further improvement of the present invention, a sealing groove 5 is formed on the inner end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com