Manganese zinc ferrite material for eddy current type approach switch, film-coated magnetic core and preparing method of manganese zinc ferrite material

A manganese-zinc ferrite and proximity switch technology, which is applied in the field of soft ferrite, can solve the problems affecting the sensitivity of proximity switches, electromagnetic environment interference, limited sensing distance and sensing sensitivity improvement, etc., to enhance the bonding force and reduce costs , the effect of increasing the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described below based on specific examples, but the present invention is not limited to these examples.

[0042] The manganese-zinc ferrite material for the eddy current proximity switch of the embodiment of the present invention is manufactured by the traditional oxide method, and the specific steps are as follows:

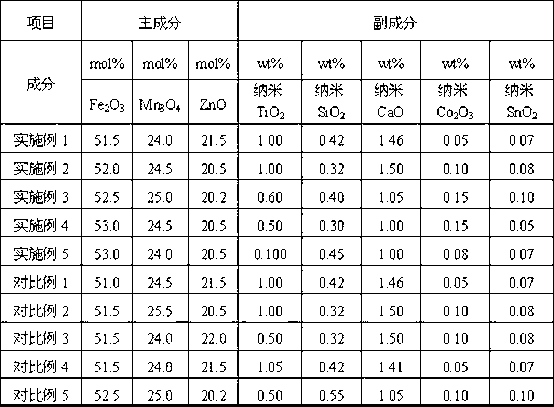

[0043] (1) Mixing: Dry mixing is carried out after mixing the ingredients according to the ratio of the main components shown in Table 1, and the mixing time is 60-70 minutes;

[0044] (2) Pre-burning: pre-fire the mixed materials in a pusher kiln, the pre-fire temperature is controlled at 930±20°C, and the pre-fire time is 140~240 minutes;

[0045] (3) Grinding: add the sub-components shown in Table 1 to the calcined material of the main component obtained in the previous step, and then carry out wet grinding. The grinding time is 120-150 minutes, and the particle size of the slurry after grinding is controlled at 0.5- 1.2μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com