Force measurement device of tensioner

A force measuring device and tensioner technology, applied in the mechanical field, can solve problems such as high cost, limited use conditions, complex structure, etc., and achieve the effect of compact structure, high practical value, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

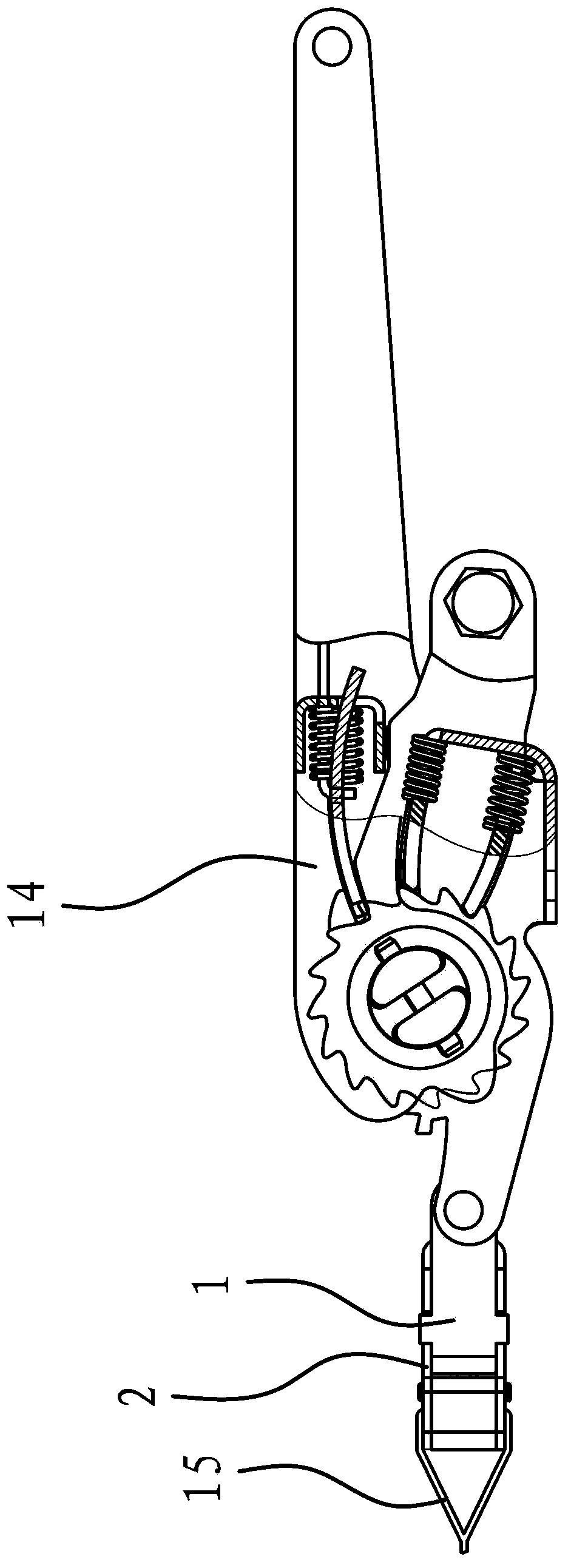

[0045] Such as figure 1 As shown, the force measuring device of the tensioner includes a movable part 2 and a fixed part 1, the fixed part 1 is used to be fixedly connected with the tensioner 14, and the movable part 2 is used to be connected with the binding belt 15. During the binding operation of the tensioner, the operator can know the current binding force through this device.

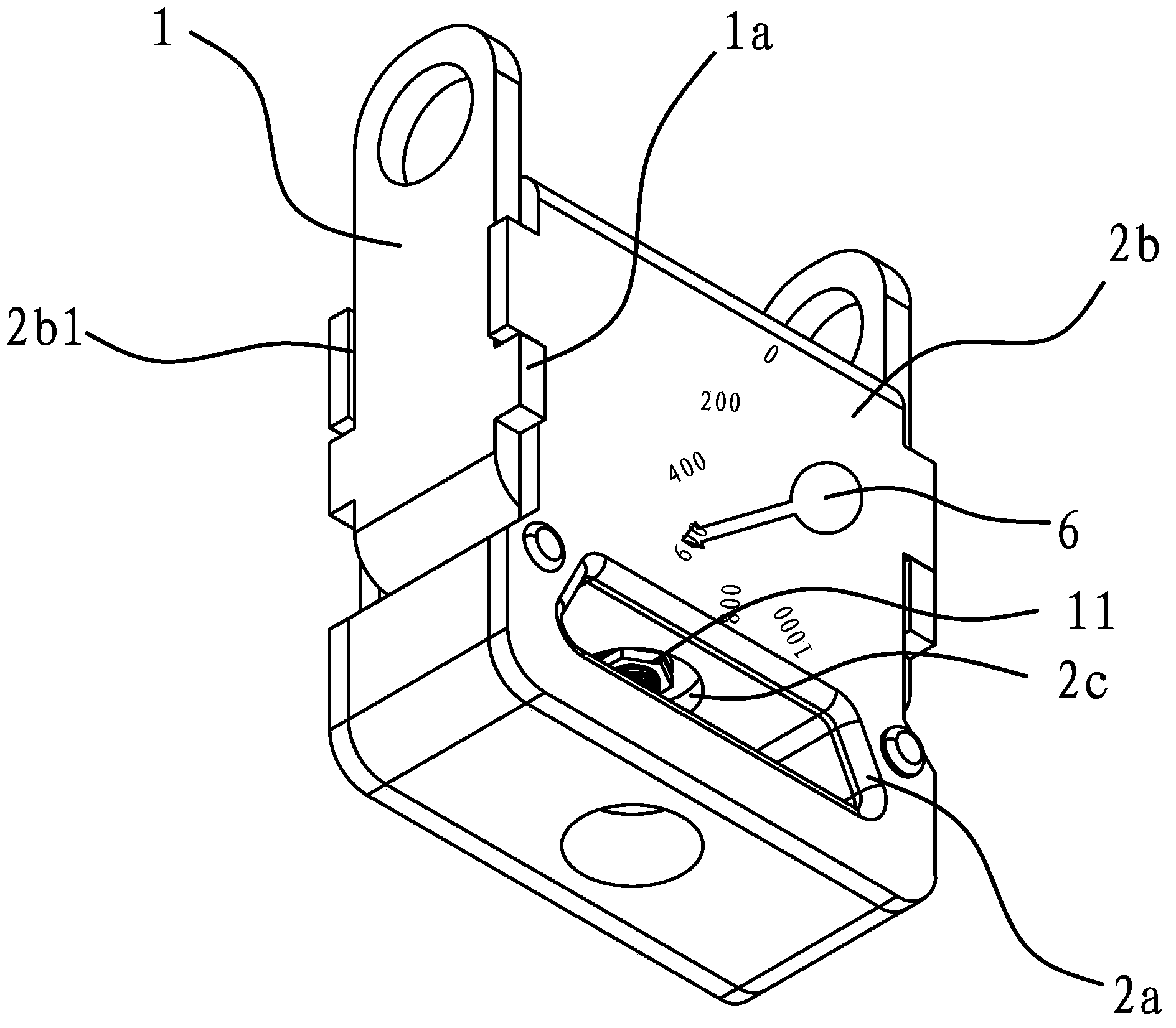

[0046] There is a guide structure between the fixed part 1 and the movable part 2, and the movable part 2 is translated relative to the fixed part 1 through the guide structure.

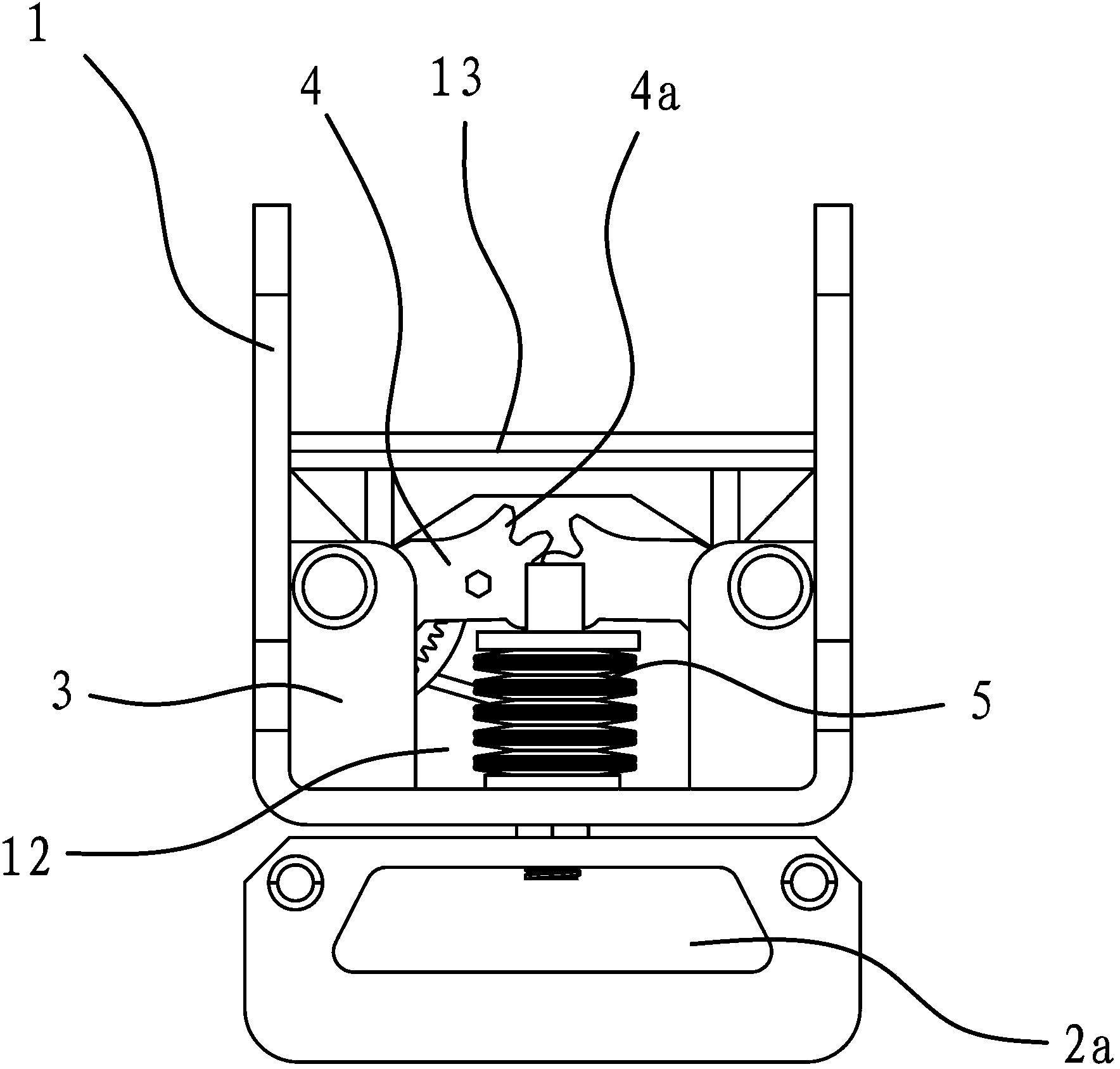

[0047] The fixing part 1 is U-shaped, and the U-shaped notch of the fixing part 1 is fixedly connected with a fixing seat 3 , and the inner end of the load-bearing lever 4 is hinged on the fixing seat 3 .

[0048]The movable part 2 includes a guide part 2b and a connecting part 2a for linking with the binding band 15, the guiding part 2b is located at the U-shaped notch of the fixed part 1, the connecting part 2a is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com