Cloth control method for cloth equipment and cloth equipment

A control method and cloth technology, applied in the direction of flow control, computer control, general control system, etc., can solve the high cost of carbon fiber manufacturing, the reliability of corrosion resistance performance needs to be verified, and the cost increases. New material process adaptability and use adaptability and other issues, to achieve the effect of reducing design weight, reducing reinforcements, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

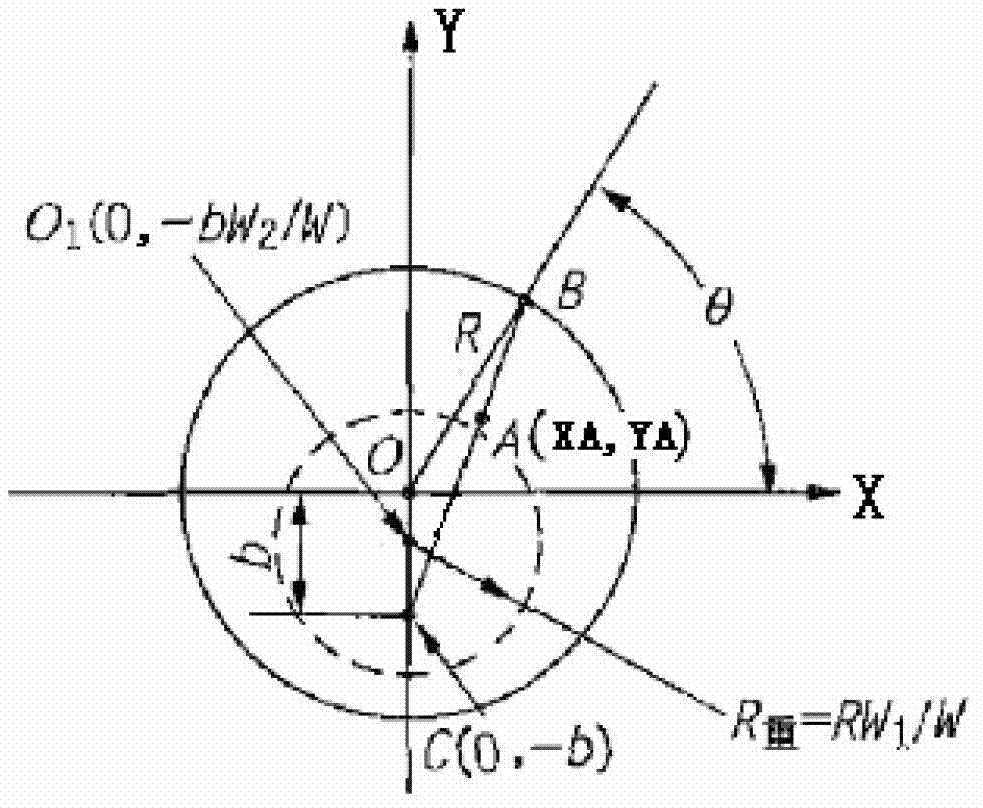

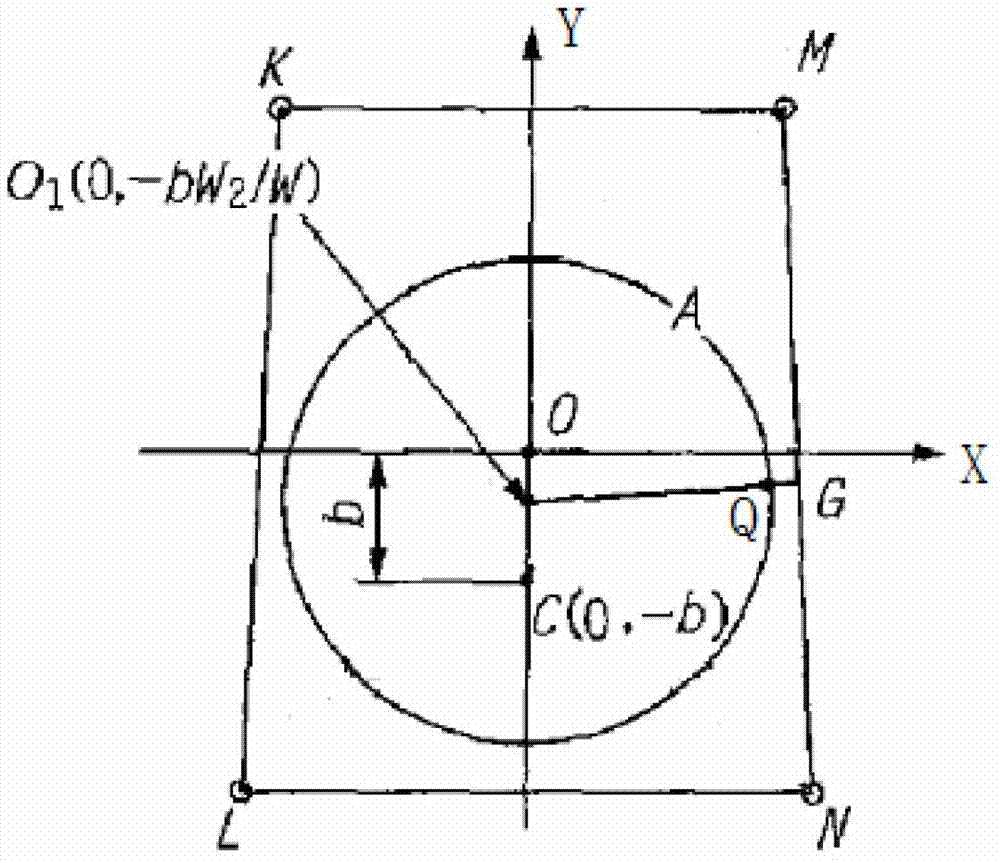

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

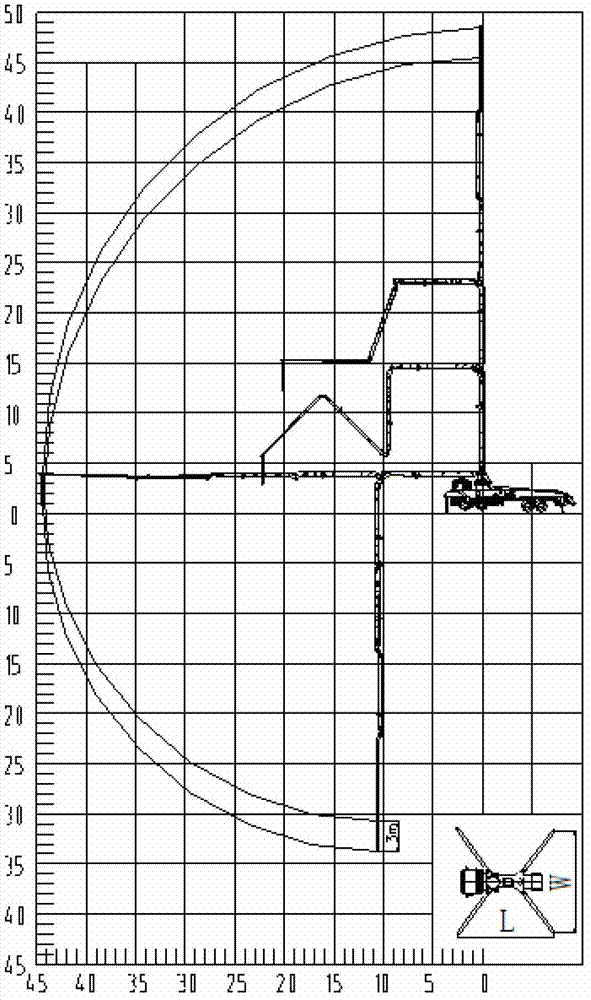

[0038] First of all, it should be noted that although the concrete pump truck is used as an example to describe the distribution control method of the distribution equipment of the present invention, it is obvious to those skilled in the art that the distribution control method of the distribution equipment of the present invention is not limited to be applied to concrete pump trucks , but can be applied to any distribution equipment with a distribution boom, such as concrete distribution trucks, concrete distribution trailers, etc. In addition, the distribution control method of the distribution equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com