Automatic tensioning oil cylinder

An oil cylinder, automatic technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of reducing service life, increasing operating strength, manual adjustment, etc., and achieving the effect of simple structure and convenient modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

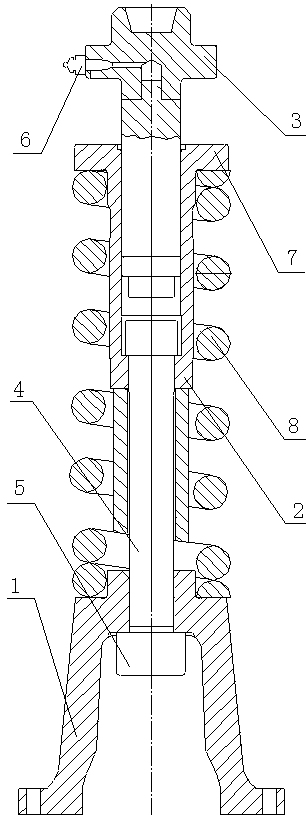

[0010] See figure 1 , The present invention relates to an automatic tensioning cylinder, including a base frame 1, the base frame 1 is provided with a cylinder block 2, the bottom end of the cylinder block 2 is equipped with a tie rod 4, the tie rod 4 is fixed to the cylinder by a nut 5 On the body 2, the top of the cylinder 2 is equipped with a handle 3, the handle 3 is in the shape of a "T", and the side of the handle 3 is provided with an oil injection valve 6 which communicates with the inside of the cylinder 2. 2 The outer wall is equipped with a spring 8. The bottom of the spring 8 is placed on the base frame 1, and the top is provided with a spring cover 7, which is fixed on the outer wall of the cylinder 2 for limiting the position of the spring 8.

[0011] This kind of automatic tensioning oil cylinder has a certain pre-tensioning force through the spring outside the cylinder, and can automatically adjust the tension of the crawler through the spring. This kind of automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com