Fractal yagi printed antenna of coplanar waveguide feed

A technology of coplanar waveguide and printed antenna, applied in the field of fractal Yagi printed antenna, can solve the problems of bulky antenna, unfavorable miniaturization, mass production, and complexity, and achieve compact feeding form, favorable miniaturization, and high gain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

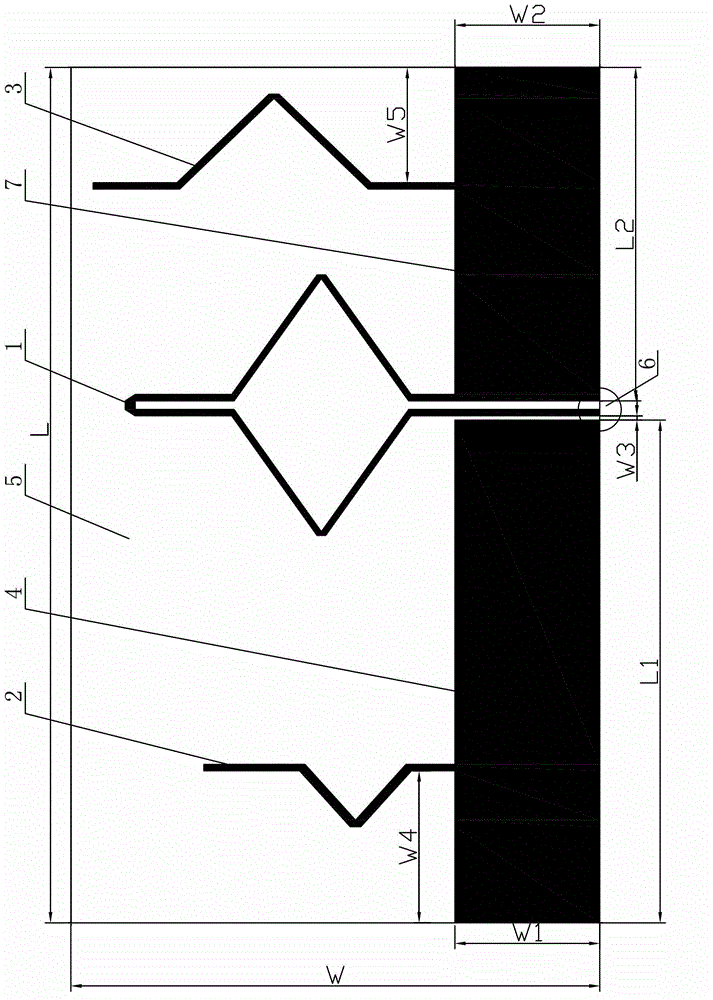

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment mode. A coplanar waveguide-fed fractal Yagi printed antenna described in this embodiment mode includes an active vibrator 1, a director 2, a reflector 3, a first printed metal floor 4, a dielectric board 5, a common The surface waveguide feed port 6 and the second printed metal floor 7, the first printed metal floor 4, and the second printed metal floor 7 are arranged in the lower part of one side surface of the dielectric board 5 in a straight line, and the director 2, The active vibrator 1 and the reflector 3 are installed on one side surface of the dielectric board 5 in sequence from left to right. The left arm and the right arm of the lower part of the active vibrator 1 are located on the first printed metal floor 4 and the second printed metal floor. Between the floors 7, and the left arm of the lower part of the active vibrator 1 is in contact with the lower edge of one side surface of the...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the length L of the dielectric board 5 of the coplanar waveguide-fed fractal Yagi printed antenna described in this embodiment is 170mm-175mm, and the width W of the dielectric board 5 is 85mm-90mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the length L1 of the first printed metal floor 4 of the fractal Yagi printed antenna described in this embodiment is 100mm-105mm, and the width W1 of the first printed metal floor 4 is 30mm -35mm, the length L2 of the second printed metal floor 7 is 60mm-65mm, and the width W2 of the second printed metal floor 7 is the same as the width W1 of the first printed metal floor 4 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com