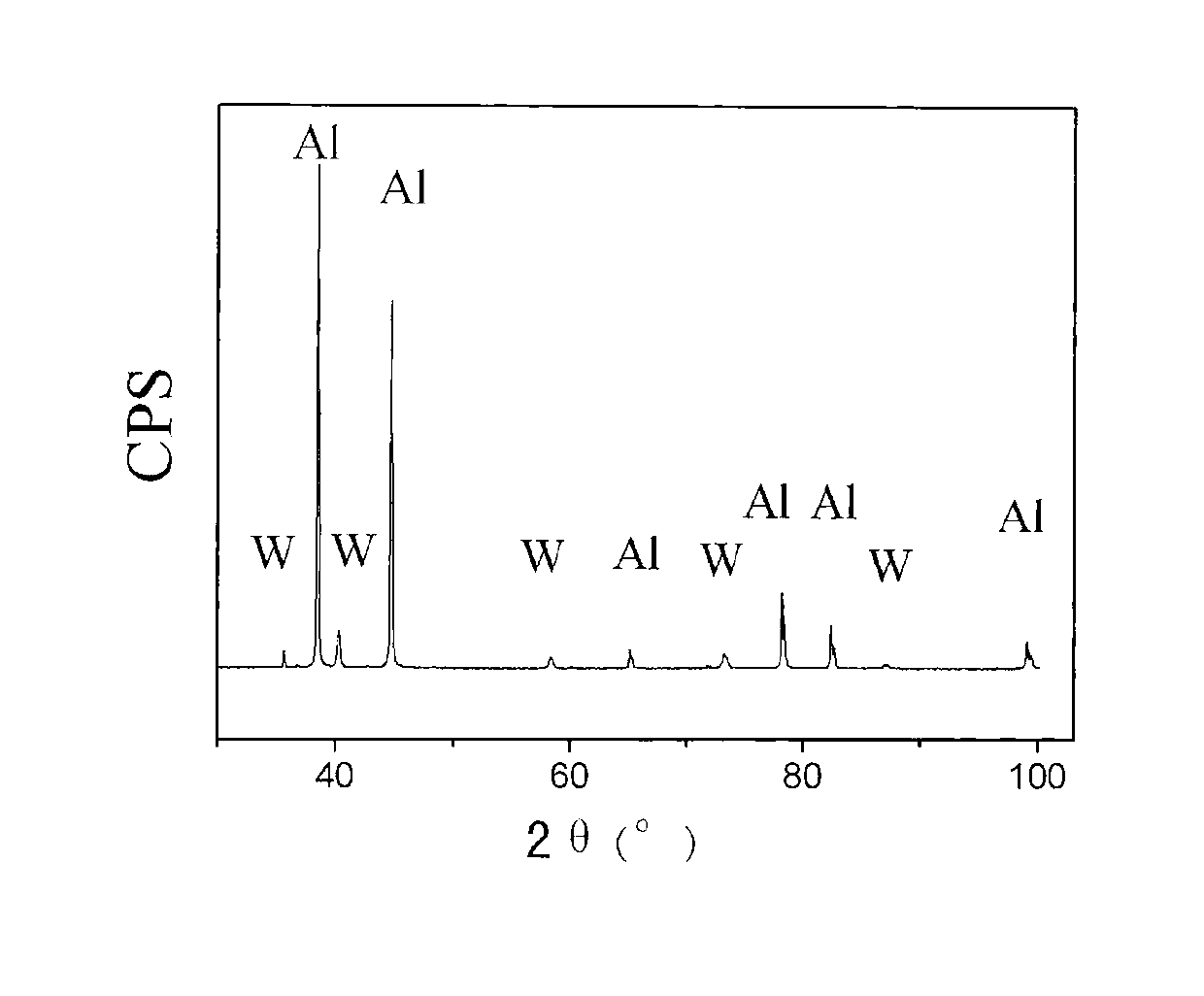

Aluminum-tungsten composite and production method thereof

A technology for composite materials and plates, which is applied in the field of metal composite materials and their preparation, can solve the problems that pure metal particle reinforced aluminum matrix composite materials have not yet been discovered, and achieve the effect of improved mechanical properties and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

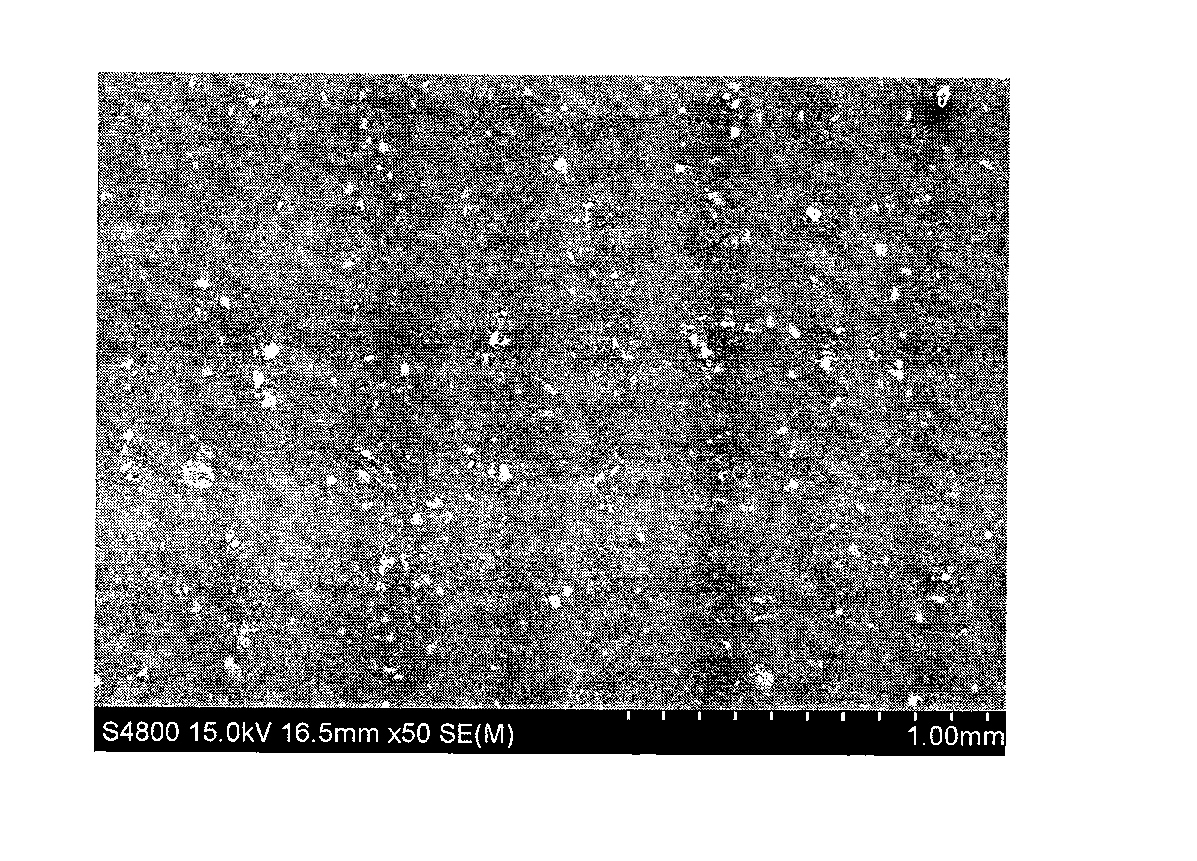

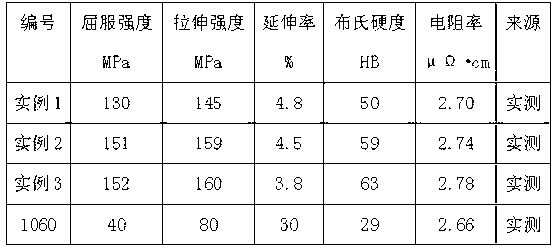

Embodiment 1

[0016] The surface of an annealed 1060 industrial pure aluminum plate (produced by Southwest Aluminum Co., Ltd.) with a size of 150mm×100mm×7mm was polished with a wire brush, and then cleaned with alcohol. Spread 14g of pure tungsten particles (produced by Shanghai Shuitian Material Technology Co., Ltd.) with a diameter of 10-15μm evenly between two aluminum plates, put the two aluminum plates into a muffle furnace at a temperature of 280°C and heat for 5 minutes Finally, it is rolled on a rolling mill with a diameter of 300 mm and a length of 220 mm. No lubricating oil was used during rolling, and the rolling speed and reduction were 0.6 m / s and 50%, respectively. Cool to room temperature in air after rolling. Cut off the composite plate after the first rolling from the middle, polish and clean the surface of the plate with a steel brush and alcohol respectively, and evenly lay pure tungsten particles with the same quality as the first pass between the two cut plates (14g)...

Embodiment 2

[0018] The surface of an annealed 1060 industrial pure aluminum plate (produced by Southwest Aluminum Co., Ltd.) with a size of 150mm×100mm×7mm was polished with a wire brush, and then cleaned with alcohol. Spread 29g of pure tungsten particles (produced by Shanghai Shuitian Material Technology Co., Ltd.) with a diameter of 10-15μm evenly between two aluminum plates. After stacking the two aluminum plates, put them into a muffle furnace at a temperature of 350°C and heat for 10 minutes. Finally, it is rolled on a rolling mill with a diameter of 300 mm and a length of 220 mm. No lubricating oil was used during rolling, and the rolling speed and reduction were 0.4 m / s and 50%, respectively. Cool to room temperature in air after rolling. Cut off the composite plate after the first rolling from the middle, polish and clean the surface of the plate with a steel brush and alcohol respectively, and evenly lay pure tungsten particles with the same quality as the first pass between th...

Embodiment 3

[0020] The surface of an annealed 1060 industrial pure aluminum plate (produced by Southwest Aluminum Co., Ltd.) with a size of 150mm×100mm×7mm was polished with a wire brush, and then cleaned with alcohol. Spread 44.3 g of pure tungsten particles (produced by Shanghai Shuitian Material Technology Co., Ltd.) with a diameter of 10-15 μm evenly between two aluminum plates. After stacking the two aluminum plates, put them into a muffle furnace at a temperature of 310 °C and heat for 20 Rolling is carried out after 10 minutes on a rolling mill with a diameter of 300 mm and a length of 220 mm. No lubricating oil was used during rolling, and the rolling speed and reduction were 0.8 m / s and 50%, respectively. Cool to room temperature in air after rolling. Cut off the composite plate after the first rolling from the middle, polish and clean the surface of the plate with a steel brush and alcohol respectively, and evenly lay pure tungsten particles with the same quality as the first p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com