Constant temperature control system for microwave chemical reactor

A chemical reactor and constant temperature control technology, applied in the field of chemical reactors, can solve the problems of affecting the effect of the reaction, inability to accurately control the temperature, etc., and achieve the effect of reliable temperature protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

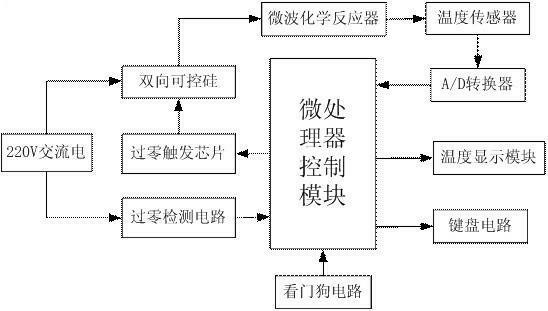

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a microwave chemical reactor constant temperature control system includes a microprocessor control module, the microprocessor control module is connected with a bidirectional thyristor and a temperature sensor, and the bidirectional thyristor is connected to a 220V AC power supply, a microwave chemical The reactors are connected; the temperature sensor is connected with the microwave chemical reactor, the microprocessor control module is also connected with a keyboard circuit, and the bidirectional thyristor is connected with the microprocessor control module through a zero-crossing trigger chip .

[0014] The temperature in the reactor is collected by the temperature sensor, processed by the microprocessor control module, and the collected temperature is compared with the temperature set by the keyboard circuit, and the PID control a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com